Instant acce

The Missouri Dead Animal Law requires that a dead animal carcass be properly disposed of within 24 hours. In Missouri there are five acceptable methods of carcass disposal. They are: rendering, composting, landfilling, incineration and burial. This publication discusses composting as a means of complying with the dead animal law for swine operations. For information on the other methods, refer to MU publication WQ216, Dead Animal Disposal Laws in Missouri.

The composter should be located away from areas of sensitive water quality such as streams, ponds and wells. A location at or near the crest of a hill will eliminate or minimize the amount of surface water approaching the composter from higher areas. If a composter must be located in the lower part of a slope, a diversion terrace should be constructed around the upper side of the composter to keep surface water out.

When locating a composter, consider the farm residence and any nearby neighbor residences that might be affected. While offensive odors are not generated if the composting process is properly managed, the handling of dead swine and compost on a daily basis may not be aesthetically pleasing. Also, consider traffic patterns required in moving dead swine to the composter, moving the required ingredients to the composter and removing finished compost from the composter. The composter site should be well-drained and provide all-weather capability for access roads and work areas.

Composting dead swine requires the addition of a carbon source to ensure proper carbon/nitrogen ratios are present for the composting process. Experience thus far suggests that sawdust an ideal carbon source due to its small particle size, ease of handling, absorbency and high carbon content. Experience using straw as the only carbon source has been less successful, with lower composting temperatures, leaching of fluids from the composting pile and longer composting times required. When sawdust is used as a carbon source, plan to provide about 100 cubic feet of sawdust per 1,000 pounds of carcass to be composted. For farrow-to-finish operations, sawdust requirements are about one-third to one-half cubic yards per sow in the herd on an annual basis. See Table 1 for a summary of compost criteria.

Table 1.

Summary of swine composting design

and management criteria

| Sawdust requirements | One half cubic yard of sawdust per sow in the herd for farrow-to-finish operations (annually) or 100 cubic feet (about 4 cubic yards) of sawdust per 1,000 pound carcass composted. |

| Nitrogen addition | Up to 3 pounds ammonium nitrate per 100 pounds swine carcass as needed, mix with sawdust. |

| Water addition | If sawdust is dry, add water to obtain a damp feel and appearance, up to 1 to 1-1/2 gallons per cubic foot of sawdust. |

| Composter size | 20 cubic feet of primary and secondary bin volume per pound of carcass

composted daily.

Size bins for floor area of 100 to 200 square feet, and depth of 5 to 6 feet. |

| Temperature | 130 to 160 degrees F indicates active composting. |

| Time | Compost three months in primary bins, and an additional three months in secondary bins. |

A precise carbon/nitrogen ratio does not seem to be necessary to obtain good composting, and most composting with sawdust as the carbon source has been done without adding supplemental nitrogen. However, if sawdust is used according to the above recommendations, some supplemental nitrogen would have to be added to obtain the ideal carbon/nitrogen ratio of 25. The addition of about 3 pounds of ammonium nitrate (NH4NO3) in the dry, granular form per 100 pounds of swine carcass will provide the nitrogen necessary to achieve a carbon nitrogen ratio of about 25. The ammonium nitrate should be mixed with the sawdust used to cover the carcass and can be applied by simply "hand-scattering" as carcasses are covered with sawdust. As noted previously, most composting is accomplished without the use of additional nitrogen, but this practice may help in starting up new composting operations and obtaining the desired composting temperatures.

The type of sawdust used in composting can influence the success of the operation. Although a fine or small particle size sawdust is not necessary, wood chips and shavings do not seem to work well due to their larger particle size. Sawdust or wood refuse material derived from bark and/or mulching operations may contain rocks, stones and other foreign material as well as excessively large wood particles, and should not be used for composting.

Most sawdust in Missouri is obtained from sawmills, lumbering and logging operations or cabinet making and furniture making businesses. Such sawdust is generally quite adequate for composting. The moisture content and bulk density of sawdust are important factors in composting. Bulk density is important in estimating the amount of sawdust to use; moisture content, which also affects bulk density, should be in the proper range for composting. Tests on fresh sawdust obtained from seasoned logs or kiln-dried lumber indicate a bulk density of 16 to 20 pounds per cubic foot with a moisture content of 20 to 30 percent. Sawdust stored in a pile tends to gain moisture content. Tests on aged sawdust (more than 5 years old) showed moisture content in the 50 to 70 percent range and bulk density of about 30 pounds per cubic foot. Most of the increase in bulk density is due to the increase in moisture content.

The ideal moisture content in a composting pile is 50 to 60 percent. Swine carcasses have a moisture content near this range, and much sawdust obtained from outside piles may also be near this range. Hence it may not be necessary to adjust moisture content or add water in the composting recipe. However, if the sawdust is exceptionally dry or the composting pile becomes dry due to the internal heat generated, it may be necessary to add water for optimum composting.

The moisture content of sawdust or a composting mixture can be judged somewhat by its appearance and feel. Sawdust that has a damp appearance and feel is probably near the proper moisture content for composting. If it appears wet, or free water can be squeezed out, it should be allowed to dry to a damp condition before being used. Fresh sawdust taken immediately from sawing kiln-dried lumber or seasoned logs will probably be too dry and water will have to be added. Add water as needed to obtain a damp feel and appearance in the sawdust. Very dry sawdust (20 percent moisture) may require the addition of 1 to 1-1/2 gallons of water per cubic foot of sawdust to obtain the proper moisture content. Water should be mixed with the sawdust by sprinkling or spraying as the sawdust is placed on the carcasses. Avoid the over-addition of water, as excessively wet mixtures do not compost properly and may require removal and mixing with dry sawdust to recover the process. "Green" sawdust from fresh-cut, unseasoned logs may have a moisture content as high as 80 percent. Green sawdust may be too wet for optimum composting, and should be allowed to dry somewhat or should be mixed with drier sawdust or finished compost before using. A water line and hydrant installed at the composter will facilitate water addition and general cleanup activities.

Temperature is the best indicator that the composting process is proceeding properly. Temperatures in the composting pile should rise to the 130 to 160 degrees F range, indicating active microbial activity and breakdown of the carcasses.

The composting process requires the proper ingredients to be placed in composting bins in the correct proportions, allowed to compost for a period of time, then moved to a second bin for a secondary composting phase. A minimum of three months composting time is needed in both the primary and secondary phases. It may be necessary to extend this period of time if an unusual number of large carcasses are composted, or if ambient temperatures are low enough to slow the composting process.

In most cases a minimum of three bins will be required, two of which are used for primary composting and the third for secondary composting. In the typical scenario, Bin 1 is filled with three months' death loss, at which time Bin 2 is started. At the end of the second three-month period, Bin 2 is full, and the last carcasses placed in Bin 1 have composted for three months. The contents of Bin 1 are then ready to move to Bin 3 for the secondary composting phase.

After three months of secondary composting, the material can be moved out and applied to land, and the secondary bin is available to receive the contents of Bin 2. Larger operations will require more than the minimum three bins; experience has shown that having extra bins available for storage of fresh sawdust and finished compost is beneficial.

Total bin area and volume requirements depend upon the size of operation and death loss incurred. Actual past death loss data should be used in sizing composters for existing operations. For planning purposes and sizing composters for new operations, see the average death loss data in Table 2. A minimum of 20 cubic feet of volume is needed in both primary and secondary bins per pound of carcass composted daily. Bins are typically filled to a depth of 5 to 6 feet for composting. While bin configuration is not critical, bins are usually laid out as three-sided enclosures. The open side should be wide enough (at least two feet wider than bucket width) so that the bin contents are easily accessible with a front end or skid-steer loader. Square bins offer the greatest opportunity for reduced side effects, (heat loss through walls), although length:width ratios of up to 2:1 are acceptable. Primary and secondary bins should be located close or adjacent to each other (perhaps with a common wall) to facilitate moving compost from bin-to-bin. Excessively large bins should be avoided. Experience has shown that bins with 100 to 200 square feet of surface area work well. See Table 1 for a summary of composter design criteria.

Table 2.

Average annual death loss for swine

in confinement

| Weight range (lbs.) | Average weight (lbs.) | Annual death loss (percent) | Annual death loss per animal space (lbs.) | |

| Sow herd1 | 350-400 | 375 | 6-8 | 21-32 |

| Nursery2 | 13-50 | 32 | 22-26 | 3-13 |

| Finishing | 50-250 | 150 | 10-12 | 5-30 |

| 1Includes all mature animals,

farrowing, gestating, and boars. 2Includes losses in farrowing house prior to weaning. Note: Death losses can vary significantly from the values shown above depending upon genetics, management, environmental conditions, and many other factors. | ||||

Prior to constructing a composter, you must decide whether or not a roof over the composter is preferable. Current Missouri regulations do not require a roof or concrete floor in a swine composter, provided that sawdust is used as the carbon source in the composter. Properly mounded and landscaped sawdust effectively sheds water; leaching of fluids from the bottom of properly managed swine composters does not occur. The use of other carbon sources, such as straw, may require a roof to exclude rainwater and leaching from the pile. Limited experience has shown that use of less absorbent carbon sources like straw may result in leaching and less effective composting even though the composter is roofed.

The primary advantage of an unroofed composter is reduced cost. Advantages of roofed composters include: fewer weather effects on the composting process; worker protection during inclement weather; and a more aesthetically pleasing appearance to match other buildings in the production unit.

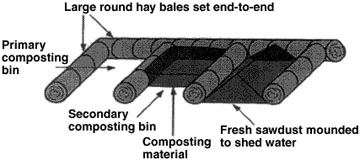

Field experience suggests that composting bins can be constructed using large round bales (5 to 6 feet in diameter) of low-quality hay. Bales are placed end-to-end to form walls for three-sided enclosures or bins. A layout three bales deep and two bales wide as shown in Figure 1 has worked well for swine composters.

Figure 1.

Sample composter layout using hay

bales

Another alternative for the unroofed composter is to use concrete for the bin floor and walls. Although more costly, the concrete is a more durable construction material and is less subject to weathering and mechanical damage during cleaning operations. Also, less room is required than a similar composter using large round bales.

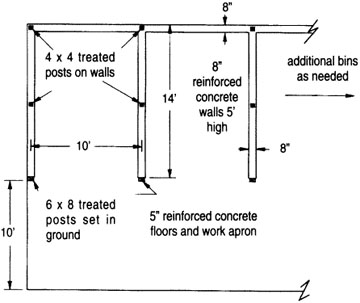

Figure 2 and Figure 3 are schematic drawings of one possible configuration for a roofed composter. This design uses concrete bin walls and floor and pole construction for end walls and roof. The roof overhang and concrete apron in front of the composter minimize rain blowing into the bins and provide a solid work area in front of the composting bins. Many other layouts and materials and could be used in constructing a composter.

Figure 2.

Schematic top view of a roofed

composter with concrete bin walls

Although composting is a simple process, certain equipment is necessary for good management of the operation.

Some type of front-end or skid steer loader is the most necessary piece of equipment in a composting operation. The loader is needed to move carcasses from the production buildings to the composter. Although small carcasses can be deposited and covered in the composter by hand, larger carcasses cannot be adequately managed by hand. The loader provides a means to properly place larger carcasses in the compost pile and adequately cover the carcasses with sawdust of finished compost. The loader is also needed to move compost from primary to secondary bins and can be useful in receiving, storing and piling fresh sawdust from the sawmill. Finally, the loader is necessary for loading out finished compost for field spreading.

A probe-type thermometer will aid in monitoring the compost to determine if it is composting properly. Dial-type thermometers with a minimum 36-inch stainless steel stem allow measurement of temperatures in the interior of the composting pile. Temperatures should rise to the 130 to 160 degree F range for good composting.

A manure spreader should be available for field spreading finished compost. A conventional beater-type spreader for handling solid manure is also adequate for land applying finished compost.

A logbook is a useful record-keeping tool in a composting operation. Dates and weights of carcasses placed in the composter provide a record of death losses and a basis for improving death loss statistics. Temperature readings, amounts of fresh sawdust inventoried and used and dates when compost is transferred from primary to secondary bins are record-keeping items that can aid in managing the composting operation. Finally, dates and amounts of finished compost removed for land spreading also provide data for future management and planning.

Although composters are simple and relatively easy to operate and manage, certain steps and procedures are necessary to ensure that the process proceeds properly. Table 3 outlines the steps that should provide acceptable finished compost in a swine operation.

Table 3.

Steps in operating and managing a

swine composter

Carcasses placed in warm sawdust begin composting more quickly. This can be accomplished by overfilling sawdust over the previous carcasses. This allows the sawdust to heat up so that the next carcass is then buried in this pre-warmed sawdust. The loader bucket is used to "wallow-out" a cavity in the pre-warmed sawdust and the fresh carcass is placed in this cavity. If finished compost is available, it should be used to cover the carcass to provide additional heat and bacteria to start the composting process. Fresh sawdust should then be used to provide the final cover thickness needed so a new cavity can be provided for the next carcass.

| Fertilizer nutrients, lbs./ton wet basis | |||||

| Dry matter | Total nitrogen | Ammonia nitrogen | P2O5 | K2O | |

| Finished compost | 1,000 | 20 | 4 | 2 | 6 |

| Fresh sawdust | 800 | 1 | 0 | 0.2 | 0.4 |

Certain questions regarding composting frequently arise. Some of these questions and answers are as follows.

![]() If carcasses are properly covered with sawdust (one foot recommended),

odors are sufficiently suppressed or absorbed so that they are not a problem in

most cases. When operated properly, composters do not add to, or increase odor

levels around a production facility. Using too little sawdust is the single

greatest factor in excess odor and associated rodent problems. It is important

to prevent a rodent problem when starting up a composter, because once rodents

learn the composter is a source of carcasses, they can be difficult to stop.

If carcasses are properly covered with sawdust (one foot recommended),

odors are sufficiently suppressed or absorbed so that they are not a problem in

most cases. When operated properly, composters do not add to, or increase odor

levels around a production facility. Using too little sawdust is the single

greatest factor in excess odor and associated rodent problems. It is important

to prevent a rodent problem when starting up a composter, because once rodents

learn the composter is a source of carcasses, they can be difficult to stop.

![]() In general, the warmer the ambient temperature, the better the

composting process works. However, an active compost pile contains considerable

heat which, with the insulating effect of the sawdust, minimizes effects of

ambient temperatures. Interior pile temperatures of 130 to 160 degrees F are

typical in properly operating composters when ambient temperatures are as low as

zero degrees F. Cold or frozen carcasses placed in cold (fresh) sawdust will not

begin composting during cold weather. However, carcasses placed under these

conditions will begin to compost as ambient temperatures warm up in the spring.

In general, the warmer the ambient temperature, the better the

composting process works. However, an active compost pile contains considerable

heat which, with the insulating effect of the sawdust, minimizes effects of

ambient temperatures. Interior pile temperatures of 130 to 160 degrees F are

typical in properly operating composters when ambient temperatures are as low as

zero degrees F. Cold or frozen carcasses placed in cold (fresh) sawdust will not

begin composting during cold weather. However, carcasses placed under these

conditions will begin to compost as ambient temperatures warm up in the spring.

Carcasses placed in an active compost pile during cold weather should begin composting as heat is absorbed from the composting mass. Covering the carcass with warm or hot finished compost from an active secondary bin will further enhance composting fresh carcasses in cold ambient temperatures.

![]() Mature sows and boars (300 to 600 pounds) have been successfully

composted. Longer composting times are required for larger carcasses. However,

six months of active (temperatures 130 degrees F or above) composting time

should be sufficient for most swine carcasses. These carcasses are composted

whole (no cleaving or cutting up of the carcass).

Mature sows and boars (300 to 600 pounds) have been successfully

composted. Longer composting times are required for larger carcasses. However,

six months of active (temperatures 130 degrees F or above) composting time

should be sufficient for most swine carcasses. These carcasses are composted

whole (no cleaving or cutting up of the carcass).

![]() The primary concern of the regulatory agency is to prevent

contamination of ground or surface water. Hence, any contamination problem

arising from a composter (or any other part of the production facility) would

have to be corrected. Contamination potential from composters located and

operated as indicated in this publication is quite low. Under current policy,

Missouri DNR will approve unroofed swine composters if sawdust is used as the

carbon source and the composter is properly managed. Use of other carbon sources

such as straw will likely require a roofed structure to minimize water

absorption and leaching.

The primary concern of the regulatory agency is to prevent

contamination of ground or surface water. Hence, any contamination problem

arising from a composter (or any other part of the production facility) would

have to be corrected. Contamination potential from composters located and

operated as indicated in this publication is quite low. Under current policy,

Missouri DNR will approve unroofed swine composters if sawdust is used as the

carbon source and the composter is properly managed. Use of other carbon sources

such as straw will likely require a roofed structure to minimize water

absorption and leaching.

![]() Properly finished compost should appear as a dark, nearly black

granular material resembling humus or potting soil. It may have a slight musty

odor. Some resistant bones (skull parts, teeth) will be visible, but they should

be soft and easily crumbled by hand.

Properly finished compost should appear as a dark, nearly black

granular material resembling humus or potting soil. It may have a slight musty

odor. Some resistant bones (skull parts, teeth) will be visible, but they should

be soft and easily crumbled by hand.

![]() Temperatures above 140 degrees F normally occur at some time in the

composting pile. This is sufficient to destroy pathogens and prevent fly

incubation. Good coverage of the composting pile with sawdust eliminates the fly

breeding and incubation environment. No disease outbreaks have been associated

with composting to date. Spreading finished compost in fields or pastures helps

assure that disease organisms do not find their way back to the production area.

Temperatures above 140 degrees F normally occur at some time in the

composting pile. This is sufficient to destroy pathogens and prevent fly

incubation. Good coverage of the composting pile with sawdust eliminates the fly

breeding and incubation environment. No disease outbreaks have been associated

with composting to date. Spreading finished compost in fields or pastures helps

assure that disease organisms do not find their way back to the production area.

![]() Any granular organic material with a high carbon content should be a

candidate as an ingredient in composting. Most successful swine composting thus

far has been accomplished using sawdust as the carbon source. More research and

experience is needed to evaluate other carbon sources such as straw, hay, rice

hulls and cornstalks. A long, fibrous material such as straw or cornstalks would

likely work much better for composting if it were ground to reduce the particle

size similar to that of sawdust. This would allow the material to settle around

the carcass and provide the contact needed for good bacterial activity.

Any granular organic material with a high carbon content should be a

candidate as an ingredient in composting. Most successful swine composting thus

far has been accomplished using sawdust as the carbon source. More research and

experience is needed to evaluate other carbon sources such as straw, hay, rice

hulls and cornstalks. A long, fibrous material such as straw or cornstalks would

likely work much better for composting if it were ground to reduce the particle

size similar to that of sawdust. This would allow the material to settle around

the carcass and provide the contact needed for good bacterial activity.

![]() Experience to date indicates that up to 50 percent of the fresh sawdust

requirement may be fulfilled using finished compost. It is unlikely that

long-term viability of the process could be maintained if no fresh sawdust were

used, as the source of carbon would eventually be exhausted. Advantages of

recycling finished compost include: less fresh sawdust required, active bacteria

and heat contained in finished compost and less finished compost to haul for

land spreading.

Experience to date indicates that up to 50 percent of the fresh sawdust

requirement may be fulfilled using finished compost. It is unlikely that

long-term viability of the process could be maintained if no fresh sawdust were

used, as the source of carbon would eventually be exhausted. Advantages of

recycling finished compost include: less fresh sawdust required, active bacteria

and heat contained in finished compost and less finished compost to haul for

land spreading.

![]() Excessive moisture in the composting pile is the most frequent cause of

leaching and failure of carcasses to compost properly. The use of adequate

amounts of dry or nearly dry sawdust is the best way to eliminate excessive

moisture. Any surface water should be diverted around and away from the

composter. If a composting pile becomes too wet, it can usually be recovered by

moving it to another bin, and mixing in additional dry ingredients during the

moving process.

Excessive moisture in the composting pile is the most frequent cause of

leaching and failure of carcasses to compost properly. The use of adequate

amounts of dry or nearly dry sawdust is the best way to eliminate excessive

moisture. Any surface water should be diverted around and away from the

composter. If a composting pile becomes too wet, it can usually be recovered by

moving it to another bin, and mixing in additional dry ingredients during the

moving process.

![]() Finished dead animal compost, which is not recycled in primary bins,

should be spread following agronomic practices used for spreading manure.

Compost should be spread at agronomic rates so that applied nutrients do not

exceed the uptake capabilities of the crop being grown. Conventional

"beater-type" manure spreaders are ideal for handling and spreading compost.

Care should be taken not to spread compost in or near sensitive areas such as

streams, lakes, ponds, sinkholes, public rights-of-way and road ditches.

Finished dead animal compost, which is not recycled in primary bins,

should be spread following agronomic practices used for spreading manure.

Compost should be spread at agronomic rates so that applied nutrients do not

exceed the uptake capabilities of the crop being grown. Conventional

"beater-type" manure spreaders are ideal for handling and spreading compost.

Care should be taken not to spread compost in or near sensitive areas such as

streams, lakes, ponds, sinkholes, public rights-of-way and road ditches.

![]() Moving compost from primary to secondary bins provides mixing, adds

oxygen, and allows the compost to "finish off" with a high degree of breakdown.

The success of the primary/secondary approach has been demonstrated in many

other areas of composting, as well as swine. Some producers have reported

acceptable results with single-step composting, but total composting time may be

longer than that required for primary/secondary composting. Also, bin volume

requirements are not reduced by single-step composting.

Moving compost from primary to secondary bins provides mixing, adds

oxygen, and allows the compost to "finish off" with a high degree of breakdown.

The success of the primary/secondary approach has been demonstrated in many

other areas of composting, as well as swine. Some producers have reported

acceptable results with single-step composting, but total composting time may be

longer than that required for primary/secondary composting. Also, bin volume

requirements are not reduced by single-step composting.

![]() Generally, the dryer the sawdust, the better, since dryer sawdust can

absorb more water. However, producers have reported success when using green

sawdust for some or all of the fresh sawdust requirement. Sawdust containing

excessive moisture may freeze into chunks in the winter, making it difficult to

handle and place around carcasses.

Generally, the dryer the sawdust, the better, since dryer sawdust can

absorb more water. However, producers have reported success when using green

sawdust for some or all of the fresh sawdust requirement. Sawdust containing

excessive moisture may freeze into chunks in the winter, making it difficult to

handle and place around carcasses.

![]() Experience with large swine carcasses (600 to 700 pounds) suggest that

cattle carcasses could be composted in this manner if properly managed. Large

cattle carcasses will be more difficult to handle and properly place in a

composter. Required composting time is proportional to carcass weight, hence

large cattle carcasses may require up to a year of active composting time. Also,

more movement, mixing, and aeration of the composting pile may be necessary. It

is likely that more sawdust per pound of carcass will be required with cattle

carcasses due to the amount required for adequate coverage of the legs and head.

No experience has been gained to date to provide information similar to that in

Table 1 for cattle.

Experience with large swine carcasses (600 to 700 pounds) suggest that

cattle carcasses could be composted in this manner if properly managed. Large

cattle carcasses will be more difficult to handle and properly place in a

composter. Required composting time is proportional to carcass weight, hence

large cattle carcasses may require up to a year of active composting time. Also,

more movement, mixing, and aeration of the composting pile may be necessary. It

is likely that more sawdust per pound of carcass will be required with cattle

carcasses due to the amount required for adequate coverage of the legs and head.

No experience has been gained to date to provide information similar to that in

Table 1 for cattle.

The examples on the following pages, used with the Swine composter worksheet, illustrate a method of sizing a swine composter, and estimating annual sawdust requirements.

Size a composter for a 200-sow, farrow-to-finish operation. Use data in Table 2 to estimate death loss. Estimate annual sawdust requirements. There are 200 mature animals (sows, boars, gilts), 700 nursery pigs, and 1,640 finishing pigs in the operation.

1. Calculate weight of carcasses composted. Use data from actual experience, or use Table 2.

Sow herd

No. of sows x avg. wt. x percent (Table 2) ÷ 100 = lbs. loss/year

_200_ x _375_ lbs. x _7_ percent ÷ 100 = _5,250_ lbs./year

Nursery

No. of pig spaces x avg. wt. x percent (Table 2) ÷ 100 = lbs. loss/year

_700_ x _32_ lbs. x _24_ percent ÷ 100 = _5,376_ lbs./year

Finishing

No. of pig spaces x avg. wt. x percent (Table 2) ÷ 100 = lbs. loss/year

_1,640_ x _150_ lbs. x _11_ percent ÷ 100 = _27,060_ lbs./year

Total = _37,686_ lbs./year

lbs. composted daily = (lbs./year) ÷ 365 = _37,686_ lbs./year ÷ 365 = _103_ lbs./day

2. Calculate primary and secondary bin volume.

lbs. composted daily (Step 1) x 20 = primary bin volume, cu ft

_103_ lbs./day x 20 = _2,060_ cu ft primary bin volume

lbs. composted daily (Step 1) x 20 = secondary bin volume, cu ft

_103_ lbs./day x 20 = _2,060_ cu ft secondary bin volume

3. Calculate bin area (use volumes from Step 2).

bin volume, cu ft ÷ depth (usually 5-6 ft) = bin area, sq ft

_2,060_ cu ft ÷ _6_ ft = _343_ sq ft primary bin

bin volume, cu ft ÷ depth (usually 5-6 ft) = bin area, sq ft

_2,060_ cu ft ÷ _6_ ft =_343_ sq ft secondary bin

4. Calculate number of bins (at least 3 bins required).

primary bin area (Step 3) ÷ (100 - 200 sq ft/bin) = No. of bins

_343_ sq ft ÷ _110_ sq ft/bin = _3.1_ primary bins

secondary bin area (Step 3) ÷ (100 - 200 sq ft/bin) = No. of bins

_343_ sq ft ÷ _110_ sq ft/bin = _3.1_ secondary bins

5. Calculate bin dimensions.

bin depth = composting depth (usually 5-6 ft) = _6_ ft depth

bin width = loader bucket width + 2 ft or wider = _10_ ft width

bin length = bin area (Step 3) ÷ bin width = _110_ sq ft ÷ _10_ ft = _11_ ft length

6. Calculate annual sawdust requirements.

lbs. composted/year (Step 1) x 0.0037 = cu yd sawdust/year

_37,686_ lbs./year x 0.0037 = _139_ cu yd sawdust/year

Size a composter for a 2,400-sow farrowing operation. Death loss data for the operation is as follows:

Four 375 lb. sows/week

200 lb. small pigs and afterbirth per day

Calculate annual and daily carcass weight and enter directly in Step 1 of the worksheet.

375 lb. sow x 4 sows/week x 52 weeks/year = 78,000 lbs./year

200 lb. pigs and afterbirth/day x 365 days/year = 73,000 lbs./year

Total = 151,000 lbs./year = 414 lbs./day

1. Calculate weight of carcasses composted. Use data from actual experience, or use Table 2.

Sow herd

No. of sows x avg. wt. x percent (Table 2) ÷ 100 = lbs. loss/year

___ x ___ lbs. x ___ percent ÷ 100 = ___ lbs./year

Nursery

No. of pig spaces x avg. wt. x percent (Table 2) ÷ 100 = lbs. loss/year

___ x ___ lbs. x ___ percent ÷ 100 = ___ lbs./year

Finishing

No. of pig spaces x avg. wt. x percent (Table 2) ÷ 100 = lbs. loss/year

___ x ___ lbs. x ___ percent ÷ 100 = ___ lbs./year

Total = _151,000_ lbs./year

lbs. composted daily = (lbs./year) ÷ 365 = _151,000_ lbs./year ÷ 365 = _414_ lbs./day

2. Calculate primary and secondary bin volume.

lbs. composted daily (Step 1) x 20 = primary bin volume, cu ft

_414_ lbs./day x 20 = _8,280_ cu ft primary bin volume

lbs. composted daily (Step 1) x 20 = secondary bin volume, cu ft

_414_ lbs./day x 20 = _8,280_ cu ft secondary bin volume

3. Calculate bin area (use volumes from Step 2).

bin volume, cu ft ÷ depth (usually 5-6 ft) = bin area, sq ft

_8,280_ cu ft ÷ _6_ ft = _1,380_ sq ft primary bin

bin volume, cu ft ÷ depth (usually 5-6 ft) = bin area, sq ft

_8,280_ cu ft ÷ _6_ ft = _1,380_ sq ft secondary bin

4. Calculate number of bins (at least 3 bins required).

primary bin area (Step 3) ÷ (100 - 200 sq ft/bin) = No. of bins

_1,380_ sq ft ÷ _170_ sq ft/bin = _8.1_ primary bins

secondary bin area (Step 3) ÷ (100 - 200 sq ft/bin) = No. of bins

_1,380_ sq ft ÷ _170_ sq ft/bin = _8.1_ secondary bins

5. Calculate bin dimensions.

bin depth = composting depth (usually 5-6 ft) = _6_ ft depth

bin width = loader bucket width + 2 ft or wider = _12_ ft width

bin length = bin area (Step 3) ÷ bin width = _170_ sq ft ÷ _12_ ft = _14_ ft length

6. Calculate annual sawdust requirements.

lbs. composted/year (Step 1) x 0.0037 = cu yd sawdust/year

_151,110_ lbs./year x 0.0037 = _559_ cu yd sawdust/year

Size a composter for an off-site nursery with a capacity of 8,400 pigs. Average weight in the nursery is 27 pounds. Use data in Table 2 to estimate death loss.

1. Calculate weight of carcasses composted. Use data from actual experience, or use Table 2.

Sow herd

No. of sows x avg. wt. x percent (Table 2) ÷ 100 = lbs. loss/year

___ x ___ lbs. x ___ percent ÷ 100 = ___ lbs./year

Nursery

No. of pig spaces x avg. wt. x percent (Table 2) ÷ 100 = lbs. loss/year

_8,400_ x _27_ lbs. x _24_ percent ÷ 100 = _54,432_ lbs./year

Finishing

No. of pig spaces x avg. wt. x percent (Table 2) ÷ 100 = lbs. loss/year

___ x ___ lbs. x ___ percent ÷ 100 = ___ lbs./year

Total = _54,432_ lbs./year

lbs. composted daily = (lbs./year) ÷ 365 =_54,432_ lbs./year ÷ 365 = _149_ lbs./day

2. Calculate primary and secondary bin volume.

lbs. composted daily (Step 1) x 20 = primary bin volume, cu ft

_149_ lbs./day x 20 = _2,980_ cu ft primary bin volume

lbs. composted daily (Step 1) x 20 = secondary bin volume, cu ft

_149_ lbs./day x 20 = _2,980_ cu ft secondary bin volume

3. Calculate bin area (use volumes from Step 2).

bin volume, cu ft ÷ depth (usually 5-6 ft) = bin area, sq ft

_2,980_ cu ft ÷ _6_ ft = _497_ sq ft primary bin

bin volume, cu ft ÷ depth (usually 5-6 ft) = bin area, sq ft

_2,980_ cu ft ÷ _6_ ft = _497_ sq ft secondary bin

4. Calculate number of bins (at least 3 bins required).

primary bin area (Step 3) ÷ (100 - 200 sq ft/bin) = No. of bins

_497_ sq ft ÷ _160_ sq ft/bin = _3.1_ primary bins

secondary bin area (Step 3) ÷ (100 - 200 sq ft/bin) = No. of bins

_497_ sq ft ÷ _160_ sq ft/bin = _3.1_ secondary bins

5. Calculate bin dimensions.

bin depth = composting depth (usually 5-6 ft) = _16_ ft depth

bin width = loader bucket width + 2 ft or wider = _10_ ft width

bin length = bin area (Step 3) ÷ bin width = _160_ sq ft ÷ _10_ ft = _16_ ft length

6. Calculate annual sawdust requirements.

lbs. composted/year (Step 1) x 0.0037 = cu yd sawdust/year

_54,432_ lbs./year x 0.0037 = _201_ cu yd sawdust/year

1. Calculate weight of carcasses composted. Use data from actual experience, or use Table 2.

Sow herd

No. of sows x avg. wt. x percent (Table 2) ÷ 100 = lbs. loss/year

___ x ___ lbs. x ___ percent ÷ 100 = ___ lbs./year

Nursery

No. of pig spaces x avg. wt. x percent (Table 2) ÷ 100 = lbs. loss/year

___ x ___ lbs. x ___ percent ÷ 100 = ___ lbs./year

Finishing

No. of pig spaces x avg. wt. x percent (Table 2) ÷ 100 = lbs. loss/year

___ x ___ lbs. x ___ percent ÷ 100 = ___ lbs./year

Total = ___ lbs./year

lbs. composted daily = (lbs./year) ÷ 365 = ___ lbs./year ÷ 365 = ___ lbs./day

2. Calculate primary and secondary bin volume.

lbs. composted daily (Step 1) x 20 = primary bin volume, cu ft

___ lbs./day x 20 = ___ cu ft primary bin volume

lbs. composted daily (Step 1) x 20 = secondary bin volume, cu ft

___ lbs./day x 20 = ___ cu ft secondary bin volume

3. Calculate bin area (use volumes from Step 2).

bin volume, cu ft ÷ depth (usually 5-6 ft) = bin area, sq ft

___ cu ft ÷ ___ ft = ___ sq ft primary bin

bin volume, cu ft ÷ depth (usually 5-6 ft) = bin area, sq ft

___ cu ft ÷ ___ ft = ___ sq ft secondary bin

4. Calculate number of bins (at least 3 bins required).

primary bin area (Step 3) ÷ (100 - 200 sq ft/bin) = No. of bins

___ sq ft ÷ ___ sq ft/bin = ___ primary bins

secondary bin area (Step 3) ÷ (100 - 200 sq ft/bin) = No. of bins

___ sq ft ÷ ___ sq ft/bin = ___ secondary bins

5. Calculate bin dimensions.

bin depth = composting depth (usually 5-6 ft) = ___ ft depth

bin width = loader bucket width + 2 ft or wider = ___ ft width

bin length = bin area (Step 3) ÷ bin width = ___ sq ft ÷ ___ ft = ___ ft length

6. Calculate annual sawdust requirements.

lbs. composted/year (Step 1) x 0.0037 = cu yd sawdust/year

___ lbs./year x 0.0037 = ___ cu yd sawdust/yearRynk, Robert, et. al. 1992, NRAES-54

U.S. Department of Agriculture, Wood Handbook. Handbook No. 72, U.S. Department of Agriculture, Forest Products Laboratory.

Starbuck, Chris, et. al. 1994. Developing Procedures for Utilizing Missouri Sawdust in Combination with other Organic Byproducts for Large Scale Horticultural Uses. Unpublished report, Department of Horticulture, University of Missouri, Columbia, Mo.

The author expresses his deep appreciation to Mel Gerber, Versailles, Mo. for his initiative and extensive cooperation and efforts in applied field research on swine composting. Many of the design and management recommendations for composting are derived from Mel's early experiences and his desire to share those experiences for the benefit of the swine industry.

This publication was formerly printed as WQ0225.

Web maintenance 8/30/05

Reviewed August 1996