case studies / Environmental credentials of the Olympic experience centre in Sydney Australia

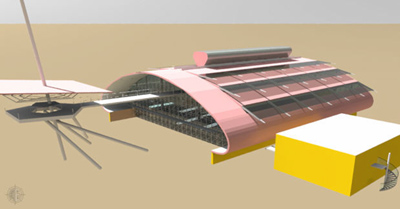

This case study estimates the life cycle environmental impacts of the construction and operation of the proposed Olympic Experience Centre. The pavilion was designed as a low cost environmentally friendly steel building which could be dismantled and relocated after the Olympics.

To provide a fast and user friendly, interactive LCA case study, which allows the user to investigate the life cycle impacts of a range construction, transportation, recycling and utilisation, options.

The Olympic Experience centre was designed to give visitors an insight into the Olympic Games in Sydney 2000, by presenting a film and displaying sporting memorabilia and other information. The building consisted of a 200 seat theatre, a shop, food services and many display areas. It was designed as a low cost, environmentally friendly building, which could be relocated after the Olympic Games. A viewing platform, overlooking the Homebush Bay site was also a feature.

Many ESD principles were included in the design:

The system analysed included the manufacture of all building materials from resources in the ground, building site activities, construction equipment, repairs/maintenance, periodic refurbishment and finally, decommissioning.

The entire life cycle is considered, from resources in ground through to demolition and recycling/landfill of the structure. Landfill emissions are excluded.

Transportation mode and distance are included for each material.

Environmental impacts investigated were resource energy consumption, GGE (greenhouse gas emissions), NOx, SOx, NMVOC (non-methane volatile organic compounds), SPM (suspended particulate matter), and fresh water consumption.

Gross energy (GJ/t), or high heating value (HHV), is used. Feedstock energy is included for all materials except timber.

IPCC weighting factors (global warming potentials) are used in the calculation of greenhouse gas emissions, eg for CH4 and N2O

Australian LCI data. The data are maintained in EMMA (Eco-model for Material and Manufacturing Assessment), BHP's LCA data system. Specific data were supplied by James Grose, the Architect for the project, and associates including structural engineers and project estimators. Information on utilisation was provided by Lincolne Scott.

This study did not require any allocation. Recycled materials have displacement credits allocated based on the displacement of virgin production.

The approach and allocation rules used in the LCI data conform to ISO guidelines for LCA, and attempt to simulate reality as closely as possible.