| Overview: |

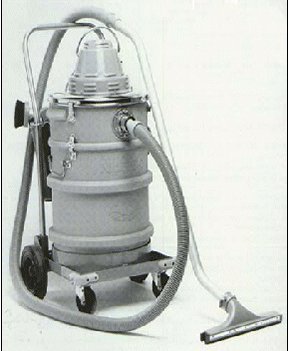

The pneumatically operated

wet and dry vacuum can be used to recover spilled liquids, including fuels, in place of

rags, absorbents, and other spill collection items.

The vacuum operates in a similar fashion to a household vacuum. The vacuumed

liquid is stored in 55-gallon drums or other suitable containers for

recycling, reuse, or proper disposal. In this way, the use of absorbent materials

for spill response is reduced or eliminated. Since absorbent materials that

have been used to address spills are normally heavy in weight, the use of the

pneumatic spill vacuum can help to lower hazardous waste disposal costs.

The pneumatic spill vacuum is in use at several DOD installations, including

Hickam AFB. Non-electric, air operated, explosion-proof vacuums for fuel spills

are also available.

|

| Compliance Benefit: |

Use of a pneumatic spill

vacuum can decrease the amount of hazardous waste generated at a facility

since absorbents do not have to be used. The decrease in hazardous waste

helps facilities meet the requirements of waste reduction under RCRA, 40

CFR 262; the Pollution Prevention Act (42 USC 13101-13109); and Executive

Order (EO) 13148, Greening the Government Through Leadership in

Environmental Management; and may also help facilities reduce their generator

status and lessen the level of regulatory requirements (i.e., recordkeeping,

reporting, inspections, transportation, accumulation time, emergency prevention

and preparedness, emergency response) with which they must comply under RCRA,

40 CFR 262.

The compliance benefits listed here are only meant to be used as general

guidelines and are not meant to be strictly interpreted. Actual compliance

benefits will vary depending on the factors involved, e.g., the amount of

workload involved.

|

| Materials Compatibility: |

The pneumatic spill vacuum is designed to be compatible with a variety of fuels and solvents.

|

| Safety and Health: |

Caution should be exercised

when responding to liquid spills. Proper personal protective equipment

should always be worn, and chemical incompatibility should be assessed. In addition,

flammability and the danger of explosions should be considered. Personnel involved

in spill response activities should also be properly trained in Occupational Safety

and Health Administration (OSHA) requirements, to include: Title 29

CFR 1910.120, "Hazardous Waste Operations and Emergency

Response," and Title 29 CFR 1910.1200, "Hazard Communication."

Consult your local industrial health specialist, your local health and safety

personnel, and the appropriate MSDS prior to implementing this technology.

|

| Benefits: |

- Minimizes the use and cost of absorbents such as pillows, rags, and brooms.

- Minimizes contact personnel may have with liquid spills.

- Decreases disposal costs associated with absorbents.

- Applicable for a variety of liquid spills, lessening the need for specific absorbents for specific chemicals.

- Improves spill response by accelerating spill clean-up.

- If used for small fuel spills, recovered material may be managed as a product (such as fuel that could be burned for energy recovery) instead of being disposed as hazardous waste.

|

| Disadvantages: |

- Requires energy source (air compressor, or an explosion-proof electrical power supply).

- Requires proper disposal of spent activated carbon used in the vacuum.

|

| Economic Analysis: |

According to the Pollution Prevention Equipment Program, the cost for a pneumatic spill vacuum ranges from $1,213 to $5,168. They recover liquids at a rate of 1 gallon/second. The recovered liquids can then be stored in a 55-gallon drum. The following cost elements compare the use of the pneumatic spill vacuum and the use of absorbents.

Assumptions:

- 1,000 gal of fuel spilled/yr.

- Number of 55-gal drums filled/yr: 18.

- Cost of disposing 55-gal drum filled with fuel: $200/55-gal drum (includes transportation cost).

- Cost of disposing one 55-gal drum of spent activated charcoal: $450/55-gal. drum.

- Volume of gasoline for compressor/yr: 100 gal.

- Cost of gasoline: $1.20/gal.

- Labor associated with collecting spills using pneumatic spill vacuum (at 1,000 gal./yr.): 150 hrs for one individual.

- Labor required for spill vacuum maintenance: 10 hrs/yr.

- Absorbents procurement cost: $5,000 (for 1,000 gal.)

- Disposal costs for absorbents/yr: $8,000/yr.

- Labor associated with collecting spills using absorbents (at 1,000 gal/yr): 100 hrs each for three individuals.

- Labor rate: $30/hr.

Table 1. Annual Operating Cost Comparison for Pneumatic Spill Vacuum and Absorbents

| |

Pneumatic Spill Vacuum |

Absorbents |

|

Operational Costs:

|

|

|

Labor:

|

$4,500 |

$9,000 |

Material:

|

$0 |

$5,000 |

Energy:

|

$120 |

$0 |

Waste Disposal:

|

$4,050 |

$8,000 |

System Maintenance:

|

$300 |

$0 |

Total Operational Costs:

|

$8,970 |

$22,000 |

Total Recovered Income:

|

$0 |

$0 |

Net Annual Cost/Benefit:

|

-$8,970 |

-$22,000

|

Economic Analysis Summary:

- Annual Savings for Pneumatic Spill Vacuum: $13,030

- Capital Cost for Diversion Equipment/Process: $5,000

- Payback Period for Investment in Equipment/Process: < 1 year

Click Here to view an Active Spreadsheet for

this Economic Analysis and Enter Your Own Values.

To return from the Active Spreadsheet, click the Back arrow on the Tool Bar.

|