Office of Air and Radiation

EPA 402-R-93-003, June 1993PROTOCOLS FOR RADON AND RADON DECAY

PRODUCT MEASUREMENTS IN HOMESSection 3: Discussion of Guidelines Presented in The Home Buyer's and Seller's Guide to Radon

3.1 Introduction 3.2 Options for Real Estate Testing 3.3 Measurement Location 3.4 Measurement Checklist 3.5 Interference-Resistant Testing The unique nature of a real estate transaction, involving multiple parties and financial interests, presents radon measurement issues not encountered in non-real estate testing. EPA's objectives for issuing recommended protocols for radon measurements made for real estate transactions are intended to reduce misunderstanding and protect public health in several ways. First, EPA seeks to provide home buyers, sellers, real estate agents, and testing organizations with a common basis of understanding of the recommended procedures for radon measurements. Second, the widespread implementation of this guidance will produce results that are reliable indicators of the need for mitigation. A significant proportion of radon measurements are conducted as part of real estate transactions, and all aspects of these transactions are carefully scrutinized, so specific guidance from EPA can help to ensure good quality measurements. When the results are interpreted properly and the appropriate remedial action is taken, these protocols will assist the buyer and seller in reducing the risk to the occupants from radon exposure. The availability of a nationally-recognized protocol for measurement and for the interpretation of the measurement results will greatly assist home buyers, sellers, real estate agents, builders, lenders, and radon measurement experts.

These protocols are designed for use in residential buildings, as described in the EPA document, Home Buyer's and Seller's Guide to Radon (EPA 402-R-93-003; U.S. EPA 1993). While that document offers general information on radon and testing, this report presents a more technical description of EPA recommendations, including discussion of guidelines for the interpretation of measurement results. As with all of EPA's policies regarding radon measurements, these guidelines have been developed after review and assistance from the radon measurement community and EPA's Science Advisory Board. Technical information on a variety of radon measurement methods is available in the EPA report titled Indoor Radon and Radon Decay Product Measurement Device Protocols (EPA 520-402-R-92-004; EPA 1992c; these and other EPA publications are available at this web site or from your State or Regional EPA radon office, see Appendix A).

The radon testing guidleines in the Home Buyer's and Seller's Guide to Radon have been developed specifically to deal with the time-sensitive nature of home purchases and sales and the potential for radon device interference. These guidelines are somewhat different from the guidelines in other EPA publications, such as the 1992 Citizen's Guide to Radon (EPA 402-K-92-001; U.S. EPA 1992a), which provide radon testing and reduction information for non-real estate situations.

EPA investigated a variety of options for real estate testing. EPA recommends testing in advance of putting the house on the market. A long-term test, which is conducted for longer than 90 days, is the most representative indication of the annual average radon concentrations in a home. However, for time-sensitive real estatetransactions, the Home Buyer's Guide offers three short-term testing options. Short-term tests are conducted from two days to 90 days, depending on the measurement device. Based on extensive quantitative analyses to evaluate the frequency with which long-term and short-term testing results lead to the same mitigation decision, EPA and its independent Science Advisory Board concluded that short-term tests can be used to assess whether a home should be remediated.

The reliability of each radon measurement made for a real estate transaction, or for any purpose, is highly dependent upon the existence and documentation of an adequate quality assurance program implemented by both the tester and the analysis laboratory. All the parties involved in the real estate transaction depend upon the testers doing their job. This includes ensuring that the measurements are valid via the performance of quality control measurements and activities, and detecting measurement interference. The protocols outlined in this section were developed by EPA for testers and homeowners adhering to the quality assurance practices summarized in Section 4.4 of this report, and in EPA's Indoor Radon and Radon Decay Product Measurement Device Protocols (EPA 520-402-R-92-004; U.S. EPA 1992c).

Three options were determined to be satisfactory and are described here. The availability of three options will allow flexibility on the part of the party purchasing the test. Each of these options will produce results that can be used to determine the need for mitigation.

Both Options 1 and 2 require the use of two measurements made for similar durations. Both measurements should report results in units of pCi/L or both in WL. Similar durations means that the two measurements must be made for a similar time period, with a two-hour grace period. Specific information on measurement methods (listed in Exhibit 3-1) can be found in EPA's Indoor Radon and Radon Decay Product Measurement Device Protocols (EPA 520-402-R-92-004; U.S. EPA 1992c).

Exhibit 3-1

Radon and Radon Decay Product Measurement Method Categories

A

(pCi/L)B

(WL)AC Activated Charcoal Adsorption RP Radon Progeny Sampling Unit (RPSU) AT Alpha Track Detection CW Continuous Working Level Monitoring LS Charcoal Liquid Scintillation CR Continous Radon Monitoring PB Pump-collapsible Bag SC Evacuated Scintillation Cell

(three-day integrating)EL Electret ion Chamber: Long Term ES Electret ion Chamber: Short Term UT Unfiltered Track Detection 3.2 Options for Real Estate Testing

3.2.1 Option 1: Sequential Testing

Sequential tests should be conducted under conditions that are as similar as possible, in the same location, and using similar devices and durations. Both should produce results in the same units (pCi/L or WL). That is, both methods should be from column A or both from column B of Exhibit 3-1. Any EPA-recognized method may be used. In addition, the results of the first test should not be reported prior to making the second measurement; both measurements should be reported at the same time in order to discourage tampering that may occur if the first test is known to be greater than 4 pCi/L or 0.02 WL. Note that measuring with different methods (e.g., with AC and ES) may increase the potential for differences (e.g., measurement bias) between the results. The results of both measurements should be reported, and the average of the two results should be used to determine the need for mitigation. There will be some variation between the two results, which may be caused by the radon levels fluctuating in response to weather or other factors. If the variation is unusually large, it may be due to weather or other effects, but the measurement system should be checked for possible problems.

3.2.2 Option 2: Simultaneous Testing

This option involves the use of two tests, conducted simultaneously and side-by-side, made for similar durations, and producing results in the same units (i.e., both methods should be from column A or both should be from column B of Exhibit 3-1). As with Option 1, using different methods for the two measurements (for example, ES and LS) may increase the potential for differences between the two results. The two test results should be averaged to determine the need for remedial action. The colocated devices should be placed four inches (10 centimeters) apart.

Because radon measurements, like any measurements, usually do not produce exactly the same results, even for simultaneous testing, there will usually be a difference between the two results. EPA offers the following guidance to testers for judging when two simultaneous, side-by-side measurements disagree to such an extent that two additional measurements should be performed.

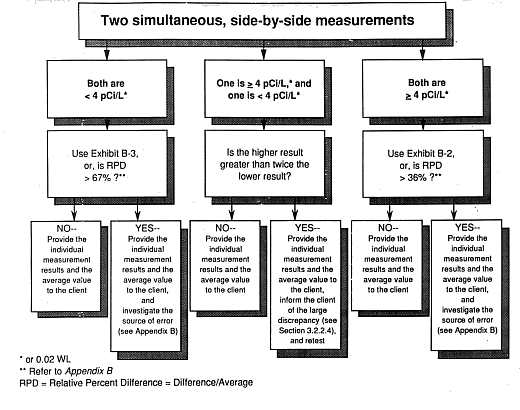

The results of the simultaneous measurements will fall into one of the three categories discussed below and illustrated in Exhibit 3-2.

3.2.2.1 Both Measurement Results Equal To or Greater Than 4 pCi/L (or 0.02 WL)

In this case, the average of the two results will be equal to or greater than 4 pCi/L, or 0.02 WL, and mitigation is recommended. The tester should report both measurement results as well as the average of the two results.

Exhibit 3-2

Deciding on a Retest When Measurements Vary Significantly

3.2.2.2 Both Measurement Results Less Than 4 pCi/L (or 0.02 WL)

In this case, the average of the two measurements will be less than 4 pCi/L, or 0.02 WL, and both measurement results and the average result should be reported to the client.

3.2.2.3 One Measurement Result Greater Than 4 pCi/L (or 0.02 WL), and One Measurement Result Less Than 4 pCi/L (or 0.02 WL)

This is a special situation in which the average of the results is critical. To assist testers in ensuring that the difference between two measurements is small enough so that clients may have confidence in, and understand, the results, EPA offers the following simple guidance.

If the higher result is twice or more the lower result, then the two results are not within a factor of two, and a retest should be conducted. Section 3.2.2.5 provides language for informing the client that a retest is warranted.

If the higher result is less than twice the lower result, then the two results are within a factor of two, and a retest is not necessary. The results of both measurements and the average of the two results should be reported to the client. (See Section 4 for more detailed infomration on quality assurance and quality control procedures.)

3.2.2.4 Precision Recommendations

Measurements near the lower limit of detection (LLD) for the measurement system often have large and varying precision errors, and it is difficult to assign any sort of probability level to very low results.

Simultaneous measurement results that are equal to 4 pCi/L, or 0.02 WL, or greater should, however, exhibit some agreement. An example control chart for the precision that may be expected is shown as Exhibit B-2 in Appendix B, which was constructed using an average relative percent difference of 14 percent. (Relative percent difference is defined as the difference divided by the average.) Using Exhibit B-2, a relative percent difference greater than 36 percent should be observed less than one percent of the time. Based upon this, EPA recommends that any side-by-side, simultaneous measurements with results greater than or equal to 4 pCi/L, or 0.02 WL, and which exhibit a relative percent difference greater than 36 percent, be cause for informing the client that the two results do not show good agreement. However, since both results are greater than 4 pCi/L, or 0.02 WL, EPA recommends mitigation in this case. Testers should investigate the source of the error (see Appendix B).

Results between 2 pCi/L (or 0.01 WL) and 4 pCi/L (or 0.02 WL), should also exhibit some agreement. The level of agreement expected should be based upon the tester's experience with duplicate measurements made with that technique in this range of radon concentrations. An example control chart for the precision that may be expected in this region is shown as Exhibit B-3 in Appendix B, which was constructed using an average relative percent difference of 25 percent. Using this chart, a relative percent difference between duplicates greater than 67 percent should be observed less than one percent of the time. Based upon this, EPA recommends that any side-by-side, simultaneous measurements with results less than 4 pCi/L, or 0.02 WL, and which exhibit a relative percent difference greater than 67 percent, be cause for informing the client that the two results do not show good agreement, but that both are less than 4 pCi/L, or 0.02 WL, and therefore mitigation is not recommended. Testers should investigate the source of the error (see Appendix B).

3.2.2.5 Recommended Language for Informing the Client that a Retest is Warranted

If a retest is warranted (see Section 3.2.2.3), EPA recommends that the testerinform the client that EPA provides guidance for how well two measurements should agree, that the measurements performed fall outside the range, and that a retest should be conducted. A retest should consist of measurements performed according to one of the protocols outlined in Sections 3.2.1, 3.2.2, or 3.2.3.

3.2.3 Option 3: Single Test Option

This option requires an active continuous monitor (method CR or CW) that has the capability to integrate and record a new result at least every four hours. If the monitor cannot integrate over a period of four hours or less, then an additional (secondary) passive or active measurement device must be used. Shorter integration periods and more frequent data logging afford greater ability to detect unusual variations in radon or radon decay product concentrations. The minimum measurement period is 48 hours. The first four hours of data from a continuous monitor may be discarded or incorporated into the result using system correction factors (EPA 520-402-R-92-004; EPA 1992c). There must be at least 44 contiguous hours of usable data to produce a valid average. (The "backing out" of data [i.e., removal of portions imbedded in the two days] to account for weather or other phenoma will invalidate the measurement.) The periodic results should be averaged to produce a result that is reported to the client.

The best way to increase confidence in a radon measurement is to perform a second measurement with another measurement device. The second measurement, which may be made with a passive or active device, can be used simultaneously or sequentially, as discussed in Options 1 and 2 (Sections 3.2.1 and 3.2.2). If the two measurements are performed simultaneously, their results should be evaluated following the guidance in Section 3.2.2. If the two measurements were performed sequentially, it can be expected that the two results will be different. As discussed in Section 3.2.1, the difference between sequential tests may be due to radon levels fluctuating in response to weather or other factors.

However, there are other approaches or features that can be used to increase the confidence of a measurement result obtained using a single active monitor test. These include the use of device self-diagnostic features, and data validation or verification procedures, that could be employed before and/or after the measurement. Examples of such approaches are the use of check sources before and after each measurement, and the use of spectrum readouts. These capabilities are examples, and different technologies may be able to perform other similar self-diagnostic or quality assurance checks. Other features that increase the confidence of a single active test include (but are not limited to) the ability to check air flow rates and voltage meters before and after each measurement. Measurement companies should incorporate such checks into their routine instrument performance checks as part of their standard operating procedures.

Additional features that can increase confidence in measurement results are those that detect measurement interference; these features are discussed in Section 3.5. For example, a continuous monitor that offers a variety of ways to detecttampering may serve to deter, as well as detect, interference with the monitor's operation or with proper closed-building measurement conditions. Potential tampering indicators include the ability of a monitor to record changes in temperature, humidity, or movement of the monitor during the measurement.

Instruments with greater efficiency or sensitivity, or a high signal-to-noise ratio (see Glossary for definitions of these terms), can achieve results with a smaller uncertainty than instruments with low efficiency, poor sensitivity, or low signal-to-noise ratio. The reliability of any type of equipment, however, needs to be established and documented via a complete quality assurance program. This includes routine instrument performance checks prior to and after each measurement, annual calibrations, semi-annual instrument cross-checks, the performance of duplicate measurements in 10 percent of the measurement locations, and frequent background and spiked measurements.

EPA recommends that measurements made for a real estate transaction be performed in the lowest level of the home which is currently suitable for occupancy. This means the lowest level that is currently lived-in, or a lower level that is not currently used (such as a basement, which a buyer could use for living space without renovations). Measurements should be made in a room that is used regularly, such as a living room, playroom, den, or bedroom. This includes a basement that can be used as a recreation room, bedroom, or playroom. This provides the buyer with the option of using a lower level of the home as part of the living area, with the knowledge that it has been tested for radon.

EPA presents the following checklist to help ensure that a radon measurement conducted for a real estate transaction is done properly. The seller (also, you should check first with your State radon contact to confirm what is required to be able to offer radon services in your State) should be able to confirm that all the items in this checklist have been followed. If the tester cannot confirm this, another test should be made.

Before the radon test:

- Notify occupants of the importance of proper testing conditions. Give occupants written instructions or a copy of the EPA Home Buyer's and Seller's Guide to Radon (EPA 402-R-93-003; U.S. EPA 1993), or a State-required alternative, and explain the directions carefully.

- The radon measurement equipment used should be listed by some proficiency organization or listed by your State. Follow the manufacturer's instructions that come with the device.

- If a testing professional conducts the test, he/she should be listed with some national or State-listed program, Check with your State Radon Contact for more information. Under the former National Radon Proficiency Program (RPP), EPA recommended that their photo identification should be provided to the client or homeowner at the time of, or before, the test, and the contractor's identification number should be clearly visible on the test report.

- The test should include method(s) to prevent or detect interference with testing conditions or with the testing device itself.

- Conduct the radon test for minimum of 48 hours. Some devices must be exposed for longer than the 48-hour minimum.

- Check to see if an active radon reduction system is in the house. Before starting a short-term test lasting less than four days, make sure the active system has been operating for at least 24 hours before beginning the test.

- EPA recommends that short-term radon testing, which lasts for no more than a week in length, be done under closed-building conditions. Closed-building conditions means keeping all windows closed, keeping doors closed except for normal entry and exit, and not operating fans or other machines that bring in air from outside. Note that fans that are part of a radon reduction system or small exhaust fans operating for only short periods of time may run during the test.

- When doing short-term testing lasting less than four days, it is important to maintain closed-building conditions for at least 12 hours before the beginning of the test and for the entire test period. Do not operate fans or other machines that bring in air from the outside.

During the radon test:

- Maintain closed-building conditions during the entire time of a short-term test, especially for tests shorter than one week in length.

- Operate the home's heating and cooling systems normally during the test. For tests lasting less than one week, only operate air conditioning units that recirculate interior air.

- Do not disturb the test device at any time during the test.

- If a radon reduction system is in place, make sure the system is working properly and will be in operation during the entire radon test.

After a radon test:

- If a high radon level is confirmed, fix the home. Pages 21 to 23 of EPA's Home Buyer's and Seller's Guide to Radon (EPA 402-R-93-003; U.S. EPA 1993) recommend the next steps that should be taken, such as contacting a qualified radon reduction contractor to lower the home's radon level.

- The radon tester or homeowner should be able to verify or provide documentation asserting that testing conditions were not violated during the testing period.

3.5 Interference-Resistant Testing

EPA strongly encourages the use of radon testing devices with interference-resistant features inherent in, or associated with, the device.

Interference with a radon measurement is defined as the altering of test conditions prior to or during the measurement to either change the radon or decay product concentrations or alter the performance of the measurement equipment. The following discussion reviews some of the types of test interferences and methods of detecting and preventing such interferences.

Test interference typically causes measurement results to be lower than if all proper test conditions were maintained. False low results have been primarily associated with testing during a real estate transaction, although they also happen when the occupants of the dwelling are not properly informed about the necessary test conditions. Test interference can also inadvertently increase measurement results, although the intent is to lower the results.

The current occupant may have an interest in the test results being as low as possible to avoid hindering the sale of the dwelling or incurring the added expense of having to install a mitigation system. The potential for test interference puts the professional radon tester into the position of verifying that the equipment and the required test conditions have been maintained. A measurement result that is below the action guideline may be suspect if the tester cannot verify that the necessary test conditions were maintained.

If the tester arrives at a property and finds windows or doors open, or suspects that closed-building conditions were not maintained for 12 hours prior to arrival, then the tester should extend the test to account for this condition.

3.5.1 Influencing Test Area Concentration

The primary method of temporarily reducing radon levels is to ventilate the test area with outdoor air. Ventilation will slow down radon entry by both reducing negative pressure in the test area and by diluting the reduced radon concentration. Even small openings of a single window in the test area can have a large effect. Ventilating the floors above the test area has significantly less effect, unless the test area is connected with the ventilated room(s) by an operating central air handling system.

Radon decay product levels are sensitive to air movement. As air movement increases, decay products will plate out on walls and other surfaces, including fans, thereby reducing airborne decay product concentrations. Decay products will be further reduced if the fan also includes a filter. Radon levels are, however, not affected by filtering or air movement.

It is also possible to alter concentrations in a tight room if the heating system is operating in an abnormal fashion. Since this may not be the typical operation of the system, it is, in effect, interfering with normal house conditions.

It is important to recognize that test interference can increase radon or decay product levels, despite intent to lower the results.

3.5.2 Equipment Interference

The primary method of interfering with testing equipment is to move the detector to an area of low radon concentration. Other types of interference vary in their ability to influence different types of detectors. For example, interfering with the air sampling mechanisms can maintain the radon concentration at the time of interference, or cause a large decrease in the reported concentration. Similarly, covering a decay product or charcoal detector could cause a large drop in the reported values, while other types of radon detectors would only show a reduced response time to changes in the test area level. In addition, charcoal detectors are sensitive to heat. Some active radon monitors and open face charcoal canisters are also sensitive to high humidity. Any detector that yields a single result could be turned off or sealed in its container or lid during most of its exposure period.

3.5.3 Preventing Interference

EPA recommends that a radon measurement conducted for a real estate transaction be performed using tamper-resistant testing techniques. It is more advantageous for the tester and the client to prevent interference than to simply detect it. Preventing interference can best be accomplished by:

- Educating the client about the necessary test conditions.

- Including in standard documentation for each measurement an agreement (signed by the client) listing the necessary test conditions and the client's agreement not to interfere with the conditions.

This agreement should also include a statement that any test interference that is detected will be documented in the report, and will nullify the test results.

- Informing the client that interference with the test conditions may increase the radon levels.

- Informing the client that the tester is using interference-detecting techniques, and that these allow the detection and documentation of test interference.

3.5.4 Interference-Resistant Detectors

The following is a partial list of common equipment and measures that can serve to prevent and/or detect test interference. There may be other methods available. Equipment that offers a combination of tamper-detecting features also offers a greater chance of detecting interference.

- The ability to integrate and record frequent radon measurements over short intervals (an hour or less) is an important tamper detection feature. Continuous (active) monitors that provide frequent measurements can indicate unusual concentration changes that can be indicators of test interference.

- Measuring other parameters may provide additional indicators of test interference, such as a detector tilt indicator or a continuous recording of pump flow rate.

- A motion indicator can also indicate when the detector was approached or moved.

- A simultaneous, several-day continuous measurement of both radon and decay product concentrations will produce a series of equilibrium ratio values. These values can be inspected for unusual swings or abnormal levels, possibly indicating interference.

- Measurement of CO2 levels can indicate changes in the test area infiltration rate of outdoor air.

- The performance of a grab radon measurement, a grab decay product measurement, or both, before and after a longer-term measurement can offer useful information. For example, the initial and final concentrations and equilibrium ratios can be compared for consistency.

- Frequent temperature readings may help to indicate changes in the test area infiltration rate of outdoor air.

- Humidity (as well as temperature) recordings can be especially helpful in identifying potential unusual changes in test conditions that occur during the test period that might not be detected simply through data logging.

- Instruments that do not allow occupants to view preliminary results (via a visible printer or screen) may reduce occupants' interference.

- Placement indicators can also indicate if a detector has been tampered with or moved. The position of the detector should be noted so that, upon retrieval, any handling of the detector can be indicated by a change in its position. A detector may be hung or placed slightly over the edge of its support to discourage covering it. Passive detectors may be hung or suspended in a radon-permeable bag that uses a unique strap and seal to prevent removing or covering it. Cages can be equipped with a movement indicator to deter handling of the cage or the detector within it.

- Seals can be a practical and effective method for detecting and discouraging test interference. Non-sealable caulks and/or tapes can be used to verify that detectors have not been altered or moved, or that windows or non-primary exterior doors have not been opened.

Unless the detector has other methods for detecting interference, seals should be placed on the lowest operable windows and non-primary exterior doors, as well as between the detector and its support and any other components of the detector that could be tampered with. It may be advisable to place a seal on the furnace control fan switch. It may also be necessary to attach to the caulk seal something fragile that protrudes out, to indicate any handling or covering of the detector.

A number of different products or combination of products can be used for tamper seals. For a seal to be effective, it needs at least the following unique qualities.

- The seal must adhere readily to a multitude of surfaces, and yet be easily removed without marring the surface.

- It needs to be non-resealable or show evidence of disturbance.

- It must be unique enough to prevent easy duplication.

- It should be visible enough to discourage tampering.

The tamper resistance of the seal can be increased by using a caulk over the seal edges or by slicing a large portion of the center of the seal to ensure the seal is broken in case of tampering.

Most paper or plastic tapes and caulks have only some of these qualities. There are, however, a number of seals manufactured specifically for radon testing. It would be advisable to use one of these products and follow the manufacturer's installation recommendations. The best caulking to use as a seal is a removable weatherstripping caulk. This type of caulking adheres readily to most surfaces, yet comes off easily without leaving a mark or being resealable.

Upon retrieval of the detector, the tester should carefully inspect the following:

- That all closed-building conditions are still being maintained;

- Any changes in the detector placement;

- The condition of all seals; and

- Any abnormal variations in any of the measurements made.

This information should be recorded, as described in Section 4.3.5.Table of Contents || Section One || Section Two || Section Four || Appendices || Glossary || References

http://www.epa.gov/iaq/radon/pubs/homprot4.html

Created: July 30, 1999