case studies / Environmental credentials of housing in Australia - Fairweather Homes

This case study estimates the life cycle environmental impacts of the construction and operation of a Fairweather Homes 'Design Series' project home in Melbourne, Australia. The study was conducted over a sixty year period, with the home being demolished after this period. The house was assumed to be occupied by four people for the duration of the study. Appliances and fit out items were replaced every ten years.

To provide a fast and user friendly, interactive LCA case study, which allows the user to investigate the life cycle impacts of a range construction, transportation, recycling and utilisation, options.

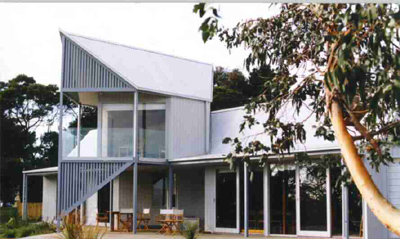

Fairweather Project homes are designed specifically for Melbourne climates and aim for low utilisation energy and minimal impact on the surrounding environment. Fairweather Homes have received the Australian Design Award and The National Energy Award.

Nominal construction is comprises:

Utilisation of appliances can also be selected, with the default being the average consumption of an average Melbourne household. There is also a saved example detailing the energy saving expected with a Fairweather home.

The system analysed included the manufacture of all building materials from resources in the ground, building site activities, construction equipment, repairs/maintenance, periodic refurbishment and finally, decommissioning.

The entire life cycle is considered, from resources in ground through to demolition and recycling/landfill of the structure. Landfill emissions are excluded.

Transportation mode and distance are included for each material.

Environmental impacts investigated were resource energy consumption, GGE (greenhouse gas emissions), NOx, SOx, NMVOC (non-methane volatile organic compounds), SPM (suspended particulate matter), and fresh water consumption.

Gross energy (GJ/t), or high heating value (HHV), is used. Feedstock energy is included for all materials except timber.

Feedstock energy is the specific energy, also termed calorific value, of a material. Traditionally, feedstock energy has not been included in the life cycle energy or embodied energy for timber. Timber is the only material treated in this way. This anomaly results in an artificially low value of embodied energy for timber of approximately 4 GJ/t. Including feedstock energy increases the embodied energy of timber by 10-20 GJ/t, depending on dryness.

This discrepancy, and the increased importance of timber products as a direct energy source (particularly in Europe), is leading to a trend to include feedstock energy for timber products. In this analysis, therefore, both values (ie timber with and without feedstock energy included) were calculated.

IPCC weighting factors (global warming potentials) are used in the calculation of greenhouse gas emissions, eg for CH4 and N2O.

Australian LCI data. The data are maintained in EMMA (Eco-model for Material and Manufacturing Assessment), BHP's LCA data system. Construction data were obtained from Fairweather Homes and detailed plans of the house. Data for utilisation were gathered from various sources, including manufacturers data and the Australian Bureau of Statistics.

This study did not require any allocation. Recycled materials have displacement credits allocated based on the displacement of virgin production.

The approach and allocation rules used in the LCI data conform to ISO guidelines for LCA, and attempt to simulate reality as closely as possible.