Cryotech E36®

Liquid Runway Deicer

| Home | Description | Advantages | Customer Profile | Specifications | Application | Properties | Environmental |

| Friction | Compatibility | Advisory | Shipments | MSDS | Guide Specification | Certification | Technical Bulletins |

|

Cryotech E36® Liquid Runway Deicer represents a new generation of

deicers. E36 LRD is a potassium acetate-based runway deicer that was

approved for use in the U.S. in 1992. Because of its high performance and

low environmental effect, the use of E36 has expanded rapidly at airports

and military bases. More and more, airport maintenance personnel are

called upon to keep runways clean and safe without harming the

environment. With legislative and environmental pressures mounting,

airports are changing deicing practices. E36 LRD has set the standard for

runway deicers for years to come.

E36 has been shown to be safe

for use at air force bases utilizing the B-2 Bomber. Per testing by

Northrop Grumman, "All test specimens were unaffected by the exposure of

Cryotech E36 runway anti-icing fluid." E36 has been shown to be safe

for use at air force bases utilizing the B-2 Bomber. Per testing by

Northrop Grumman, "All test specimens were unaffected by the exposure of

Cryotech E36 runway anti-icing fluid."

For a brief summary of E36's benefits, application information, and

product specifications, please see the E36 Fact

Sheet. |

Top

E36 LRD is a high performance,

environmentally responsible alternative to glycol and urea based products.

Experienced users make the following observations about E36 LRD.

High Performance

- E36 LRD has excellent anti-icing and deicing characteristics.

- E36 LRD is faster than other runway deicers.

- E36 LRD is active at low temperatures (-20 deg F and below).

- E36 LRD works longer; requiring fewer applications.

- E36 LRD is less slippery than glycol-based products.

Environmentally Responsible

- E36 LRD does not contain urea or glycol.

- E36 LRD has a lower Biological Oxygen Demand (BOD) than glycol-based

runway deicers.

- E36 LRD biodegrades at low temperatures.

- E36 LRD biodegrades to carbon dioxide and water.

Safe for Aircraft

- E36 LRD is authorized for use at airports by FAA Advisory Circular

150/5200-30A.

- E36 LRD meets material compatibility requirements of AMS 1435.

Top

Potential Customer Profile

Commercial airports and military bases that

are concerned with the quality of storm water run-off and require a high

performance deicer can benefit from E36 LRD. With increased concerns of deicing

chemicals reaching receiving waters, airport managers consider E36 LRD an

important tool in managing environmental issues associated with storm water

run-off. If storm water drains directly from runways or taxiways into a body of

water, NPDES discharge permits require regular monitoring of run-off to

determine certain characteristics, including BOD and contaminants. Because of

low BOD and high performance, E36 LRD can help acheive storm water run-off

objectives. The U.S. EPA recently gave notice to airports to evaluate the use of

potassium acetate (E36 LRD) in lieu of ethylene glycol and/or urea. (Federal Register, 09/29/95)

Top

E36 LRD meets FAA

approved specification SAE AMS 1435, "Fluid, Generic, Deicing/Anti-icing,

Runways and Taxiways".

- Composition:.....50% by weight potassium acetate in water plus corrosion

inhibitors

- Appearance:.....Clear, colorless, mobile liquid, free from matter in

suspension

(May be dyed blue at customer request)

- Density:.....1.28 g/cc (10.68 lb/cf) at 20 deg C (68 deg F)

- pH:.....11.0 +/- 0.5

- Viscosity:.....10 cp maximum at 20 deg C (68 deg F) and 20 cp maximum at 0

deg C (32 deg F)

- Flashpoint:.....Nonflammable

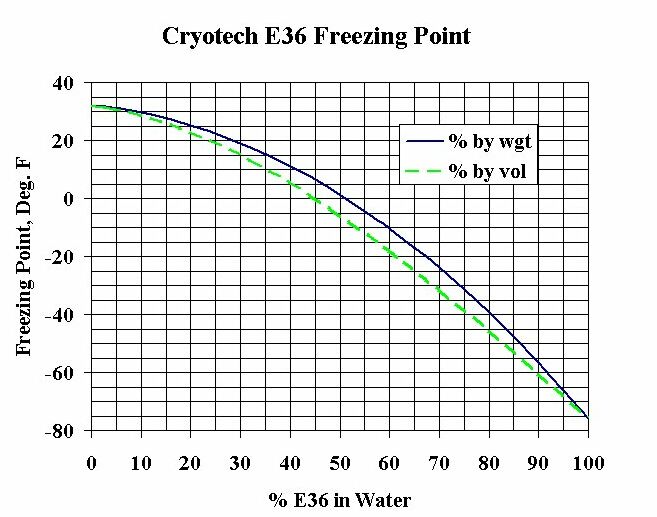

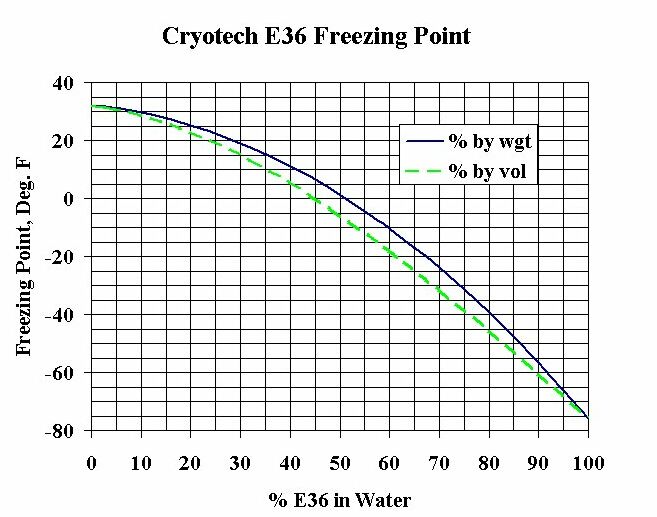

- Freezing Point:.....-60 deg C (-76 deg F)

- Water Miscibility:.....Complete and does not separate in storage

- Specific Gravity:......1.25 - 1.30 at 20 deg C

- Storage:......No special storage required (do not use galvanized

materials)

- Packaging:......55 gallon drum; 265 gallon totes, bulk

Minimum

orders: 4 drums, 1 tote, 4400 gallons bulk

See product MSDS for

more information.

Top

- E36 LRD may be used as an anti-icer or as a deicer. It should be applied

at ambient temperature - not heated. Suggested application rates follow, but

should be used as a starting point, since local conditions will have

significant affect on fluid requirements.

- The most efficient use of E36 LRD is as an anti-icer, pre-treating the

pavement before precipitation actually starts. A high traction film then

exists to prevent adhesion of ice and snow, which can then be mechanically

removed. Uniform coverage is important.

- Experience suggests that E36 LRD, as a deicer, is best applied in bands

(4"-6" [10-15 cm] centers), thereby reducing dilution from melting, allowing

the fluid to penetrate to the surface and break the bonds of ice and snow

prior to mechanical removal.

- Loose snow is not a good medium for movement of E36 LRD. Therefore,

clearing loose snow prior to application, or using high penetration nozzles

will enhance performance.

- E36 LRD penetrates to the surface more readily through hard-packed snow,

thin ice, or ice with natural cracks and flaws. Generally, the longer ice

remains on the surface, the stronger it bonds, and therefore, the more

difficult it is to remove.

- E36 LRD is effective as a prewetting agent.

- ADVISORY - E36 LRD does not separate at low temperatures, as is common

with glycol-based mixtures, and therefore, does not require heated storage.

Separation in storage has also been reported by airports using substitute

potassium acetate deicers.

- Because of E36 LRD's long lasting effect, over application may result in

dry blowing snow sticking to the wetted pavement surface.

- Storage - No special storage required (do not use galvanized materials).

Product Application Rates

The amount of E36 LRD to be applied is

determined by both the surface temperature and the quality and quantity of ice.

Conditions vary, therefore, these application rates are suggested starting

points to be adjusted locally as required.

Prewetting

E36 LRD will speed the effect of solid deicers and abrasives.

E36 LRD is applied at the spreader outlet, typically for prewetting rates of 5%

to 15% by weight of solid material.

- Apply.....1.25 gallons per 100 lbs of deicer or sand (130 g/kg of deicer

or sand)

Anti-icing

E36 LRD is most effective when applied uniformly to pavement

surface before freezing precipitation. Prompt mechanical removal of snow and ice

is necessary to reduce fluid dilution. Re-application may be necessary if snow

and ice begin to bond to the surface.

- Apply.....0.5 gallons/1000 f² (25 g/m²)

Deicing

E36 LRD is an effective deicer when applied in a banded pattern

to penetrate to pavement surface and break the bond of ice and snow. The amount

of deicer needed varies with temperature and thickness of snow or ice, but

should be in the following ranges.

- Apply on thin ice.....1.0 gallon/1000 f² (50 g/m²)

- Apply on 1" (2.5 cm) ice.....3.0 gallons/1000 f² (150 g/m²)

Top

Physical Properties

Top

Tests with E36 LRD show it readily biodegrades at low temperatures and has a

low oxygen demand (BOD) when compared to glycol-based deicers. Toxicity tests

rate E36 LRD "relatively harmless" to aquatic life, the most favorable

classification used by the environmental community. And the fluid contains

neither ammonia nor nitrogen. Therefore, E36 LRD is considered much safer for

the environment than either glycol or urea.

As suggested by the FAA, the following general summary of environmental and

hazard information is provided. Additional detail is available in the MSDS.

Complete test report documentation is available upon request from Cryotech.

Biodegradability

The chemical oxygen demand (COD) of E36 LRD was

determined using EPA Method 410.1

- COD (TOD) = 0.30 gm O2/gm

The biological oxygen demand

(BOD) of E36 LRD was determined using the EPA approved dilution method (Hach).

- BOD20 @ 2 deg C = 0.30 gm O2/gm

- BOD20 @ 20 deg C = 0.30 gm O2/gm

- BOD5 @ 20 deg C = 0.14 gm O2/gm

Aquatic Toxicity

Current EPA methods were used for measuring the acute

and chronic toxicity of E36 LRD. According to the US Fish and Wildlife scale,

material with a LC50 greater than 1000 mg/L is "relatively harmless", which is

the least toxic material classification.

- Fathead minnow 7-day chronic.....LC50 > 1500 mg/L

- Rainbow trout 96-hour acute.....LC50 > 2100 mg/L

- Daphnia magna 48-hour acute.....LC50 > 3000 mg/L

Hazard Information

- Hazardous Waste & Shipping

E36 LRD is not a listed hazardous

waste. The RCRA regulations define hazardous waste in two ways: a listed

hazardous waste or a characteristic hazardous waste. A waste may be considered

hazardous if it exhibits any one of four characteristics - corrosivity,

toxicity, ignitability, or reactivity. A waste is corrosive under RCRA if it

has a pH less than or equal to 2.0 or greater than or equal to 12.5. E36 LRD

is not RCRA corrosive, toxic, ignitable or reactive; therefore, it is not a

characteristic hazardous waste.

- No Hazardous Components

E36 LRD contains no hazardous components

as described by SARA Title III, Section 302. Nor is E36 LRD designated as a

hazardous chemical by the U.S. Department of Transportation. E36 LRD does not

contain nitrates.

- Spill Handling Procedures

E36 LRD is not expected to present

environmental problems. If product should spill, it should be absorbed and the

resulting waste disposed of in a sanitary landfill unless state or local

regulations prohibit such disposal.

- Container and Product Disposal

Based on information available to

Cryotech Deicing Technology, E36 LRD is neither listed as a hazardous waste,

nor does it exhibit any of the characteristics that would cause it to be

classified or disposed of as a RCRA hazardous waste. Empty containers and

product unsuitable for normal deicing operations may be disposed of in a

sanitary landfill unless state or local regulations prohibit such disposal.

Top

Compatibility With Electrical Components

E36

LRD is an ionized solution and is more conductive than water. Users are advised

to take precautions to prevent solutions containing E36 LRD from entering

subsurface conduits and electrical components. E36 is compatible with most

materials, but exceptions occur such as with galvanized metals. Do not use E36

with galvanized materials.

Equipment Considerations

When selecting equipment to transport, store, and apply potassium acetate

runway deicers, the following guidelines should be considered:

Pumps:

- Stainless steel is preferred, but not required.

- Avoid brass and cast aluminum, and cast iron.

- Positive displacement pumps are preferred.

- Avoid large bore, low head (pressure) centrifugal pumps.

Pipes:

- Stainless and carbon steel, PVC, polyethylene, and rubber are okay.

- Avoid galvanized metal piping and fittings.

- Pipe joints should be joined by welding or with compression fittings.

- Avoid threaded joints or use high quality pipe thread sealants.

Seals:

- Butyl rubber, ethylene propylene rubber (EPM, EPDM), isoprene, natural

rubber preferred.

- Nitrile (Buna N), hypalon, neoprene rubber generally acceptable.

- Avoid butadiene, flourocarbon rubber, fluorosilicon, polyacrylate,

polyurethane, SBR rubber (Buna S), silicon rubber.

Tanks:

- Shipping and storage in stainless steel, fiberglass, or polyethylene

containers is preferred.

- Carbon and alloy steel tanks and containers may be used if clean and rust

free.

- Tanks must be strong enough to hold 10.68 pounds per gallon of E36, which

is 28% heavier than water.

Dispensing Equipment

- External surfaces of equipment used to dispense E36 LRD should be

routinely rinsed with warm water to prevent a build-up of the fluid and other

contaminants associated with winter airport operations. A thorough washing

with warm soapy water is recommended as equipment is removed from service

after the deicing season.

- Diluted E36 LRD biodegrades naturally when exposed to air and other

contaminants. This process quickens in warmer temperatures. Frequent rinsings

will prevent any build-up that could result in formations of unsightly

biological growth and superficial staining/corrosion.

- Undiluted E36 LRD kept in closed containers with minimal exposure to air

does not degrade and may be stored indefinitely.

Top

Cryotech E36® LRD is certified to comply with SAE AMS 1435. Fluids meeting

this specification are unique to each manufacturer and may be adversely affected

by mixing with other deicing/anti-icing fluids. Therefore, Cryotech recommends

that E36 LRD not be mixed with other manufacturer's products.

Top

E36 LRD is shipped to customers in the following units:

- Rail Tank Cars.....18,000 gallons (68,000 liters)

- Tank Trucks.....4,400 gallons (16,600 liters)

- Isotanks.....4,000 gallons (15,000 liters)

- Totes.....265 gallons (1,000 liters)

- Drums.....55 gallons (200 liters)

Top

The FAA has established standards for liquid runway deicers. At this writing,

SAE AMS 1435 covers all liquid deicing/anti-icing compounds including E36. This

specification identifies material and environmental properties, and establishes

minimum standards for material compatibility and performance. E36 meets or

exceeds all requirements of this standard as indicated below. Current

certifications are supplied at customer request.

| Top | Home | Description | Advantages | Customer Profile | Specifications | Application | Properties | Environmental |

| Friction | Compatibility | Advisory | Shipments | Guide Specification | Certification | Technical Bulletins |

For information contact:Cryotech Deicing Technology

6103

Orthoway

Fort Madison, Iowa, USA 52627

Tel: (319) 372-6012 or (800)

346-7237

Fax: (319) 372-2662

Email: deicers@cryotech.com

Copyright Cryotech Deicing Technology

1998. |