| Overview: |

A solid waste sorting line (SWSL), also known as a dirty material recovery facility (dirty MRF), processes recyclables from a stream of raw solid waste and is typically used in rural areas with no curbside programs and communities that are not actively promoting recycling. A properly designed SWSL will process and recover between five and 45 percent of the incoming material as recyclables. The remainder of the material is used in a waste-to-energy facility, landfilled or otherwise disposed. Materials processed as recyclables include newspaper; steel and aluminum cans; brown, green and clear glass; polyethylene terephthalate (PET) and high-density polyethylene (HDPE) plastic containers. A SWSL serving a small community is typically designed to process less than 200 tons per day of solid waste. A SWSL serving a municipality can process 700 tons per day of solid waste. In many cases, independent private contractors who haul commercial waste operate SWSLs. Rather than hauling the waste directly to the landfill, the trucks stop at an SWSL and recyclable material is extracted. Only the material for which there is no market goes to the landfill.

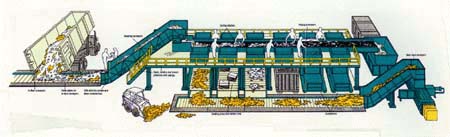

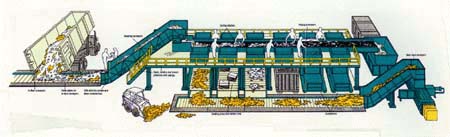

SWSL designs can vary significantly. SWSL sorting systems can be fully automated, partially automated or consist solely of manual sorting systems. A combined system of automated and manual sorting usually begins with automated sizing and sorting and ends with manual sorting. The type of recyclables processed, and anticipated current and future processing rates need to be considered when designing an SWSL. SWSLs typically include a customer vehicle weigh scale and areas for queuing and maneuvering; recyclable shipping areas; vehicle parking; and outdoor storage of recyclables. The main building housing the SWSL will typically include a tipping floor for dumping mixed solid waste, areas for sorting materials and processing recyclables, interim storage of recyclable materials, and warehouse storage for processed recyclables awaiting shipment.

At the tipping floor, a rubber-tired loader spreads the waste out for inspection. At this stage, hazardous items and appliances are recovered. The loader then transports the solid waste onto incline conveyors. These conveyors transport the solid waste to a sorting area, usually located 10 to 20 feet above the ground level. Sorting is conducted at the designated sorting area, and recovered recyclables are dropped into the appropriate segregated collection bins.

In an automated system, the initial sorting operation usually removes bulky or dangerous items followed by waste screening to remove both small grit and aluminum and tin cans. An air classifier, the most common density sorting system used at a SWSL, is used to split the solid waste stream into heavy and light fractions, which allows the other sorting operations to specialize in the most common materials found in the respective fraction. The light fraction includes paper, aluminum cans and plastic, while the heavy fraction includes glass and ferrous materials. Equipment that sorts by chemical composition such as magnets and eddy current separators are commonly used in automated SWSLs.

Manual sorting follows automated sorting. The waste travels down a flat conveyor belt and workers remove the recyclables as they pass by. The conveyor belt for sorting may be as long as 50 to 100 feet to accommodate between five and 20 sorters. The length of the belt depends on the number of types of recyclables and the total amount of each type of recyclable being sorted.

Once the recyclables are separated, they must be processed into materials for sale. Processing typically includes baling for paper, steel cans, and plastic bottles, flattening or densifying for aluminum cans; granulating or perforating for plastic bottles; and crushing for glass bottles. Once processed, the materials are sold directly to specialty recyclers for reuse.

If the residual solid waste can be used in a waste-to-energy facility, additional processing is required. In addition to balers, SWSLs employ other processing equipment including shredders, pelletizers and compactors. A shredder reduces the volume and increases the uniformity of the residual solid waste for use at a waste-to-energy facility. Pelletizers receive shredded waste and extrude it under high pressure to form small pellets. The pellets may then be used as fuel for a furnace or power plant.

Compactors are typically used to process residual solid waste bound for landfills. Compactors are large balers that compress either shredded or un-shredded waste into large bales weighing up to 29 tons. The compactor loads the bales into trailers for transport to a disposal site, which ensures the maximum legal load to reduce hauling costs.

SWSLs operated by municipalities have had a dramatic effect on reducing the reliance on landfills. The use of SWSLs has in many states, been mandated by legislation requiring a significant reduction in landfill disposal. California Assembly Bill 939 requires every city and county in California to reduce its landfill waste stream 25% by 1995 and 50% by the year 2000. Similar mandates are now law in many other states. The employment of SWSLs has greatly assisted municipalities in achieving these goals.

|

| Compliance Benefit: |

Solid waste sorting lines

remove recyclables from a raw solid waste stream, thereby helping facilities

to meet the requirements of Executive Order (EO) 13101, which call for

executive agencies (e.g., Department of Defense) to incorporate waste prevention and recycling

into their daily operations.

Use of a loader may increase fuels on site

which may increase a facility's need to comply with SARA (40 CFR 355, 370)

and EO 13148 reporting requirements as well as spill plan requirements

under 40 CFR 112. In addition, conveyor liners, automated sorting

systems, balers, crushers, shredders and pelletizers will increase electricity

consumption. Under EO 13123, federal facilities are required to reduce

energy consumption.

The compliance benefits listed here are only

meant to be used as general guidelines and are not meant to be strictly

interpreted. Actual compliance benefits will vary depending on the factors

involved, e.g., the amount of workload involved.

|

| Materials Compatibility: |

Material compatibility issues

are specific to the design of the SWSL. Most notably, materials must be inspected when

received at the tipping floor to ensure that materials not compatible to the operation of

the SWSL are not processed. The proper removal and treatment of hazardous materials or

wastes is a necessity.

|

| Safety and Health: |

Safety issues for operators working at an SWSL include the operation of power equipment, as well as eye, ear, respiratory and dermal protection. Therefore proper personal protective equipment including gloves, eye protection, respiratory protection, and hearing protection should be used. Operators should be specifically trained in the use of all machinery. Machinery should not be used if workers are intoxicated or on medication.

Consult your local industrial health specialist, your local health and safety personnel, and the appropriate MSDS prior to implementing this technology.

|

| Benefits: |

- Saves landfill space by diverting recyclable materials.

- Allows municipalities to meet mandated goals for the reduction of landfilled waste.

- Income is generated from the sale of recyclables.

- Cost savings in landfill tipping fees.

- Conserves resources.

|

| Disadvantages: |

|

| Economic Analysis: |

The cost of the equipment and installation of an SWSL varies depending upon the size. A small SWSL non-automated system, including balers will cost on average from $500,000 to $700,000. A large system can cost $1,500,000 or more depending upon the equipment and degree of automation. When conducting an economic analysis for a new SWSL, it is critical that the amounts and types of materials processed, as well as the markets and finished specifications for these materials, be well defined. The market price for recyclables is volatile and as a consequence, predicting the long-term revenue obtained from a SWSL is difficult. Since there are no long-term markets in recyclables, operators of successful SWSLs must research markets on a frequent basis. The volatility of the marketplace makes it necessary for SWSL operators to avoid long-term contracts in order to stay on top of changing commodity prices and to not get locked into a price that has the potential of increasing. The recent high cost of landfill disposal has enhanced the economics of SWSLs.

The economic analysis presented below is for a successful SWSL located in the eastern United States. The facility is processing approximately 1000 tons per month of solid waste

Assumptions:

- Monthly processing rate: 1,000 tons/month of solid waste

- Recovered recyclables: 400 tons/month

- Recovered waste to energy fuel: 200 tons/month

- SWSL labor cost: $100/ton of solid waste

- SWSL energy and maintenance cost: $30/ton of solid waste

- SWSL transportation cost: $20/ton of solid waste

- Recovered recyclable sale cost: $100/ton

- Recovered waste to energy fuel sale cost: $40/ton

- Landfill disposal cost: $25/ton

- Landfill disposal/waste to energy labor cost: $80/ton

- Landfill/waste to energy transportation cost: $25/ton

Table 1. Annual Operating Cost Comparison for Diversion Through Solid Waste Sorting Lines and for Disposal

| |

Diversion

|

Disposal

|

| Operational Costs: |

|

|

| Labor: |

$1,200,000 |

$960,000 |

| Transportation: |

$240,000 |

$300,000 |

| Waste Disposal: |

$120,000 |

$300,000 |

| Energy/ Maintenance: |

$360,000 |

$0 |

| Total Operational Costs: |

$1,920,000 |

$1,560,000 |

| Total Recovered Income: |

$576,000 |

$0 |

| Net Annual Cost/Benefit: |

-$1,344,000 |

-$1,560,000 |

Economic Analysis Summary:

- Annual Savings for New Technology: -$216,000

- Capital Cost for Diversion Equipment/Process: $1,150,000

- Payback Period for Investment in Equipment/Process: N/A

Click Here

to view an Active Spreadsheet for this Economic Analysis and Enter Your

Own Values.

To return from the Active Spreadsheet, click the Back arrow on the Tool Bar.

|

| NSN/MSDS:

|

None identified.

|

| Approving Authority: |

Appropriate authority for making process changes should always

be sought prior to procuring or implementing

any of the technologies identified herein.

|

| Points of Contact: |

For more information

|

| Vendors: |

This is not meant to be a complete

list, as there may be other manufacturers of this type of

equipment.

Mayfran International

P.O. Box 43038

Cleveland, OH 44143

Phone: (440) 461-4100

FAX: (440) 461-5565

Double T Equipment Manufacturing Limited

P.O. Box 3637

Airdrie, AB, T4B 2B8 CANADA

Phone: (403) 948-5618

FAX: (403) 948-4780

|

| |

Norton Environmental

6200 Rockside Woods Blvd.

Independence, OH 44131

Phone: (216) 447-0070

FAX: (216) 447-5028

|

| |

General Kinematics Corporation

777 Lake Zurick Road

Barrington, IL 60010

Phone: (847) 381-2240

FAX: (847) 381-1376

|

| |

Sierra International Machinery, LLC.

620 East Brundage Lane

Bakersfield, CA 93307

Phone: (661) 327-7073

FAX: (661) 322-8759

|

| |

CP Manufacturing, Inc.

1300 Wilson Avenue

National City, CA 91950

Phone: (619) 477-3175 or (800) 462-5311

FAX: (619) 477-2215

|

| Related Links: |

Solid Waste Baler/Conveyors - P2 Equipment Program

Solid Waste Sorting Line

Solid Waste Recycling Trailer

Solid Waste Roll-Off Unit

|

| Sources: |

Mr. Eugene Wang, Naval Facilities Engineering Service Center, March 1999.

Mr. Bob Clinton, Mayfran International, May 1996.

Ms. Shiela Martin, State of California Department of Conservation, Division of Recycling, May 1996.

"The Medina County, Ohio, Central Processing Facility," Waste Age, August 1994.

"Equipping your MRF," World Wastes, February 1993.

"Equipping MRFs," World Wastes, November 1994.

|

| Supplemental: |

Picture of Solid Waste Sorting Line

|