| Overview: |

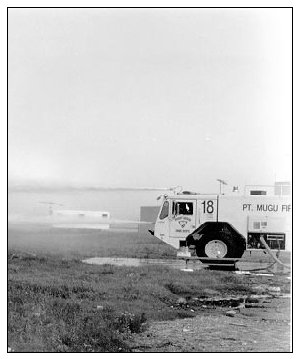

The Aircraft Rescue Fire Fighting

(ARFF) vehicle is currently a main line of defense at shore-based airfield

facilities. These vehicles must be periodically tested, used for training,

and maintained to provide for appropriate operational readiness. The

vehicles use an Aqueous Film Forming Foam (AFFF) for fire suppression.

Despite its wide use and effectiveness for firefighting, AFFF poses an

environmental risk because of its resistance to biodegradation, its

toxicity, and its high Biological Oxygen Demand (BOD) and Chemical Oxygen

Demand (COD). In addition, AFFF has been prohibited for discharge to the

ground and treatment plants at many facilities due to its non-biodegradable

nature, its extreme foaming capacity, and its tendency to upset biological

treatment systems. The combination of these issues has created a conflict

of needs with regard to meeting operational requirements in the protection

of life and property and the stewardship of the environment.

A NoFoam kit has been developed and

demonstrated that replaces AFFF with a benign, biodegradable dye/water

mixture that eliminates the need to release AFFF for operational

maintenance and routine checks. The use of the kit produces a waste stream

that can be assimilated by natural systems or can be treated easily at

treatment plants, thus producing a 100 percent reduction in the problematic AFFF

wastewater stream. (Typically, the amount of AFFF wastewater generated

ranges from 500 to 900 gallons per vehicle per test).

The NoFoam Kit has been demonstrated as a

retrofit to ARFF vehicles models CF4000L (Amertek) and P-19 (Oshkosh). In

the cab of the vehicle, the fire fighter simply pushes and holds a

push-button to activate the kit. The fire fighter then continues through

the normal firefighting discharge procedure. A flow sensor installed in

the kit piping sends electrical signals to the meter in the cab. The

firefighter simply reads the sensor output and quickly determines the

vehicle’s AFFF delivery system performance. By releasing the push-button,

the kit is deactivated and the vehicle is in the ready, firefighting

mission mode.

|

| Compliance Benefit: |

The use of a NoFoam Kit can

help facilities meet material pretreatment standards for discharges of

wastewater into publicly owned treatment works (40 CFR 403) or effluent standards in an

National Pollutant Discharge Elimination System (NPDES) permit (40 CFR 122). In addition, this

treatment process may help facilities meet the requirements of waste

reduction under RCRA (40 CFR 262) and Executive Order 13148.

Under U.S. Naval Fire Protection Program (NAVFAC

Guideline P-1021), tests and training on the

vehicles and structural pumpers are mandated quarterly and annually. In

some cases, based on local airfield requirements, fire chiefs often

conduct daily, weekly, or monthly AFFF system tests in addition to the

mandated requirements. The use of the NoFoam Kit provides an opportunity

to meet or exceed these mandates without environmental

consequence.

The compliance benefits listed here are only

meant to be used as general guidelines and are not meant to be strictly

interpreted. Actual compliance benefits will vary depending on the factors

involved, e.g., the amount of workload

involved.

|

| Materials Compatibility: |

No materials compatibility

issues were identified.

|

| Safety

and Health: |

No safety and health issues

were identified. Consult your local industrial health specialist, your local health and safety personnel,

and the appropriate MSDS prior to implementing this technology.

|

| Benefits: |

- Uses biodegradable and environmentally

benign dye solution or water to test the onboard foam distribution

system.

- Reduces AFFF wastewater normally generated

during firefighting equipment testing, which reduces:

- Groundwater contamination.

- Wastewater treatment plant upsets.

- Hazardous waste management and disposal

requirements.

- Returns quickly to the foam mode after

testing-ready for the fire fighter’s missions.

- Fire Chiefs may perform ARFF vehicle

discharge tests more frequently while staying in environmental

compliance.

- Requires minimal training for firefighters

to operate the kit.

- Equipment is highly cost effective.

|

| Disadvantages: |

None

Identified.

|

| Economic Analysis: |

The NFESC NoFoam Kit is

currently available for ARFF vehicle models CF4000L (Amertek) and P-19

(Oshkosh). The estimated capital cost for each kit is $7,500. The

estimated pay back period is less than two weeks, based on daily foam

distribution system checks. For the purpose of this analysis, one check

consists of eight routine, 5-second system tests (i.e., 5-second

through each nozzles eight times). The minimum pay back period is

estimated at 6 months based on minimal testing frequencies.

Additional cost avoidance savings can be

realized by not using AFFF concentrate in the tests. A 30-second test

consumes approximately 10-20 gallons of AFFF concentrate; thus, a savings

of $70 to $140 per test can be achieved.

Other non-tangible or not readily quantifiable

savings include those realized by elimination of costs associated with

hazardous waste disposal, treatment of the wastewater stream, and/or

downtime of treatment plants due to upsets.

|