To classify used

oil filters as non-hazardous solid waste for disposal purposes or for metal

recycling, filters are crushed or otherwise voided. Waste managers must

contact recycling facilities to ensure drainage techniques and handling

methods are compatible with the recycling facility's requirements. Waste

managers must also contact their state to verify what requirements may apply

beyond the following federal Environmental Protection Agency (EPA) requirements.

Several states have more stringent requirements and do not allow the disposal

of oil filters in landfills.

The EPA used oil filter regulation, published in Title 40 Code of Federal

Regulations (CFR) Section 261.4(b)(13), "Exclusions"

states non-terne plated used oil filters are excluded from

regulation as a hazardous waste provided they are not mixed with

any of the wastes listed in Subpart D, "Lists of Hazardous

Wastes." Specifically, three criteria for the filters must be

met: 1) the filters must not be terne plated; 2) must not be mixed with

other listed hazardous waste; and 3) must be gravity hot-drained. These

criteria are further explained as follows.

Non-Terne Plated

Terne is an alloy of tin and lead formerly used to cover the interior

of oil filters. The lead content may cause terne-plated filters to become toxic.

Mixture Rule

According to 40 CFR 261.3 "definition of hazardous waste,"

a solid waste is exempted from regulation as a hazardous waste if it is

excluded under 40 CFR 261.4(b). The exclusion in 40 CFR 261.4(b)

applies only to hot-drained, non-terne plated used oil filters that have not

been mixed with wastes that are listed in Subpart D of 40 CFR 261.

Gravity Hot-Draining

Non-terne plated used oil filters are exempted from regulation as a hazardous

waste provided they have been gravity hot-drained using one of the following methods:

- Puncturing the filter anti-drain back valve or the filter dome end and hot-draining;

- Hot-draining and crushing;

- Dismantling and hot-draining; or

- Any other equivalent hot-draining method that will remove used oil.

The EPA defines hot draining in the Federal Register, Volume 57, Page 21523

(57 FR 21523) as draining the oil filter near engine operating temperature

and above room temperature. The EPA also recommends a minimum hot-drain time

of 12 hours. The preamble also states, "if an oil filter is picked up by

hand or lifted by machinery and used oil immediately drips or runs from the

filter, the filter should not be considered to be drained." Some states

require a greater amount of oil to be removed from the filters before recycling.

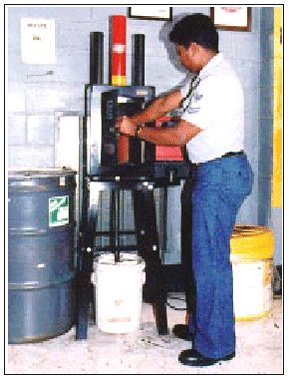

Oil filters are currently collected for recycling at Naval Station San Diego.

The filters are crushed using a commercial filter crusher. All free-flowing oil

is removed and collected during the crushing process. The used filters are

gathered until a minimum of 5,000 pounds is accumulated. The collected filters

are shipped to a local steel mill, where they are used as feed stock in the

company's steel mill operations.

An oil filter crushing operation has also been established at the Puget Sound

Naval Shipyard. This operation has been very successful in minimizing the

hazardous waste disposal costs associated with oil filters.