|

|

|

Milking

Parlors

Cows are milked twice per day on most farms. However, 10% increased milk

production can be obtained by milking the cows 3 times per day, and many

dairy farms are beginning to do so. Some operations even milk a portion

of their cows 4 times per day. Cows housed in tiestall barns are often

milked in their stalls. A number of dairy farms, primarily those whose

owners are members of religious denominations that do not utilize electricity,

still milk cows by hand rather than with

milking equipment. These are not common and usually involve only a few

cows. The milk from such operations does not enter the fresh

milk market and is utilized only for manufacturing purposes. Most

cows milked in tiestall barns are either milked with bucket

milkers or pipeline milking systems. Milking

cows in tiestall barns is extremely labor intensive and requires much

stooping and bending. The desire to reduce this type of labor has led

to many types of milking parlor designs,

in which the milker need not bend to be at the level of the cows udder.

Cows are milked twice per day on most farms. However, 10% increased milk

production can be obtained by milking the cows 3 times per day, and many

dairy farms are beginning to do so. Some operations even milk a portion

of their cows 4 times per day. Cows housed in tiestall barns are often

milked in their stalls. A number of dairy farms, primarily those whose

owners are members of religious denominations that do not utilize electricity,

still milk cows by hand rather than with

milking equipment. These are not common and usually involve only a few

cows. The milk from such operations does not enter the fresh

milk market and is utilized only for manufacturing purposes. Most

cows milked in tiestall barns are either milked with bucket

milkers or pipeline milking systems. Milking

cows in tiestall barns is extremely labor intensive and requires much

stooping and bending. The desire to reduce this type of labor has led

to many types of milking parlor designs,

in which the milker need not bend to be at the level of the cows udder.

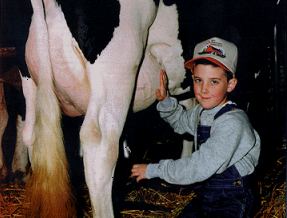

Some cows in the Midwest and

Northeast are milked in Tie Stall Barns.

- Hand Milking (Amish)

- Bucket Milkers

- Pipelines

(Image Source: Genex, CRI) |

|

Walk-through or step-up

parlors are often installed or retrofitted into existing tiestall

barns as a cost effective way of alleviating the demands of the milking

chore. In these parlors cows enter from the rear, step up onto an elevated

platform for milking, and then exit forward through a headgate. Walk through

parlors are inexpensive, but labor demands are still relatively high.

Walk-through Parlor |

|

Step-up Parlor |

|

Image Source: Midwest Plan Service |

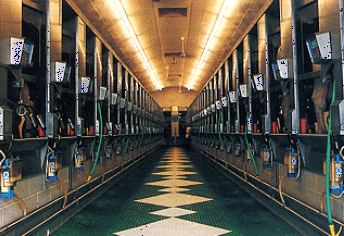

| Herringbone Parlor |

One of the most popular types of parlors is the herringbone,

so named because the cows enter and stand next to each other, but face away

from the operator's pit at an angle. Milkers

attach the milking clusters to the teats from

the side of the cow, and to have better visual contact with the cow's udder

while she is being milked. It is usually easier to keep the milker positioned

properly beneath the cow's udder.

Image Source: Midwest Plan Service |

| Parallel Parlor |

Parallel parlors are similar to the herringbone

parlors except that cows stand perpendicular to the operator pit and the

cows are milked from the rear, between the cow's hind legs. Advantages are

that the cows stand closer together so the worker has to walk less between

cows that are being milked. Disadvantages are that the cow's tail is often

in the way and it may be a long reach for some milkers to reach the cow's

front teats.

|

| Rotary Parlor |

Rotary parlors are gaining in popularity.

Some older styles of rotary parlors were not very efficient or dependable.

New ones, however, have proven to be a viable alternative for large dairy

farms. With the rotary parlor, the platform on which the cows stand moves

around, while the cleaners and milkers stand in one location. Milking cows

is still a demanding task, however, because the cows come by so quickly

that each task must be performed in about 10 to 12 seconds with no break

between cows.

No matter what kind of parlor is used, there are

some key components of milking

procedures that are followed in each. Namely, the cow's teats must

be thoroughly cleaned and dried, the milking equipment must be working

properly and attached properly, and the teats must be disinfected with

an approved teat dip following milking. This

is to prevent possible spread of mastitis from cow to cow. Similarly,

the milk must be handled

properly after it leaves the cow. It must be cooled to under 45 degrees

Fahrenheit within 2 hours of milking. Plate

coolers are often more efficient at cooling milk than bulk

tanks and are used on most farms. Bulk tanks manufactured after January

1, 2000 must be equipped with a recording thermometer so that the temperature

history of the milk can be monitored. A sample of milk from each bulk

tank accompanies the milk truck to the receiving plant. The milk undergoes

a battery of tests to assure that it is safe and of high quality before

it is accepted for processing. Dairy producers must meet specific requirements

for bacteria counts and somatic cells

(white blood cells) in milk; and they are paid a premium for high quality

milk. No added water or antibiotic residues

are allowed, under penalty of losing one's permit to sell milk.

Back

to Dairy Main Menu Back

to Dairy Main Menu

|