|

|

|

Pork

Production Phases

The phases of pork production that take place on the farm to produce

hogs ready for market are called: breeding-gestation, farrowing,

nursery and grow-finish.

Back to Pork Main Menu Back to Pork Main Menu

Breeding-Gestation

|

|

Swine production can be logically separated into a number of phases,

beginning with the sow being bred. Historically,

this has been done by placing a number of sows in a pen

with one or more boars. In confinement

buildings, boars are often rotated between sow pens to make sure that

all sows are bred while they were in heat.

Sows in enclosed shelters come into estrous,

3 until 5 days after their pigs are weaned. The estrous period, or standing

heat, is the period when the sow can be bred. Estrous only lasts a

short time, so it is critical that the sow is bred at this time. During

estrous, the sow shows outward signs of being willing to accept the boar,

such as standing still when the producer applies downward pressure on

her back or holding her ears erect. If the sow is not bred during this

period, she normally returns to estrous about 21 days later. These two

periods are known as "first heat breeding" and "second heat breeding".

The non-pregnant sow is considered "unproductive"

during this 3-week period, since she still must be fed and housed. Most

modern operations have sows bred only on first heat. Sows that fail to

breed during this estrous are often sent to market and replaced in the

sow herd by gilts, or young females that are removed from the grow-finish

group of pigs. After breeding, the sow "gestates" her "litter"

for 113 to 116 days before the pigs are born or "farrowed." A good way

to remember gestation length for swine is that it is approximately "3

months, 3 weeks and 3 days".

Back to Top

Farrowing

|

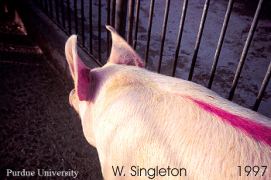

Protecting Baby Pigs

in a Farrowing Crate |

| (Source: Purdue University) |

|

| Pen Farrowing |

| (Source: USDA) |

Just before giving birth, called farrowing, sows are normally moved into

a "farrowing room." Sows typically farrow from eight to twelve piglets,

which as a group are called a litter. Most confinement operations place

the sow in a temperature-controlled environment and usually in a farrowing

pen or crate which restricts her movement to protect her baby pigs. The

baby pigs spend most of their time in a "creep area on one or both sides

of the crate where they have ready access to their mother, but are protected

from crushing when she lies down. A few farrowing operations in the U.S.

use larger pens and provide deep straw bedding on solid floors. While this

is a more natural process for the sow, it involves more labor and often

results in higher crushing losses.

An average sow will raise three to five litters of pigs in her lifetime.

Sows may be culled and sent to market, because of age, health problems,

failure to conceive, or if they are able to raise only a low number of

pigs per litter.

Pigs are born with eight needle-sharp teeth and curly tails. The tips

of the teeth are clipped at birth to prevent injury to the sow's utter

and other piglets and the tail is shortened to prevent tail biting. Piglets

weigh about three pounds at birth and are weaned from the sow at anywhere

from five days to four weeks, with most operations weaning

pigs at two to three weeks.

Back to Top

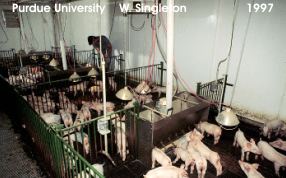

Nursery Pigs

(Source: Purdue University)

|

After weaning, pigs are normally placed in a "nursery" where they are kept

in a temperature-controlled environment, usually on slotted

floors. The floors in a nursery are usually constructed from plastic

or plastic covered steel instead of concrete to provide additional comfort

for the small pigs. Pigs are normally given around three square feet of

space each and provided with ready access to water and feed. Nursery pens

are sometimes elevated, with their slotted floor above the room floor level

8 to 12 inches. This is done to minimize the possibility of cold floor drafts

chilling the young pigs. Immediately after weaning, the temperature in the

nursery may be as much as 85 degrees, and then dropped gradually to about

70 degrees as the pigs grow. Pigs are normally removed from the nursery

at about 6 to 10 weeks of age and placed in a "grow-finishing" building.

Nursery rooms are almost always heated with furnaces and ventilated with

mechanical fans, controlled by a thermostat, in order to keep the pigs warm

and dry throughout the year.

Back to Top

Grow-Finishing

This phase is where pigs are fed as much as they wish to eat until they

reach market weight of 250 to 275 pounds and provided around 8 sq. ft.

of space per pig. Marketing normally occurs at five to six months of age,

depending on genetics and any disease problems encountered. Some gilts

are returned from the grow-finish phase to the sow herd for breeding purposes,

to replace older sows that are culled.

|

|

| Grow-finish Pigs on Concrete Slotted Floor |

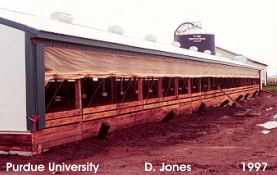

Naturally Ventilated (grow-finish building) |

| (Source: Purdue University) |

|

|

Mechanical Ventilation in

Grow-Finish Building |

| (Source: Purdue University)

|

Animals in a grow-finish operation are larger and produce a great deal of

body heat. Ventilation to keep the animals cool is usually more of a concern

than providing heat in winter. Animals at this age grow best at around 60-70

degrees. In winter, they are protected from winter winds in a moderately

well insulated building. Enough ventilation must be provided to remove moisture

and to provide fresh air for the animals. In summer, large sidewall vents

are opened or large ventilation fans are operated to keep the animals comfortable.

This is referred to, respectively, as naturally

ventilated (air change due to the wind) or mechanically

ventilated (where air is drawn into the buildings through vents due

to a negative pressure created with wall fans that exhaust inside air.

Back to Top

Back to Pork Main Menu Back to Pork Main Menu

|