| Ag 101 | ||

|

|

|||||||||

|

Crop Production

For each component, the operations and when they need to be carried out, the machinery or equipment farmers use, potential environmental concerns related to that component, and best management practices recommended to minimize environmental problems will be described.

BackgroundGrowing crops for food was one of the first priorities of the earliest settlers arriving in North America. With shipboard supplies depleted, and having little familiarity with the land and native vegetation, groups arriving from Europe were quickly forced to learn to produce crops to ensure their survival. The stories of Native Americans teaching the settlers to plant and fertilize a corn crop are part of this country’s lore. In the era of Thomas Jefferson (arguably the most illustrious farmer that this nation has produced), farmers made up about 90% of the work force. As late as 1900, almost 40% of the labor force was engaged in producing crops and livestock for food, feed, and fiber. Now, with less than one percent of our population claiming farming as a principal occupation, most U.S. citizens have little or no crop production experience. This section provides an overview of the principles and practices associated with production of the major crops grown in the United States. Major Crops Grown in the United StatesIn round numbers, U.S. farmers produce about $100 billion worth of crops and about $100 billion worth of livestock each year. Production data from the year 2000 for major agricultural crops grown in this country are highlighted in the following table:

Corn: The United States is, by far, the largest producer of corn in the world. Corn is grown on over 400,000 U.S. farms. In 2000, the U.S. produced almost ten billion bushels of the world’s total 23 billion bushel crop. Corn grown for grain accounts for almost one quarter of the harvested crop acres in this country. Corn grown for silage accounts for about two percent of the total harvested cropland or about 6 million acres. The amount of land dedicated to corn silage production varies based on growing conditions. In years that produce weather unfavorable to high corn grain yields, corn can be “salvaged” by harvesting the entire plant as silage. According to the National Corn Growers Association, about eighty percent of all corn grown in the U.S. is consumed by domestic and overseas livestock, poultry, and fish production. The crop is fed as ground grain, silage, high-moisture, and high-oil corn. About 12% of the U.S. corn crop ends up in foods that are either consumed directly (e.g. corn chips) or indirectly (e.g. high fructose corn syrup). It also has a wide array of industrial uses including ethanol, a popular oxygenate in cleaner burning auto fuels. Soybeans: Approximately 2.8 billion bushels of soybeans were harvested from almost 73 million acres of cropland in the U.S. in 2000. This acreage is roughly equivalent to that of corn grown for grain. Over 350,000 farms in the United States produce soybeans, accounting for over 50% of the world’s soybean production and $6.66 billion in soybean and product exports in 2000. Soybeans represented 56 percent of world oilseed production in 2000. Soybeans are used to create a variety of products, the most basic of which are soybean oil, meal, and hulls. According to the United Soybean Board, soybean oil, used in both food manufacturing and frying and sautéing, represents approximately 79 percent of all edible oil consumed in the United States. Soybean oil also makes its way into products ranging from anti-corrosion agents to Soy Diesel fuel to waterproof cement. Over 30 million tons of soybean meal are consumed as livestock feed in a year. Even the hulls are used as a component of cattle feed rations. Hay: Hay production in the United States exceeds 150 million tons per year. Alfalfa is the primary hay crop grown in this country. U.S. hay is produced mainly for domestic consumption although there is a growing export market. According to the National Hay Association, the most common exports are timothy, some alfalfa, sudangrass, and bermudagrass hay. Hay can be packaged in bales or made into cubes or pellets. Hay crops also produce seeds that can be used for planting or as specialized grains. Wheat: Over 240,000 farms in the United States produce wheat. The U.S. produces about 13% of the world’s wheat and supplies about 25% of the world’s wheat export market. About two-thirds of total U.S. wheat production comes from the Great Plains (from Texas to Montana). Wheat is classified by time of year planted, hardness, and color (e.g. Hard Red Winter (HRW)). The characteristics of each class of wheat affect milling and baking when used in food products. Of the wheat consumed in the United States, over 70% is used for food products, about 22% is used for animal feed and residuals, and the remainder is used for seed. Cotton: Fewer than 32,000 farms in the United States produce cotton. Cotton is grown from coast-to-coast, but in only 17 southern states. Farms in those states produce over 20% of the world’s cotton with annual exports of more than $3 billion. The nation’s cotton farmers harvest about 17 million bales or 7.2 billion pounds of cotton each year. Cotton is used in a number of consumer and industrial products and is also a feed and food ingredient. Over 60% of the annual cotton crop goes into apparel, 28 percent into home furnishings, and 8 percent into industrial products each year. Cottonseed and cottonseed meal are used in feed for livestock, dairy cattle, and poultry. Cottonseed oil is also used for food products such as margarine and salad dressing. Grain sorghum: In the United States, grain sorghum is used primarily as an animal feed, but is also used in food products and as an industrial feedstock. Industrial products that utilize sorghum include wallboard and biodegradable packaging materials. Worldwide, over half of the sorghum grown is for human consumption. Some farmers grow sorghum as a hedge against drought. This water-efficient crop is more drought tolerant and requires fewer inputs than corn. Kansas, Texas, Nebraska, Oklahoma, and Missouri produce most of the grain sorghum grown in this country. The U.S. exports almost half of the sorghum it produces and controls 70% to 80% of world sorghum exports. As much as 12% of domestic sorghum production goes to produce ethanol and its various co-products. With demand for renewable fuel sources increasing, demand for co-products like sorghum-DDG (dry distillers grain) will increase as well due the sorghum's favorable nutrition profile. Rice: Just over 9,000 farms produce rice in the United States. Those farms are concentrated in six states: Arkansas, California, Louisiana, Mississippi, Missouri, and Texas. U.S. rice production accounts for just over 1% of the world’s total, but this country is the second leading rice exporter with 18% of the world market. About 60% of the rice consumed in the U.S. is for direct food use; another 20% goes into processed foods, and most of the rest into beer. Crop Production Systems

Of the seven crops listed, six are annual crops that must be replanted each year (only hay crops would be left in place from year to year). The process of cultivating crops typically begins with tillage of the soil. Although tillage can serve a number of functions within a crop production system, the most fundamental function is to create conditions that will ensure good contact between seed and soil at the time of seed planting and the ready availability of water to the seed during germination. The degree to which the soil is disturbed by tillage prior to seed planting provides a means of categorizing crop production within a range of tillage systems. These systems range from no-tillage in which there is not soil disturbance in a field except during the process of planting a crop to conventional tillage in which multiple tillage operations can extend over many months and take place before, during, and after planting. Crop production systems that involve pre-plant tillage but maintain residues from a previous crop on the soil surface are referred to as conservation tillage practices. For the major row crops produced in the United States, farmers use a range of production practices. Conventional tillage (also known as intensive tillage) usually involves a series of field operations that result in a residue-free soil surface at the time a crop is planted. Conventional tillage systems developed in this country to take advantages of the following benefits:

The major disadvantage of conventional tillage is the susceptibility of "unprotected" soil to erosion by water or by wind. Tillage is also energy-intensive, requiring large inputs of machine work and numerous trips across a field during a single growing season. Conventional tillage was "standard operating procedure" in the era before effective chemical weed and pest control strategies were available to farmers. Concerns about soil erosion led to the development of crop production strategies that retained crop residues on the soil surface. Conservation tillage requires more sophisticated implements that are capable of producing a seedbed while leaving a portion of surface residues undisturbed. Reduced tillage usually leaves 15% to 30% residue coverage on the soil surface. True conservation tillage is any tillage method that leaves at least 30% residue coverage on the soil after a crop has been planted. It can be accomplished through no-till, strip-till, ridge-till, or mulch till practices. Organic Farming

|

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

(Source: USDA - National Resources Conservation Service) |

Prior to planting, the soil needs to be prepared, usually by some form of tillage or chemical "burn-down" to kill the weeds in the seedbed that would crowd out the crop or compete with it for water and nutrients. Tillage methods can be divided into three major categories, depending on the amount of crop residue they leave on the surface. Residue slows the flow of runoff that can displace and carry away soil particles.

Herbicides are used in all these methods to kill weeds. In no-till systems, the herbicide is applied directly on last season's crop residue. In the other methods, some soil preparation takes place before the herbicide is applied. A common myth is that more herbicide is used with conservation tillage methods, but in fact farmers rely on herbicides for weed control under all tillage systems, and the amount used is more or less independent of tillage method.

(Source: USDA - National Resources Conservation Service) |

|

| Farm tractor and tillage implement |

| (Source: Daniel R. Ess, Purdue University) |

|

|

| Rubber-tracked tractor and moldboard plow at work in the field. |

| (Source: farmphoto.com) |

The moldboard plow has a large frame that is equipped with a series of “bottoms,” each of which consists of a steel coulter to slice through residue followed closely by a steel share that cuts the soil and an attached moldboard that is used to raise and turn over the cut “slice” of soil.

Disk plows work in a similar manner to laterally displace and invert soil through the use of concave steel disk blades.

Chisel plows use curved shanks to penetrate and “stir” the soil without inverting a soil layer. Chisel plows cause less residue disturbance than moldboard plows and are often used in conservation tillage systems.

Disk Harrows (or Disk) - are implements that uses steel blades to slice through crop residues and soil. Disk blades are mounted in groups or gangs that rotate as they move forward through the soil. Front gangs move soil toward the outside of the disk while rear gangs move soil back toward the center of the disk. A disk can be used for primary or secondary tillage.

| A close-up view of a disk harrow in the field. |  (Source: Deere Photo Library, Vol. 1) |

|---|---|

| A field shot of a tractor and disk harrow at work. |  (Source: Deere Photo Library, Vol. 1) |

|

|

| A tractor and row crop cultivator working in soybeans plated with a conservation tillage system. |

| (Source: Deere Photo Library, Vol. 1.) |

(Source: USDA - National Resources Conservation Service) |

The major environmental concern related to soil preparation is erosion.

Soil erosion is a natural process that occurs when the actions of water

and/or wind cause topsoil to be removed and carried elsewhere.

(Source: USDA-NRCS) |

In many agricultural areas, soil is eroding at a rate of several tons of soil per acre per year or higher. The map shows an estimate of total soil erosion on agricultural areas in 1992. This includes both cropland and set-aside land in the Conservation Reserve Program. Forested and urban land is not included in the map.

The good news is that soil erosion in the U.S. is decreasing. From 1982-1997,

soil erosion declined about 40% in the U.S., due to government conservation

programs, technological advances, and extension education efforts.

Water erosion is caused by the erosive power of raindrops falling on the soil (particularly if the soil is not covered by vegetation or residue) or by surface runoff. Raindrops cause the less severe forms of erosion (know as sheet and interrill erosion). Severe erosion problems such as rill erosion, channel erosion, and gully erosion can result from concentrated overland flow of water.

(Source: USDA-ARS) |

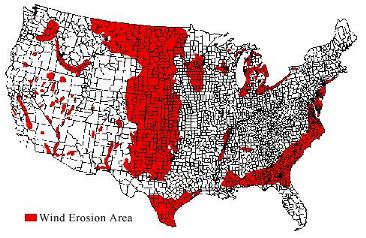

Wind erosion is particularly a problem in windy areas

when the soil is not protected by residue cover. Wind erosion in the United

States is most widespread in the Great Plains states, as can be seen in

the map at right. Wind erosion is a serious problem on cultivated organic

soils, sandy coastal areas, alluvial soils along river bottoms, and other

areas in the United States.

Impacts of soil erosion

Soil erosion has both on-farm impacts (reduction in yield and farm income) and off-farm impacts (contaminated water due to the sediment and associated contamination from nutrients and pesticides carried on the soil particle).

On-farm impacts due to the loss of soil and nutrients include:

When fertile topsoil is lost, nutrients and organic matter needed by crops often are removed along with it. Erosion tends to remove the less dense soil constituents such as organic matter, clays, and silts, which are often the most fertile part of the soil. However, the loss in productivity caused by erosion has not been so evident in many parts of the U.S., since it has been compensated for over the years by improved crop varieties and increased fertilization.

Soils can tolerate a certain amount of erosion without adverse effects on soil quality or long-term productivity, because new soil is constantly formed to replace lost soil. This tolerable level is known as "T" and generally ranges from 3 to 5 tons per acre per year. Goals for reducing soil erosion often use the "T" value as a target, because erosion rates below T should maintain long-term productivity of the soil.

Off-farm impacts occur when the eroded soil is deposited elsewhere, along with nutrients, pesticides or pathogens that may be attached to the soil. The tolerable"T" value described above does not take into consideration the off-farm or downstream impacts. Soil eroded by water has effects such as:

Off-farm impacts of wind erosion are due to the blowing soil, which can reduce seedling survival and growth (seed cover), increase the susceptibility of plants to certain types of stress, contribute to transmission of some plant pathogens, and reduce crop yields. Dust affects air quality, obscures visibility which can cause automobile accidents, clogs machinery, and deposits in road ditches, where it can impact water quality.

(Source: USDA - National Resources Conservation Service) |

| Contour farming and strip cropping is the practice of planting along the slope instead of up-and-down slopes, and planting strips of grass between row crops. |  (Source: USDA - National Resources Conservation Service) |

| Cover crops are crops such as rye that grow in late fall and provide soil cover during winter. By providing a cover to the soil, winter soil erosion from both air and water can be greatly reduced. |  (Source: USDA - National Resources Conservation Service) |

| Grassed waterways protect soil against the erosive forces of concentrated runoff from sloping lands. By collecting and concentrating overland flow, waterways absorb the destructive energy that would otherwise cause channel erosion and gully formation. |  (Source: USDA - National Resources Conservation Service) |

| Terraces are structural practices that can reduce erosion by holding back the water and routing it along a channel at a lower velocity to where it can be safely discharged, usually into a grassed waterway. |  (Source: USDA - National Resources Conservation Service |

| Windbreaks are the best way to protect soil from wind erosion. They can be in the form of rows of shrubs or trees. |  (Source: USDA - National Resources Conservation Service) |

| Windbreaks |  (Source: USDA - National Resources Conservation Service) |

| Grass barriers can prevent wind erosion by slowing the wind. |  (Source: USDA - National Resources Conservation Service) |

| "Living snow fences" prevent wind erosion by slowing the wind. |  (Source: USDA - National Resources Conservation Service) |

Photos courtesy of USDA-Natural Resources Conservation Service, except

for the four pictures for practices controlling wind erosion, from the

ARS Wind Erosion

Unit. ![]()

Maps from USDA-NRCS "State

of the Land." ![]()

Most crops in the U.S. are planted in the spring. The exception is winter wheat, which is planted across the U.S. but concentrated in the central and southern Great Plains and the Pacific Northwest. Winter wheat is planted in the fall, goes into dormancy during the winter, and is harvested for grain the following spring.

The table below shows the "usual planting dates" for six major crops. Planting dates vary by region, following the weather. For simplification, the usual range of planting dates for the top-producing states are shown; if planting dates vary widely, more than one is given. The actual planting dates may begin earlier and extend later, but these are considered the most common.

Source: USDA NASS Agricultural Handbook 628 "Usual

Planting and Harvesting Dates for U.S. Field Crops" ![]()

| Crop | Usual Planting Dates (most active period) in Top-Producing States | Top Producing States | Total Acreage (million acres) |

|---|---|---|---|

| Barley | Apr 7- May 5 (ID); May 2-15 (ND) |

ND, ID |

7 |

| Corn (grain) | April 30-May 18 |

IA, IL |

73 |

| Hay, alfalfa | NA |

CA, SD |

24 |

| Wheat (spring) | May 1-19 | ND | 24 |

| Soybeans | May15-June 5 |

IA, IL, MN |

64 |

| Wheat (winter) | Sept. 20-Oct. 10 |

KS |

52 |

| A grain drill on display at a farm machinery show. |  (Source: Daniel R. Ess, Purdue University) |

| A grain drill planting a crop. |  (Source: farmphoto.com) |

|

| Farm tractor and tillage implement |

| (Source: Daniel R. Ess, Purdue University) |

|

| A twelve-row planter working

in a conventionally-tilled field. |

| (Source: Daniel R. Ess, Purdue University) |

One current controversy related to planting is the choice of seeds. More and more of the seeds planted in the U.S. are genetically modified (GMOs) to make crop production more efficient, to better withstand environmental stresses such as drought, flood, frost, or extreme temperatures, to protect crops against pests such as weeds, insects, or diseases, and to be resistant to herbicides. In 1999, 25% of corn and 54% of soybeans planted in the U.S. were genetically modified.

Environmental concerns related to GMOs include increased pest resistance, development of weed tolerance, and decreased genetic diversity. For example, insects exposed to a genetically engineered crop with the Bt gene (Bt is a natural toxin taken from the Bacillus thuringiensis bacteria, which is toxic to a number of insects) may become more resistant to pesticides. This is a serious concern for organic farmers who use Bt on their crops as an alternative to chemical insecticides. Another environmental concern is that, over time, some weed species could develop a tolerance to herbicides that are applied repeatedly to a crop tolerant to that herbicide. A transgenic crop might cross with another crop or weed, resulting in an undesirable crop or weed species. Others are concerned that reliance on a few genetically modified crops may reduce biological diversity. Also, a lack of genetic diversity in the food supply could increase the risk of catastrophic crop failure and threaten our food security.

To reduce the risk of insect resistance to Bt, a certain percentage of crop acreage on every farm is normally devoted to non-genetically modified variety.

(Source: USDA - National Resources Conservation Service) |

Plant nutrients, which come primarily from chemical fertilizers, manure, and in some cases sewage sludge, are essential for crop production. When applied in proper quantities and at appropriate times, nutrients (especially nitrogen, phosphorus, and potassium) help achieve optimum crop yields. However, improper application of nutrients can cause water quality problems both locally and downstream. Nutrient management is the practice of using nutrients wisely for optimum economic benefit, while minimizing impact on the environment.

Farmers sometimes apply fertilizer soon after the previous year's harvest, since equipment and labor are usually available then. Fertilizer can also be applied in the spring, near the time it is needed by the plant, usually at planting, or as side-dress after the crop has started to grow. In general, the greatest efficiency results when fertilizer is applied at planting time or during the early part of growing season.

Proper timing is most important with nitrogen fertilizer. In some locations, a large part of the nitrogen may be lost if it is applied too long before the crop is planted, particularly if applied the previous fall before soil temperature drops to below 50° F. Phosphorus application is also most efficient when made at or near planting time, especially with soils low in phosphorus. Time of application is less critical with potassium than with nitrogen or phosphorus.

(Source: USDA - National Resources Conservation Service) |

Common nitrogen fertilizers are anhydrous

ammonia (82% nitrogen), urea

(45% nitrogen), urea and ammonium nitrate solutions (28% nitrogen), and

ammonium nitrate (33.5% nitrogen). Manure can be an excellent source of

Nitrogen (N), Phosphorous (P), and Potassium (K) plant nutrients. Every

load of manure is different, however, so manure testing is necessary to

accurately estimate nutrient contents.

|

| Farm tractor and tillage implement |

| (Source: Daniel R. Ess, Purdue University) |

|

|

| A tractor-sprayer-field cultivator

combo that performs tillage and crop chemical application operations simultaneously. |

| (Source: ag-chem, a division of AGCO Corporation.) |

| A self-propelled sprayer broadcasting crop chemicals in the field. |  (Source: ag-chem, a division of AGCO Corporation.) |

| A pull-type sprayer and tractor. |  (Source: ag-chem, a division of AGCO Corporation.) |

|

|

| A twelve-row planter working

in a conventionally-tilled field. |

| (Source: Daniel R. Ess, Purdue University) |

| Spreaders - are implements or vehicles used to apply dry crop chemicals, most often fertilizers. Spreaders typically include a bed, conveyor, and either a set of spinning disks to distribute material over a wide area or a pneumatic system to push material through openings in a boom for distribution on the ground. Spreaders can be mounted on a tractor, pulled by a tractor, self-propelled, or mounted on airplanes. Large self-propelled spreaders that incorporate technologies to vary application rates of multiple dry chemicals within a field can cost more than $250,000. | |

| A self-propelled spreader that uses spinning disks to distribute dry crop chemicals. |  (Source: ag-chem, a division of AGCO Corporation.) |

| A self-propelled spreader that uses a pneumatic system to evenly distribute dry crop chemicals. |  (Source: ag-chem, a division of AGCO Corporation.) |

|

| A tractor-drawn toolbar being

used to inject anhydrous ammonia into the soil. The wagon mounted tank attached to the toolbar supplies ammonia. |

| (Source: Daniel R. Ess, Purdue University) |

Water quality problems can occur when nutrients are added to the soil at a time when they could be removed in surface runoff from rainfall or snow melt at rates exceeding that removed by the crop, or if applied at times that they cannot be utilized by the crop.

When nitrogen or phosphorus are present in lakes or rivers at a high concentration, a condition called "eutrophication" or biological enrichment can occur. High nitrogen from the Mississippi River has been blamed for a hypoxic or "dead" zone in the Gulf of Mexico, where excess algae grow in response to the enriched nutrient solution and few fish can be found. When the algae die, their decomposition consumes enough dissolved oxygen to suffocate fish and other animal life. Sources of nitrogen contributing to the problem include agricultural runoff, sewage treatment plants, atmospheric nitrogen, and other sources.

Excessive nitrate in ground water can present a direct health hazard to very young infants. Ingestion of nitrate (NO3) can bind with hemoglobin in the infant's bloodstream and cause a condition called methemoglobinemia or "blue baby" syndrome. Nitrate does not bind to soil particles and is quite soluble, making it susceptible to leaching into groundwater if not used by the crop.

|

(Source: USDA - National Resources Conservation Service) |

(Source: USDA - National Resources Conservation Service) |

Today, pesticides are used on the vast majority of U.S. cropland. According

to agricultural chemical usage statistics from USDA, herbicides were applied

to 98% of corn acreage and 96% of soybean acreage in 2001.

(Source: USDA - National Resources Conservation Service) |

The label includes information on when the product should be applied. Labels often list the minimum number of days which must pass between the last pesticide application and harvest of crops or grazing by livestock. These are intervals set by EPA to allow time for the pesticide to break down in the environment, preventing residues on food, feed, or animal products.

More and more producers have their pesticides applied by commercial applicators. This practice has many advantages, such as not having to store pesticides on-farm, avoiding having to be certified as pest control applicators, and benefiting from the dealer's record keeping.

|

|

| A tractor-sprayer-field cultivator combo

that performs tillage and crop chemical application operations simultaneously. |

| (Source: ag-chem, a division of AGCO Corporation.) |

| A pull-type sprayer and tractor. |  (Source: ag-chem, a division of AGCO Corporation.) |

| A self-propelled sprayer broadcasting crop chemicals in the field. |  (Source: ag-chem, a division of AGCO Corporation.) |

Aerial application of pesticides has several advantages for the modern agricultural producer. When properly managed, aerial application offers speed of dispersal, accessibility to crops on areas where ground equipment cannot operate, and reasonable cost. In many cases, aerial application also allows more timely applications and, therefore, better utilization of pesticides.

Aerial application programs require good cooperation between the pilot and grower. It must also recognize the potential dangers to people, other crops and the environment.

Limitations on aerial application include weather hazards, fixed obstacles such as radius towers, field size and shape, the distance from the point of application to the landing area, and the danger of contamination of nearby areas due to drift or misapplication. Careless applications can be harmful to the crop, the grower and the applicator.

Source: University

of Kentucky - Applicator Training Manual for Aerial Application of

Pesticides ![]()

A growing practice in many areas of the country is the application of pesticides through irrigation systems, often termed "chemigation." Although there are systems specifically designed for chemigation, in most cases an existing irrigation system is modified to mix the chemical with irrigation water. Fertilizers are generally stored in large tanks located near wells drawing ground water for irrigation. Fertilizers flow from the storage tanks into the irrigation water. Concerns about groundwater contamination from this practice arise from the fact that accidental backflow or siphoning of chemicals into the well can occur when the irrigation pumping system shuts down unexpectedly.

Source: EPA

- Software for Environmental Awareness, Chemigation ![]()

The likelihood of pesticide contamination of groundwater and water wells depends partly on the geologic and hydrologic characteristics that vary from location to location as well as on pesticide characteristics.

Contamination of drinking water wells by pesticides is usually the result of one or more of the following:

Ideally, pesticides should be applied at just the right time to control pests, then degrade into harmless compounds in the soil, air, or water without contaminating the environment. However, this is difficult to attain. Pesticides have the potential to harm the environment by injuring nontarget plants and animals, leaving harmful residues, or moving from the application site into the surrounding environment.

Some pesticides (called accumulative pesticides) can build up in the bodies of animals over time, including humans. These persistent pesticides stay in the environment without change for long periods of time. Pesticides which break down quickly in the environment to form harmless materials area called non-persistent. Most agricultural pesticides used in the U.S. are broken down easily by microorganisms or sunlight.

Pesticides come into contact with nontarget insects and plants through drift, runoff, or spills. Drift to nearby areas may injure fish, birds, other wildlife, and sensitive plants. It can also damage nearby crops, forests, or landscape plantings. Poorly timed applications can kill bees and other pollinators which are working in the area, or beneficial parasites and predators that help control pests naturally .

Pesticides have the potential to contaminate both surface waters (lakes, streams, ponds, rivers) and ground water.

Pesticides can move into surface water through surface runoff, attached to eroding soil particles, or from tile drainage systems. Concerns about pesticide movement in surface runoff include pesticide persistence, time between application and a runoff event, and any management practices in place that reduce surface runoff from the field.

Pesticides can also leach into ground water. The soil type plays an important role in determining the extent to which pesticides leach to ground water. Sandy soils greatly increase the risk of pesticide loss, because they have very limited capacities to adsorb pesticides. In karst areas, pesticides can easily reach ground water through sinkholes. Pesticides may also enter ground water via improperly constructed wells or by back-siphoning into wells while mixing and filling the applicator chemicals. Cases of ground water contamination have also been traced to spills and improper handling of pesticides (such as improper disposal of excess spray and rinsate from cleaning equipment).

The EPA has labeled some commonly used pesticides as having a high probability of moving into ground water when applied to very porous soils. Some pesticides are required to have a statement on their label such as "This product is a chemical that can travel through the soil and contaminate ground water, which may be used as drinking water. This product has been found in ground water because of agricultural use. Users are advised not to apply this product where the water table is close to the surface or where soils are very permeable. Your local Cooperative Extension Service Office can provide further information on the type of soil in your area and the location of ground water".

|

|

(Source: USDA - National Resources Conservation Service) |

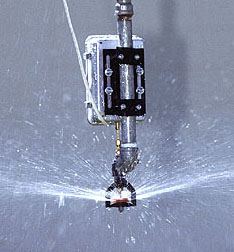

Spray nozzles are an important part of pesticide application equipment. Quality nozzles can reduce pesticide use and reduce environmental pollution.

In row crops, nozzle patterns are directed downward. In citrus and other tree crop applications, it is a common practice to direct half the spray volume laterally toward the upper half of the tree and the rest to the lower half.

Sprayer calibration: Application errors can originate from either incorrect pesticide concentration in the tank, (mixing error) or incorrect sprayer output per unit area (calibration error). The latter may be due to travel speed, nozzle pressure, or the use of improper, defective and worn nozzles. By properly matching sprayer discharge rate, swath width and travel speed, calibration errors can be minimized. Sprayer calibration can be carried out by:

a) determining the amount of the tank mix used to spray a known area;

b) operating the sprayer in a fixed place and measuring the amount of discharged liquid (water) for a specified time; or

c) collecting the nozzle discharge and determining the output for a time period.

The use of high capacity nozzles at low pressures to achieve low-volume application rates, one-sided calibration of the sprayer for two-sided operations and vice versa, calibration at closed pressure settings and intermittent operation of the nozzles can introduce errors in application rates. Sprayers using positive displacement pumps (diaphragm, piston, etc.) have more potential for application error compared to sprayers using centrifugal pumps, particularly at high volume rates.

Source: Florida Cooperative

Extension Service/Institute of Food and Agricultural Sciences/University

of Florida ![]()

|

(Source: USDA - National Resources ) |

(Source: USDA - National Resources Conservation Service) |

Irrigation makes agriculture possible in areas previously unsuitable for intensive crop production. Irrigation transports water to crops to increase yield, keep crops cool under excessive heat conditions and prevent freezing.

Less than 15% of U.S. cropland is irrigated, although irrigation is essential for crop production in some of the most productive areas of the country. For instance, in Arizona, home to some the highest corn yields in the country (208 bushel per acre state average in 2001 compared to 152 for Illinois), much of the crop is under continuous irrigation from planting until harvest.

The need to irrigate is usually driven by the necessity to meet the water needs of the crop from year to year (some areas of the country simply receive too little rainfall during the growing season to support economical crop growth). In other situations, irrigation is viewed as insurance against occasional drought. In areas where rainfall is plentiful in most years, irrigation can bring benefits by reducing risk, meaning that a farmer is better able to control income fluctuation. Other benefits include:

In

1997 there were about 55 million irrigated crop acres in the U.S. Irrigation

is concentrated in certain

areas like central California, Nebraska and the Great Plains, and

the lower Mississippi valley.

In

1997 there were about 55 million irrigated crop acres in the U.S. Irrigation

is concentrated in certain

areas like central California, Nebraska and the Great Plains, and

the lower Mississippi valley.

Although irrigation has always been most common in the West, U.S. irrigated

acreage in the East has also grown from 11 percent of acres in 1969 to

22 percent of acres in 1997.

Irrigation water is obtained from either ground water or surface water. Wells drilled on the farm are a common source of water in many areas, and are usually the only source used in the Great Plains. Offsite sources such as rivers, pipelines, canals operated by irrigation districts and private water companies, are also used, mainly in western states. The percentage of water source used for irrigation varies across the U.S.

Irrigation water is applied throughout the growing season to meet crop needs. Moisture needs depend on the type of crop and its stage of development. In the Eastern Corn Belt, for example, it takes 20-22 inches to produce an optimal corn crop, 18-20 inches for a soybean crop, 12-13 inches for small grain, and 24-26 inches for alfalfa. Irrigation can reduce crop stress if rainfall does not provide this amount of moisture during the growing season.

It is not only total moisture, but also the timing of moisture application (or rain) that is necessary for optimum crop yields. Crops have critical periods during the growing season when soil moisture must be maintained to ensure optimal yields. For corn, the most critical period is from just before tasseling through silking. For small grain, it is from boot to heading stage, for alfalfa, the start of flowering and after cutting, and for pasture, after grazing.

There are four primary types of irrigation:

| With surface irrigation, water flows directly over the surface of the soil. The entire surface can be flooded (most often used for crops that are sown, drilled, or seeded) or the water can be applied through furrows between the rows (for row crops). |  (Source: USDA - National Resources Conservation Service) |

With sprinkler irrigation, water is sprayed through the air from pressurized nozzles, and falls like rain on the crop.

|

(Source: USDA - National Resources Conservation Service) |

|

(Source: USDA - National Resources Conservation Service) |

| Trickle or drip irrigation supplies water directly onto or below the soil surface through "emitters' that control water flow. |  (Source: USDA - National Resources Conservation Service) |

(Source: Modified from Graphic by Leslie Zucker, Ohio State University Extension) |

With subirrigation, the water table is artificially raised either through blocking ditches or by supplying water through the perforated pipes also used for subsurface drainage.

|

Irrigation types can be further distinguished by whether the equipment is permanently installed in one place (stationary system) or whether it is used until the necessary amount of water is applied, then moved to a different area (traveling system). Stationary systems such as permanent spray installations or trickle systems require less labor, but usually cost much more to install. Traveling systems such as center pivot sprinkler irrigation, linear-move, or cable-tow require more labor but less capital expense.

Environmental concerns related to irrigation include depletion of the water source (falling water tables or reduced water levels in streams or reservoirs), soil erosion due to over-application, runoff and leaching of chemicals, and salinization of the soil (salt-buildup) and minerals and nutrients in the irrigation return flow that drains from the irrigated area.

The purpose of agricultural drainage is to remove excess water from the soil in order to enhance crop production. In some soils, the natural drainage processes are sufficient for growth and production of agricultural crops, but in many other soils, artificial drainage is needed for efficient agricultural production.

|

| Impacts of poor drainage -- stunted, yellow plants |

| (Source: Purdue University) |

Surface drainage is the removal of water that collects on the land surface.

Many fields have low spots or depressions where water ponds. Surface drainage

techniques such as land leveling, constructing surface inlets to subsurface

drains, and the construction of shallow ditches or waterways can allow

the water to leave the field rather than causing prolonged wet areas.

|

| Poorly drained area in crop field will damaged yields |

| (Source: Purdue University) |

Today the most common type of "tile" is corrugated plastic tubing with small perforations to allow water entry. When the water table in the soil is higher than the tile, water flows into the tubing, either through holes in the plastic tube or through the small cracks between adjacent clay tiles. This lowers the water table to the depth of the tile over the course of several days.

|

|

| Drain tile outlet to a drainage ditch |

| (Source: Purdue University) |

On average, about two-thirds of annual precipitation is used by crops in the eastern Corn Belt. The rest falls at a time when it does not meet crop needs. Monthly precipitation remains fairly constant throughout the year, while evapotranspiration (a combination of evaporation from soil and transpiration from the crop), is much higher from June to September. From January to May, and from October to December, precipitation is greater than evapotranspiration, creating a water surplus. The surplus results in excess water in the crop root zone and the need for drainage. Drainage is primarily a concern in the periods prior to the growing season (January to April) so that crops can be planted at the optimum time.

(Note: Even in humid areas, crop water needs often exceed precipitation in July, August, and September. Although some of the moisture deficiency is met by stored soil moisture, irrigation can often increase yields.)

Designing and installing a drainage system is a complex process. Every field is unique and usually requires an individual design. Drainage depends on topography, crops that will be grown on the field, and soil type. Every soil type has different properties that affect its drainage. Agronomists and engineers have developed recommendations for drainage depth and spacing in specific soil types based on years of experience and knowledge of soil properties. Drainage contractors use these recommendations to design drainage systems that economically and effectively drain a particular field.

Drainage plows that can be pulled by farm tractors are becoming more popular. But most farmers hire contractors to design and install their tile drainage systems because of the knowledge, skills, and experience needed to install a successful system.

| Trenching machine used by drainage contractors to install subsurface drainage tile (shown in white) |

Source: Purdue University |

| Drainage plow being pulled by farm tractor installing a tileline |  Source: Purdue University |

The major concerns related to drainage are:

Much of the Midwest landscape consisted of wetlands before large-scale drainage began in the 19th century. Although enormous public health and economic benefits have resulted from the draining of these wetlands over the last 150 years, there have also been negative impacts on the environment. Wetlands have an important hydrologic function in regulating water flow and maintaining water quality, as well as providing habitat for water-based wildlife. Recognition of their value has changed the way our society thinks about and protects wetlands.

Drainage improvements today are rarely for the purpose of converting existing wetlands to agricultural production. Improved drainage is usually aimed at making existing agricultural land more productive. Some fields have drain tiles that were installed 100 or more years ago, and are broken or plugged. In many fields, only a few of the wettest spots were originally drained, while the entire field would benefit from improved drainage. More tiles are often added to improve drainage efficiency, with the goal of increasing production.

Drainage has both positive and negative effects on water quality.

In general, less surface runoff, erosion, and phosphorus is lost from land that has good subsurface drainage than from land without drainage improvements or with only surface drainage.

|

| Poor Drainage |

| (Source: Purdue University) |

Pesticides can also flow into subsurface drains, but usually only in very low concentrations. Pesticides move more easily in flow over the soil surface than through the soil, so the highest concentrations of pesticides in tiles are often in fields that have surface inlets into the drains. In fact, subsurface drainage may actually reduce pesticide loss to rivers and streams because it reduces surface runoff

Traditionally, the goals of drainage were to:

(Source: Purdue University) |

Nitrate loss is the biggest water quality concern related to tile drainage. Several new technologies can reduce nitrate loss. Controlled drainage keeps the water table high during the off-season when crops are not growing. The high water table increases the rate of denitrification (a process that converts nitrate to harmless nitrogen gas (N2) as soon as the saturated soil warms up in the spring) and reduces nitrate loss to the environment.

Controlled drainage can be combined with subirrigation to improve yields while protecting water quality. Subirrigation is irrigation back through the subsurface drain tiles. Subirrigation may be economical when fields are relatively level and need to be drained anyway, since additional infrastructure consists mainly of increased numbers of tiles the pumping system. One system being developed in Ohio combines a wetland for water treatment and a pond serving as a reservoir for subirrigation with a drainage system. This system has been shown to increase yields and reduce water quality impacts of drainage, although it is costly.

(Source: USDA - National Resources Conservation Service) |

Harvesting crops involves getting the crop out of the field and transported to market. Most crops are harvested in the fall, except for hay which is cut several times over the course of the summer. Field crops are harvested by machine, while small fruits and other food crops are typically harvested by hand, although in certain cases, they may be harvested by machine. |

(Source: USDA - National Resources Conservation Service) |

| Crop |

Typical harvest period (in eastern

corn belt) |

| Corn - grain | October 7 to November 3 |

| Corn - silage | September 1 to October 15 |

| Soybeans | October 1 to October 20 |

| Wheat (spring) | August 14 to September 1 |

| Wheat (winter) | June 15 to July 15 |

| Hay | Usually 3 cuttings from May 15 to Sept. 30 |

|

| Farm tractor and tillage implement |

| (Source: Daniel R. Ess, Purdue University) |

|

|

| A self-propelled forage harvester

loading chopped corn into a truck on-the-go. |

| (Source: Claas of America.) |

|

| Tractor and pull-type combine operating in a small grain crop. |

| Self-propelled combine equipped with a grain header. |  (Source: Daniel R. Ess, Purdue University) |

| Self-propelled combine equipped with a corn head preparing to harvest corn. |  (Source: Daniel R. Ess, Purdue University) |

| Cotton Harvesters - are self-propelled machines specifically designed to pick (or strip), accumulate, and off-load large quantities of cotton in the field. |

|

| Cotton harvesters at work in the field. | |

| (Source: Deere Photo Library, Vol. 3.) |

|

| A large-capacity grain cart

unloading into a waiting truck. |

| (Source: Daniel R. Ess, Purdue University) |

Balers - are implements used for packaging hay, or straw to permit mechanized handling and transport. The two most common bale formats are large round bales (> 4 feet in diameter) and large rectangular bales (up to 8 feet in length). Large bales can weigh more than 2,000 pounds.

| Large round baler discharging a newly-formed bale of hay. |  (Source: Deere Photo Library, Vol. 3.) |

| Large rectangular baler discharging a newly-formed bale of straw. |  (Source: Class of America.) |

More infomation: Software for Environmental Awareness - interactive software to download.

Properly designed facilities promote storage, handling and disposal practices that enhance worker safety and minimize the risk of point source contamination. An ideal facility incorporates safety features in all aspects of its design and provides:

Back to Storage of Fertilizer and Chemicals

Building a new storage facility just for fertilizer storage may be expensive, but generally it will be safer than trying to modify areas meant for other purposes.

When selecting a site on which to build the facility, two basic criteria should be considered:

When designing and building a new fertilizer or pesticide storage facility, keep in mind a few simple principles of safe storage:

Back to Storage of Fertilizer and Chemicals

Some of the principles for safe fertilizer storage:

If you decide to improve your current storage building, applying the above principles can be expensive. However, compared to the cost of a major accident, fine or lawsuit, storage improvements can be a bargain! If that is not practical, consider how you can protect the fertilizers that you keep on hand.

Sound containers are your first line of defense against a spill or leak. If a container is accidentally ripped open or knocked off a shelf, the spill should be confined to the immediate area and promptly cleaned up. The building should have a solid floor and, for liquid fertilizers, a curb. The containment volume should be large enough to hold the contents of the largest full container.

Ideally, the fertilizer storage area should be separate from other activities. If the building must also serve as a machine shed or as livestock housing, you may find it difficult to meet all the requirements for safe storage.

Back to Storage of Fertilizer and Chemicals

In most states there are two major sets of regulations which impact the design, installation, use and management of aboveground storage tanks (ASTs) for motor fuel and waste oil:

In addition, ASTs may also be subject to state "spill reporting" laws. For instance, Indiana's Spill Reporting Law requires that surface spills and releases of about 25 gallons or more "that enter or threaten the waters of the state" must be reported to the Emergency Response Section of the Indiana Department of Environmental Management within 24 hours, and appropriate corrective action must be initiated immediately. Check for similar laws in other states.

Back to Petroleum Product Storage

Most states have adopted the federal regulations (or a stricter version of them) for underground storage tanks (USTs) greater than 1100 gallons. They may also have regulations for smaller USTs - check to be sure.

State and local UST Regulatory Web sites

Whether regulated or not, all USTs deserve careful management with attention to preventing water pollution, including:

There are many prudent measures to prevent contamination of water supplies, including:Back to Petroleum Product Storage

The federal government has regulated pesticides since the early 1900s.

The use of synthetic pesticides in agriculture is the most widespread method for pest control. "...Farmers spend approximately $4.1 billion on pesticides annually. They justify this high cost by a direct dollar return of from $3 to $5 for every $1 spent on pesticides." (1991 edition of the Handbook of Pest Management in Agriculture.)

Environmental and human health problems related to the use of synthetic pesticides have created an increasing pressure against their use. In recent years, non-chemical alternatives for pest control have been developed and modern pesticides have become safer and more specific. Technical developments of the application equipment have also improved to enable their proper application. However, their proper professional use has not always been transferred satisfactorily to field practice.

Alternative approaches to pest control are used more and more and the concept of integrated pest management where synthetic pesticides are only applied as a last resort is now considered common practice in professional agriculture. The non-chemical alternatives include cultural practices, choice of resistant varieties, creation of an environment favorable for natural enemies of pests, and use of biological products and agents, including beneficial insects.

Likewise, synthetic pesticides have undergone a development process to match today's requirements. They have become less toxic for humans, though not necessarily for the environment, they have become more specific to act as a useful contribution within an IPM concept and they have become more powerful. While 40 years ago pesticides were applied in kilograms or liters of active ingredient per hectare, modern pesticides only require grams or milliliters to achieve the same or better result.

On the other hand, the new pesticides require a more sophisticated technology for a safe, even and efficient application. Modern application equipment (including backpack sprayers) allow a fairly safe and efficient application of pesticides of all kinds. "The design of equipment has impact mostly on the operator and environmental safety preventing unnecessary contamination, accidents, loss and spills and allowing an even distribution of the product." Modern electronics have improved the accuracy of dosing, distribution, and application. The use of global positioning systems (GPS) allows precise tracking of the application. Spray nozzle technology greatly affects spray coverage, which is second in importance only to the selection of the pesticide in determining the success of an application.

Originally, the purpose of pesticide laws and regulations was to protect consumers from fraudulent claims about product performance. The focus now has shifted to the protection of health and the environment, including:

For many years, we have enjoyed the benefits of using pesticides to control weed, insect, fungus, parasitic, and rodent pests. Recently, both the public and the press have increasingly focused on the negative impacts of agricultural, urban industrial, and residential chemicals. However, there are also substantial benefits to society, including:

Back to Agricultural Pesticide Use

Within the last few decades, scientists have learned that some pesticides can leach through the soil and enter the groundwater below. While 50% of the nation depends upon groundwater for drinking water, almost 95% of the households in rural areas use groundwater as their primary source of drinking water. The impact of agricultural chemicals on surface and groundwater quality has become an issue of national importance.

The United States Environmental Protection Agency (EPA) has responsibility under a variety of statutes to protect the quality of the nation's ground water as well as direct responsibility for regulating the availability and use of pesticide products.

Each pesticide product has inherent risks associated with it. Potentially detrimental impacts of pesticides include:

The risk associated with a given pesticide or pesticide product depends on the toxicity of the compound and the probability of exposure.

Source: University of Florida - IFAS

Back to Agricultural Pesticide Use

An LD50 is a standard measurement of acute toxicity that is stated in milligrams (mg) of pesticide per kilogram (kg) of body weight. An LD50 represents the individual dose required to kill 50 percent of a population of test animals (e.g., rats, fish, mice, cockroaches). Because LD50 values are standard measurements, it is possible to compare relative toxicities among pesticides. The lower the LD50 dose, the more toxic the pesticide.

A pesticide with an LD50 value of 10 mg/kg is 10 times more toxic than a pesticide with an LD50 of 100 mg/kg.

The toxicity of a pesticide is related to the mode of entry of the chemical into an organism. Oral LD50 values are obtained when test subjects are fed pesticide-treated feed or water. Dermal LD50 values are obtained when the pesticide is applied to the skin of the animal. Inhalation LD50 values are obtained when the animal breathes the pesticide with a mask. Often the inhalation LD50 is lower (more toxic) than the oral LD50, which is in turn lower (more toxic) than the dermal LD50.

LD50 values are not always given on the pesticide label; rather, the relative toxicity of a pesticide product is reflected by one of three signal words: DANGER, WARNING, or CAUTION. The purpose of signal words is to alert the user to the level of toxicity of the product. The signal word is generally assigned based on the pesticide's inhalation, oral or dermal toxicity, whichever is the most toxic.

Back to Agricultural Pesticide Use

Shortly after the EPA's Groundwater Protection Strategy was issued in August 1984, the Agency initiated an intensive review of existing information and scientific knowledge about the extent of pesticide contamination, its causes and potential health impacts, and statutory authorities and programs available to help address the problem. EPA supports state strategy development through grants under Section 106 of the Clean Water Act as a means for strengthening the capacity of state governments to protect groundwater quality.

Other regulations and programs such as the Safe Drinking Water Act and its amendments, a new Wellhead Protection Program, Clean Water Act, the Federal Insecticide, Fungicide, and Rodenticide Act (FIFRA), and the new Non-point Source Management Program have all been initiated in an attempt to protect the nation's groundwater from contamination by all types of pollutants including pesticides. Since the early 1970s, the EPA's Office of Pesticide Programs has been evaluating the leaching potential of new and existing pesticides.

Because of potential environmental concerns associated with pesticide application, there are two federal laws that regulate pesticide use: FIFRA and FFDCA. Most of the states have also enacted their own pesticide legislation. All pesticide labels contain certain standard information, including the ingredients, directions for proper use, warning statements to protect users, the public, and nontarget species of plants and animals. All statements on the label must be adhered to by all users and sellers. All pesticides must be registered with the EPA to ensure that they will not cause unreasonable adverse effects on the environment.

Certain pesticides are classified as “Restricted-Use” and can only be used by or under the direct supervision of a trained Certified Applicator. Restricted-Use pesticides are those that have a greater chance of causing adverse impacts to humans and the environment. Certification is a way of ensuring that people who apply these restricted-use pesticides possess the knowledge to do so in a safe manner. It is illegal to make restricted use pesticides available to non-certified personnel.

The benefits and risks are periodically reassessed as new scientific information is discovered and to reflect changes in the views of society. This does not mean that decisions of today eventually will be proven wrong. Rather, the balance of benefits and risks is ever-changing because of improved science and the changing expectations of society.

Back to Agricultural Pesticide Use

The importance of formulation type is generally overlooked. The decision to use a formulation for a given application should include an analysis of the following factors:

Individuals such as commercial pest control technicians or farm workers who may not be involved in the selection process but are responsible for the actual application should also be made aware of the type of formulation they are using, its dangers and of the safety measures needed. This choice of formulation type can have an impact on human health and the environment. Inattention to the type of formulation being used could mean the difference between a routine application and one that is the source of environmental contamination - or worse, a serious human exposure.

Back to Agricultural Pesticide Use

Integrated pest management (IPM) is the control strategy of choice for homeowners, growers, and commercial applicators. IPM is an approach to pest management that blends all available management techniques - nonchemical and chemical - into one strategy: Monitor pest problems, use nonchemical pest control, and resort to pesticides only when pest damage exceeds an economic or aesthetic threshold.

Labels and regulations change and new products are introduced routinely. Therefore, the pesticide selection process should be conducted just prior to each growing season.

The selection of a pesticide requires planning and knowledge of the alternatives. Begin by developing a comprehensive list of available pesticides for a specific crop, turf, or home garden pest. Pesticide recommendations for controlling any insect, weed, or disease can be suggested by numerous sources: the Cooperative Extension Service; consultants; agrichemical and urban pesticide dealers; product manufacturers; garden and nursery centers; association newsletters; trade journals; and expert applicators. After developing a pesticide list, the user should obtain labels of all products under consideration so that their strengths and weaknesses can be analyzed on a product profile worksheet. Labels generally are available locally from retail outlets or their suppliers.

Back to Agricultural Pesticide Use

Four factors influence groundwater vulnerability to pesticide contamination:

Options for protecting surface water near application sites include:

Back to Agricultural Pesticide Use

The Kd value is a measure of how tightly the pesticide binds or sticks to soil particles. The greater the Kd value, the less likely a chemical will leach or contribute to runoff. A very high value means it is strongly adsorbed onto soil and organic matter and does not move throughout the soil.

Higher is better. Pesticides are less likely to leach or occur as surface runoff when the Kd is greater than 5.

Back to Agricultural Pesticide Use

Solubility is a measure of how easily a chemical dissolves in water. The lower a chemical's solubility, the less likely it is to move with water through the soil.

Lower is better. Pesticides are less likely to leach when their water solubility is less than 30 parts per million.

Back to Agricultural Pesticide Use

Half-life is a measure of how quickly a chemical breaks down in soil (soil half-life) or water (hydrolysis half-life). The longer a chemical remains in water or soil without breaking down, the more likely it is to leach through the soil.

Shorter is better. Pesticides are less likely to leach when their hydrolysis half-life is less than six months and their soil half-life is less than three weeks.

Back to Agricultural Pesticide Use

Pesticide particle drift and volatilization pose risks to neighbors, field workers, and the environment. Keeping products on the target site increases the effectiveness of pest control while reducing injury to nontarget susceptible plants, domestic animals, and wildlife. The proximity of an application site to sensitive areas such as nursing homes, subdivisions, schools, day-care centers, parks, playgrounds and hospitals is a critical factor requiring extra safety precautions. Misapplication can endanger public health and violate the law.

Two options exist for the applicator who is concerned about drift:

Management decisions that can help prevent off-target movement include:

Products may vary in their ability to move out of the target treatment area. Evaluate each product to determine the best choice for your site requirements.

Back to Agricultural Pesticide Use

Identify the definition that best fits the following terms:

|

|

||

|

|