|

Resources: MMP / DEP / OTA / TURI |

| index / resources / tools / case studies / Sectors |

Overview of Plating Process: Electroless Plating |

Figure 1

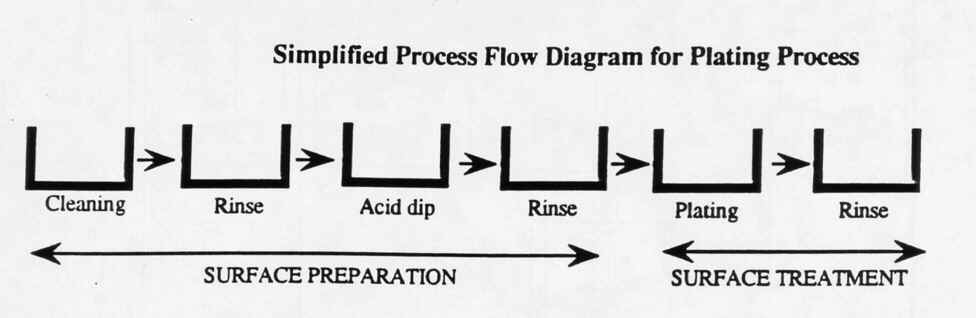

B. Electroless Plating According to one industry source,6 approximately 15% of the metal finishers in Massachusetts (179 of 1,231) perform electroless plating, which relies on chemical reduction of metal ions on the substrate surface rather than on electrical currents. Electroless plating baths, which contain a variety of chelating and/or complexing agents to hold the metals in solution, are more sensitive than electroplating baths to changes in pH and temperature. The most widely used electroless plating metals are nickel, copper, cobalt, and gold.7 Electroless nickel is used in aerospace, plastics, automotive, and electronics manufacturing to plate non-conductive (e.g. plastic) substrates and to provide aluminum with a solderable surface. Electroless copper is used on non-conductive substrates in printed circuit board manufacturing.8 Figure 2 presents a simplified process flow diagram for an electroless plating process: Figure 2

Sectors - Metal Finishing |

| index / resources / tools / case studies | |

| introduction / profile / production / implementation / laws & regulations | |

Comments are

encouraged

Created by the Environmental Integration

Initiative

Revised: 05/03/02

URL: http://www.mmpmfg.org/cleaner/