| Overview: |

Solvent distillation, as a means of recycling, is a viable alternative to the single use/disposal of solvents. It is environmentally benign and reduces the amount of solvent purchased and disposed. Solvent distillation is best suited for processing waste solvents that are not excessively contaminated.

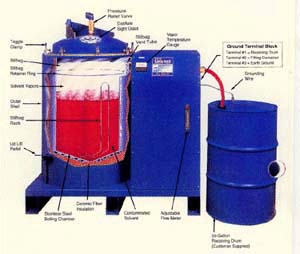

Solvent distillation units process waste solvents in separate, stand-alone batch, on-line batch, or continuous systems. The distillation units heat the waste solvent to its boiling point. The solvent then evaporates, and the solvent vapors are condensed in a separate container. The remaining contaminants in the process chamber are disposed. The basic components of a distillation unit are the process chamber or boiler, encapsulated heaters, an air-cooled condenser, associated piping, and instrumentation. Temperature sensors monitor the temperature and help maintain the required distillation temperature. Disposable vessel liners can be used to provide simple collection and disposal of still bottoms. Vacuum pumps that can distill high-boiling solvents at lower temperatures are also available.

Operating experience at Charleston AFB, South Carolina, has shown recoveries of 90 to 95% for solvents recycled by batch vacuum distillation. Five-gallon batches of methyl ethyl ketone or paint thinner in nominal 5-gallon units typically require 3.5- to 3.75-hour cycles to complete evaporation.

According to Naval Aviation Depot, Cherry Point, North Carolina, solvent distillation rarely brings the designated material back to its original requirement. At NADEP, both CFC-113 and P-D-680 are distilled in separate

units. Generally, distillation processes result in a useable solvent product or a mixture that can be used to serve

an alternate purpose. According to NADEP, an example of this is the solvent distillation for CFC-113 (Freon). NADEP

procures CFC-113 with less than 2 ppm of hydrocarbon contamination. After distillation, the Freon now contains less

than 5 ppm of hydrocarbon contamination that, although still suitable for use, is not as pure as virgin material. In

addition, excessive contamination adds to distillation cost because it generally requires more than one cycle.

|

| Compliance Benefit: |

Use of a solvent distillation unit

will decrease the amount of waste solvent disposed. The decrease in hazardous waste

will help facilities meet the requirements of waste reduction under RCRA, 40 CFR 262,

and may also help facilities reduce their generator status and lessen the applicable

regulatory (i.e., recordkeeping, reporting, inspections, transportation, accumulation

time, emergency prevention and preparedness, and emergency response) requirements under

RCRA, 40 CFR 262. Using a solvent distillation unit may also decrease the amount

of solvents on site below any of the reporting thresholds of SARA Title III for those chemicals

(40 CFR 355, 370, and 372; and Executive Order 13148).

The compliance benefits listed here are only meant to be used as general guidelines

and are not meant to be strictly interpreted. Actual compliance benefits will vary

depending on the factors involved, e.g., the amount of workload involved.

|

| Materials Compatibility: |

Distillation equipment should be constructed of high-alloy

stainless steel to prevent corrosion from degradation of solvents or the heating oil. The alloys also

protect against iron contamination of the recovered solvent. Using a liner adds an extra layer of protection

to the distillation unitís boiling chamber and greatly simplifies cleaning. The liner containing the solvent

residue is simply lifted out of the unit for proper disposal.

|

| Safety and Health: |

Proper design, operation, and maintenance of the distillation equipment are required for its safe use.

Inhalation of solvent vapors can cause irritation to the respiratory tract and mucous membranes. Prolonged exposure may result in damage to the lungs and central nervous system. Contact with the skin can cause dryness, irritation, and possibly dermatitis. Use in well ventilated areas with proper personal protective equipment.

Consult your local industrial health specialist, your local health and safety personnel, and the appropriate MSDS

prior to implementing this technology.

|

| Benefits: |

- Less hazardous waste and hazardous air emissions are generated.

- Reduces hazardous waste disposal costs.

- Provides solvent cost savings.

- Reduces worker exposure to solvent, hazardous waste, and hazardous air emissions.

|

| Disadvantages: |

- Requires trained personnel to perform the recycling process and operate the process equipment.

- Equipment or recycling process may require permits from a local regulatory agency (e.g., Southcoast Air Quality District in California).

|

| Economic Analysis: |

Solvent distillation systems need to be specific to the type of solvent, the contaminants being removed, the batch size or throughput, and the type of cleaning operation. These requirements lead to a wide range of costs. For instance, self-contained, batch-distillation units vary in price from $2,000 to more than $30,000. Costs of the units depend on the size, the materials of construction and the options selected. Capacities typically range from 1- to 250-gallon batches. The following cost estimate is for the use of a 2-gallon capacity solvent distillation-recycling unit. The Freon procurement cost is based on information obtained through FEDLOG:

Assumptions:

- Freon 113 usage (single use of solvent application): 500 gal/yr

- Freon 113 usage (with distillation unit): 100 gal/yr

- Freon procurement cost: $130-140/gal

- Waste solvent (single use of solvent application): 400 gal

- Distillation unit waste sludge (still bottoms): 250 lb/yr

- Waste solvent disposal cost: $1.40/lb

- Still bottoms disposal cost: $1.25/lb

- Labor required for disposal of waste solvent: 1 hr/wk or 52 hr/yr

- Distillation unit electrical requirements: 480 kw-hr/yr

- Electricity: $0.08/kw-hr

- Labor rate: $45/hr

- Total labor requirements recycling unit operation: 2 hr/wk or 104 hr/yr

- Solvent distillation unit cost (installation and training): $3,800

Table 1. Annual Operating Cost Comparison for Solvent Distillation and Solvent Disposal

| |

Solvent Distillation |

Solvent Disposal |

|

Operational Costs:

|

|

|

|

Material:

|

$13,500 |

$67,500 |

|

Labor:

|

$4,680 |

$2,340 |

|

Electricity:

|

$38 |

$0 |

|

Waste Disposal:

|

$313 |

$896 |

|

Total Operational Costs:

|

$18,531 |

$70,736 |

|

Total Recovered Income:

|

$0 |

$0 |

|

Net Annual Cost/Benefit:

|

-$18,531 |

-$70,736 |

Economic Analysis Summary:

- Annual Savings for Solvent Distillation: $52,205

- Capital Cost for Diversion Equipment/Process: $3,800

- Payback Period for Investment in Equipment: < 1 year

Click Here to view an Active Spreadsheet for

this Economic Analysis and Enter Your Own Values. To return from the Active Spreadsheet, click the Back arrow on the Tool Bar.

|