| Overview: |

Evaporation is a proven technology

for reducing aqueous wastes. By using active evaporation or heating to

evaporate excess water, hazardous waste rinse water disposal or

wastewater treatment can be minimized.

Evaporator units discussed in this data sheet are gas fired and fully factory assembled. The only potential problem with these systems is the possible mixing of liquid droplets with vapor. This potential problem can be eliminated with the aid of an entrainment separator. The design, process, and safety requirements

for these units are as follows:

- Evaporation rate of 30 to 40 gallons/hour;

- Natural gas-fired (supply available at 8

psig);

- Compatible with existing electrical supply

(120 V);

- Designed for outdoor duty in a marine

environment;

- 304 Stainless steel construction for all

wetted surfaces;

- Water cooled vapor condenser;

- Maximum foot print of 8 feet by 8 feet;

- Fitted with a feed pump;

- Fitted with a concentrated solution removal

pump;

- Automatic fill level control for the

evaporator;

- Unattended operation for at least 8-hours;

- Provisions for the removal of sludge from

the evaporator;

- Automatic gas shutdown when the flame goes

out;

- Condensate receiving tank high level shut

off and alarm; and

- Feed tank low level shut off and alarm.

In addition to these design requirements,

operational options for evaporators include evaporation to the atmosphere

versus evaporation and condensing (closed loop), with no waste emissions.

All evaporator units require operator training. Although all evaporator

units have their own heat source, the humidity of the location can affect

performance. Atmospheric evaporation, in high humidity locations, will

require longer time periods to process a batch.

Evaporation units have the capability to reduce

waste or rinse water by up to 90 percent of the previous volume. This

reduction decreases the quantity of hazardous waste designated for

disposal, and the associated transportation and drum purchase costs for

hazardous waste disposal.

These evaporative systems have been installed

at multiple facilities throughout the Army, Air Force, and the Navy. One

evaporative unit has been in use at Pensacola Naval Air Station, Florida,

since 1992.

|

| Compliance Benefit: |

The use of an evaporator for

aqueous waste reduction may help facilities meet the requirements of waste

reduction under RCRA (40 CFR 262) and Executive Order (EO) 13148.

An evaporator will increase electricity and

water consumption. Under EO 13123, federal

facilities are required to reduce energy consumption and implement water

conservation programs. In addition, the facility will require an air

permit under 40 CFR 70 and 71 or a similar state-only permitting

program for a gas burner and for evaporation to atmosphere.

The compliance benefits listed here are only

meant to be used as general guidelines and are not meant to be strictly

interpreted. Actual compliance benefits will vary depending on the factors

involved, e.g., the amount of workload involved.

|

| Materials Compatibility: |

Because this process only

handles waste, there are no materials compatibility problems. It should be

noted that these systems are for aqueous waste streams and reduce the

amount of water in a waste or rinse stream. If the evaporator waste stream

changes, the evaporation system should be thoroughly cleaned to avoid

cross contamination or chemical reactions.

|

| Safety

and Health: |

Units are equipped with

automatic natural gas shut offs. If the flame goes out, there are low and

high level alarms for the condensate and feed tanks respectively. These

units must be installed in areas with fire-suppression systems, must be

protected from the rain, and should not be allowed to freeze. All of the

proper warning signs such as those concerning hazardous materials and

flammable materials must be posted. Additionally, all appropriate warning

lines must be painted on the floors. All personnel who will work in the

area should be trained prior to operating the evaporator and should be

made aware of the potential hazards associated with the process and the

required personal protective equipment.

Consult your local industrial health

specialist, your local health and safety personnel, and the appropriate

MSDS prior to implementing this technology.

|

| Benefits: |

- Reduces aqueous waste.

- Reduces hazardous waste by up to 90

percent.

- Reduces the cost of hazardous waste

disposal.

- Reduces the cost of drums for hazardous

waste disposal.

- The units can operate unattended.

|

| Disadvantages: |

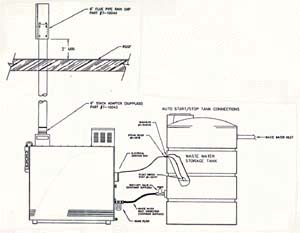

- Requires utility hookups for natural gas,

electricity, and cooling water.

- Requires installation of a concrete pad, and

two 1,500-gallon feed and condensate tanks.

- Requires explosion-proof wall

installation.

- May require an air permit for a gas burner

(new source) and for evaporation to atmosphere.

- All units require operator training.

|

| Economic Analysis: |

This economic analysis compares

the operation of an evaporator versus waste disposal as hazardous. It used an evaporator with capital costs of $83,000. (Lower cost evaporators are available. According to the Pollution Prevention Equipment Program, the capital cost for a rinse water evaporator is $31,000.) For this

evaporator, the annual waste stream processed is 47,000 pounds of

neutralized sulfamic acid contaminated with chrome and 47,000 pounds of

tri-sodium phosphate contaminated with metals. The employment of an

evaporator reduces the quantity of liquid hazardous waste disposal by 90 percent,

resulting in the evaporation of approximately 11,000 gallons of water

annually.

Assumptions:

- Labor to clean the systems is the same for

evaporation (E) or disposal as a hazardous waste (DHW). Labor for

operating the evaporation system: 500 hrs/yr

- 55 gallon drums are required for disposal:

E=20 drums, DHW=220 drums

- Labor rate: $45/hr.

- Utilities for operating evaporation system:

Electrical: 7,600 kwhr, $0.10/kw-hr. Water: 200,000 gallons, $4/1000

gallons Natural gas: $0.08/gallon water evaporated

- Cost of waste disposal: $0.75/lb.

- Annual maintenance costs for the evaporator:

$2,000

- Cost of an empty, clean 55 gallon drum:

$30/drum.

Table 1. Annual Operating Cost

Comparison for Evaporation versus Disposal as Hazardous

Waste

| |

Evaporation |

Disposal as Hazardous

Waste |

| Operational

Costs: |

|

|

| Labor: |

$22,500 |

$0 |

| Material:

|

$600 |

$6,600 |

| Energy:

|

$2,440 |

$0 |

| Waste Disposal:

|

$7,050 |

$70,500 |

| System

Maintenance: |

$2,000 |

$0 |

| Total

Operational Costs: |

$34,590 |

$77,100 |

| Total

Recovered Income: |

$0 |

$0 |

| Net Annual

Cost/Benefit: |

-$34,590 |

-$77,100 |

Economic Analysis Summary:

- Annual Savings for Evaporation:

$42,510

- Capital Cost for Diversion Equipment/Process:

$83,000

- Payback Period for Investment in Equipment/Process: 2

years

Click Here to view an Active

Spreadsheet for this Economic Analysis and Enter Your Own Values. To return from the Active Spreadsheet, click the Back arrow on the Tool Bar.

|

| NSN/MSDS: |

| Product |

NSN |

Unit Size |

Cost |

MSDS* |

| Water evaporator,

paint booth |

4940-01-424-0719 |

ea. |

$21,500 |

|

*There are multiple MSDSs for most

NSNs. The MSDS (if shown above) is only meant to serve as an

example. To return from the MSDS, click the Back arrow on the Tool Bar.

|

| Approving Authority: |

Appropriate authority for making process changes

should always be sought prior to procuring or implementing any of the technologies identified herein.

|