| Overview: |

The FLASHJET® system is a pulsed optical energy

decoating process. It uses a combination of heat generated by a

high-intensity pulsed xenon light and abrasion from a blast medium of

carbon dioxide pellets. The paint is in effect shattered, and the residual

particles are vacuumed and placed in a storage container.

Traditionally,

coating removal activities were performed using chemical or dry abrasive

techniques. Due to the use of toxic solvents, the generation of large

amounts of solid waste, and the environmental, health, and safety concerns

associated with these conventional processes, alternative coating

processes are being investigated. One such alternative is the

FLASHJET® system.

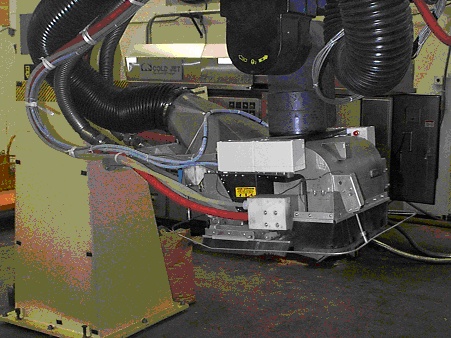

The

FLASHJET® process is a fully automated process that uses

manipulator robotic assembly to strip the coatings from large and small

components. The stripper head contains a xenon flashlamp that produces

pulsed light energy to break the molecular bonds of the coating. Upon the

breaking of the molecular bonds, the coating is changed into a near

gaseous state through a process known as "ablation." Simultaneously, as

the coating is being broken up and the ablation process is occurring, a

dry ice pellet stream is sweeping away the residue while cooling and

cleaning the surface. The paint that is removed is vacuumed away by an

effluent capture system, which consists of high efficiency particulate air

(HEPA) filters and activated charcoal. The effluent capture system

separates the ash from the organic vapors by processing the ash through

HEPA filters and the organic vapor through the activated charcoal. The

only wastes produced by this process are the spent HEPA filters, which are

tested for hazardous waste and disposed accordingly.

The system has a

stripping rate of approximately 270 square feet per hour, and the xenon

lamp is guaranteed for 500,000 flashes, which is directly dependent on the

power level at which the lamp is operated (typically, 1 million flashes

are obtained.)

|

| Compliance Benefit: |

Use of the

FLASHJET® can decrease the amount of hazardous waste generated

at a facility. The decrease in hazardous waste helps facilities meet the

Resource Conservation and Recovery Act (RCRA) waste minimization

requirements applicable to generators of hazardous waste, found at 40

CFR 262. Lower levels of hazardous waste generation may also help

facilities reduce their generator status and lessen the number of

applicable regulatory requirements, such as those covering recordkeeping,

reporting, inspections, transportation, accumulation time, emergency

prevention and preparedness, and emergency response.

In addition to

hazardous waste reduction, the FLASHJET® generates no airborne

contaminants. The elimination of volatile organic compounds (VOCs) and

hazardous air pollutants (HAPs) that are associated with traditional

solvent-based stripping techniques may allow a facility to avoid

regulation under the National Emission Standards for Hazardous Air

Pollutants (NESHAPs) (40 CFR 63). A facility utilizing

FLASHJET® may also be able to avoid related air pollution

regulations at the federal, state, and local levels, including

requirements under the Clean Air Act Title V Operating Permit Program (40

CFR 70 and 71). .

Furthermore, use of

the FLASHJET® may reduce a facility's reporting requirements

under SARA Title III (40 CFR 355, 370, and 372) and EO 13148

and reduce the potential for a release of hazardous substances in reportable

quantities (40 CFR 110 and 302).

The compliance

benefits listed here are only meant to be used as general guidelines and

are not meant to be strictly interpreted. Actual compliance benefits will

vary depending on the factors involved, e.g., the amount of workload

involved.

|

| Safety and Health: |

Caution must be

exercised with the equipment, as high voltages from the xenon lamp are a

potential danger.

Since the process is

used to remove potentially hazardous materials, proper personal protective

equipment (PPE) must be worn and other safety practices must be employed.

The required PPE includes an ultraviolet (UV) curtain, UV goggles, and ear

protection.

Consult your local

industrial health specialist, your local health safety personnel, and the appropriate MSDS

prior to implementing this technology.

|

| Economic Analysis: |

The following cost elements compare the use of a

FLASHJET® process to a plastic media blasting (PMB). Process

variables were provided by the manufacturer (The Boeing Company) and

Warner-Robins Air Force Air Logistics Center, or were estimated based on

production specifications or published data, data from similar analyses,

and best engineering judgement.

Assumptions:

- Parts are from a

CH-53 helicopter, and 100 aircraft units would be stripped annually.

- Labor is $40 per

hour for a PMB system, and $60 per hour for a FLASHJET® system.

- Seam stripping,

also referred to as spot stripping, is assumed to be the same for both

processes.

- Waste associated

with the FLASHJET® process is considered hazardous for this analysis.

The status of this waste is directly associated to the type of paint

being stripped. Therefore, this waste stream can be either hazardous or

non-hazardous.

- Final stripping

results (95-99%) are the same for both processes.

- Breakdown of the

cost categories is shown in the following table.

Table

1. Annual Operating Costs for De-Painting Technologies

|

Cost

Category |

Input Parameter |

PMB Process |

FLASHJET® Process

|

|

Labor

|

Operational |

$391,116 |

$220,916 |

|

|

$12,000 |

$36,000 |

|

|

--- |

$12,810 |

|

|

$4,100 |

$3,075 |

|

Materials |

Media |

$651,147 |

$52,577 |

|

Misc.

material |

$37,660 |

$5,345 |

|

Equipment

upkeep |

--- |

$37,725 |

|

Health &

safety |

Personal

protection |

$1,925 |

$1,200 |

|

Medical

exams |

$100 |

$50 |

|

Utilities

|

Electricity |

$5,950 |

$27,578 |

|

Compressed

air |

$100 |

--- |

|

Waste

Management |

Haz waste

disposal |

$134,117 |

$2,458 |

|

Solid waste

disposal |

$4,395 |

$1,000 |

|

Total |

$1,242,610 |

$400,734 |

Economic Analysis

Summary: A summary of the

financial implications for two scenarios is provided in Table 2. The first

results column addresses replacing a PMB process with a

FLASHJET® system. The next two columns compare the economic

impact associated with installing a coating system at a facility that

currently does not operate a de-painting process. Based on the findings,

the FLASHJET® system is more economical. The 15-year NPV and

IRR, as well as the payback period are also listed in Table 2.

- Annual Savings for

FLASHJET®: $841,876

- Capital Cost for FLASHJET®: $3,271,000, which includes equipment, installation, permit exemption, setup, and training.

- Payback Period for Investment in

Equipment/Process: 5.17 years, using a 15-year analysis and 10%

discount rate. To implement a FLASHJET® system instead of a PMB process at a facility

currently without a de-painting process: 0.95 years, using a 15-year

analysis and 10% discount rate.

Table

2: Financial Implications of Using A FLASHJET® System vs. PMB System

|

Category |

Financial Analysis Results |

|

Replace PMB system |

Install FLASHJET® |

Install PMB system |

|

Investment

Required |

$3,271,000b |

$3,271,000b |

$2,548,680b |

|

Discounted

Payback Period (year) a |

5.17 years |

0.95 years |

N/A |

|

NPV

a |

$3,144,760 |

$5,681,704 |

N/A |

|

IRR

a |

24.8% |

116% |

N/A |

a. This value was calculated with Pollution Prevention

Financial Analysis and Cost Evaluation System (P2/FINANCE). This

software is proprietary and copyrighted by Tellus Institute of

Boston, Massachusetts. A 15-year analysis, and 10% discount rate

were assumed.

b. This number is based on the cost of the equipment,

installation, and other contributing one-time fees related to the

process.

Click Here to

view an Active Spreadsheet for this Economic Analysis and Enter Your Own

Values. To return from the Active Spreadsheet, click the Back

arrow on the Tool Bar.

|