|

|

||||||||||||

| Overview: | Waste pulpers are used to process a variety of solid wastes, primarily portions of the food service waste stream. Waste pulpers grind up organic matter, such as food scraps, cardboard, and paper, with water and then extract most of the moisture to produce a dry, organic pulp. Waste pulpers are available in capacities ranging from 250 to 4,000 lbs./hr. and can reduce the volume of wastes by up to 70 to 85% (depending on the type of pulper used). This can reduce waste, transportation and disposal costs. The dry pulp that is produced is often in a form that can be used for animal feed or composting. Dry pulp can be easily mixed with traditional feed materials, such as urea and corn. Reuse of the pulp product will result in an added reduction of disposal costs. Note: the use of dry pulp requires that the food wastes be segregated from paper and cardboard packaging materials prior to processing.

Waste pulpers are currently employed at numerous facilities across the nation, including educational facilities, restaurants, hotels, health care facilities, corporate dining operations, casinos, cruise ship lines, correctional facilities, manufacturing plants, in-flight kitchens, and municipal/industrial wastewater treatment plants. Although waste pulpers have primarily been used for food service wastes, they also are adaptable to other types of solid wastes, such as biological sludges, pulp and paper mill sludges, textile mill sludges, and cattle and dairy waste solids. Military applications may be appropriate in military base eating facilities and aboard ships. Waste pulpers aboard ships often are used to process food, paper and cardboard wastes prior to disposal. Shipboard waste pulpers use seawater to produce the slurry mixture. They are effective at reducing the volume of wastes and can improve on-board health, safety, and sanitation.

|

||||||||||||||||||||||||||||||

| Compliance Benefit: | A waste pulper processes the

organic components of solid waste for reuse or recycling, thereby helping

facilities to meet the requirements of Executive Order (EO) 13101, which call

for executive agencies (e.g., Department of Defense) to incorporate waste prevention and recycling

into their daily operations. Furthermore, if the resulting dry pulp is used for

composting, the process may also help facilities to meet the environmentally

beneficial landscaping requirements outlined in EO 13148.

A waste pulper, will increase electricity and water consumption. Under EO 13123, federal facilities are required to reduce energy consumption and implement water conservation projects. The compliance benefits listed here are only meant to be used as general guidelines and are not meant to be strictly interpreted. Actual compliance benefits will vary depending on the factors involved, e.g., the amount of workload involved.

|

||||||||||||||||||||||||||||||

| Materials Compatibility: |

No materials compatibility issues were identified.

|

||||||||||||||||||||||||||||||

| Safety and Health: | Food waste collection facilities have the potential

for rodent/pest infestation, foul odor, and unsightly conditions. Although waste pulping systems reduce the

potential for rodent and insect problems (since the wastes are washed with water and then compacted), the owner or

operator should properly maintain the equipment and perform all work in a sanitary environment. Consult your local industrial health specialist, your local health and safety personnel, and the appropriate MSDS prior to implementing this technology.

|

||||||||||||||||||||||||||||||

| Benefits: |

|

||||||||||||||||||||||||||||||

| Disadvantages: |

|

||||||||||||||||||||||||||||||

| Economic Analysis: | The following cost analysis is based on Hobart’s WS-800 pulping unit. This system consists of a pulper, water extractor, valves and an electrical control panel. The capacity of this system is 700 lbs/hr. The pulping system is compared to a 4-hp food waste disposer. The food waste disposer requires the manual separation of approximately 15% of solid waste from the food waste. For the economic analysis presented below, the manual separation required by the disposer system requires an additional 2 hours of labor per day. The pulping system is capable of processing that portion of solid waste without the need for additional labor.

Assumptions:

Table 1. Annual Operating Cost Comparison of Waste Pulper and Food Disposer

Economic Analysis Summary:

Click Here

to view an Active Spreadsheet for this Economic Analysis and Enter

Your Own Values.

|

||||||||||||||||||||||||||||||

| NSN/MSDS: |

*There are multiple MSDSs for most NSNs. The MSDS (if shown) is only meant to serve as an example. To return from the MSDS, click the Back arrow on the Tool Bar. |

||||||||||||||||||||||||||||||

| Approving Authority: | Appropriate authority for making process changes should always

be sought prior to procuring or implementing any of the technologies identified herein.

| ||||||||||||||||||||||||||||||

| Points of Contact: | For more information |

||||||||||||||||||||||||||||||

| Vendors: | This is not meant to be a complete

list, as there may be other manufacturers of this type of

equipment. Hobart Corporation 701 Ridge Avenue Troy, OH 45374-0001 Phone: (937) 332-2000 FAX: (937) 332-2399 |

||||||||||||||||||||||||||||||

| Somat Corporation 855 Fox Chase Coatesville, PA 19320 Phone: (610) 384-7000 FAX: (610) 380-8500 |

|||||||||||||||||||||||||||||||

| Vincent Corporation 2810 5th. Avenue Tampa, FL 33605 Phone: (813) 248-2650 FAX: (813) 247-7557 |

|||||||||||||||||||||||||||||||

| Related Links: |

None | ||||||||||||||||||||||||||||||

| Sources: | Ms. Alma Byrd, Tripler Army Medical Center, March 1999. Mr. Wayne Schenker, Somat Corporation, May 1996. Mr. Jim White, Hobart Corporation, April 1996. Mr. Bill Stoner, Hobart Corporation, June 1996. Ms. Sharon Johnston, Vincent Corporation, May 1996. Ms. Lisa Rabasca, "Waste from Restaurants," Waste Age, March 1993. |

||||||||||||||||||||||||||||||

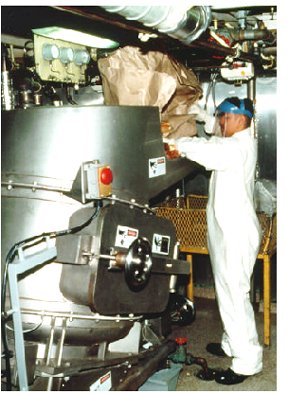

| Supplemental |

Picture of Large Pulpers - Carderock Division

|