RE-Cycle: a profitable swine

production system with zero waste

Presented previously at the 2003 Banff Pork Seminar,

Advances in Pork Production, Vol. 14, pp. 195-206

North Carolina State University, Department of Animal Science

Technology Partners

Belt design: Preston Burnette, Brett Kaspers, and Jeanne Koger, NCSU

Economic evaluation: Tullaya Boonsaeng and Ada Wossink, NCSU

Gasification/liquefaction: Deola Ali, Preston Burnette, Jeanne Koger, and Jerry Spivey, NCSU

Ammonia recovery process: Paul Loeffler, Sam Houston State University, and Alex Fassbender, ThermoEnergy, Inc. (http://www.thermoenergy.com/)

Introduction

Traditionally, swine production and crop production were tightly integrated. Swine were raised on crop residues, and their manure was a valuable fertilizer. Over the past 40 years, however, both crop producers and swine producers have moved away from this integration in an effort to reduce production costs. Crop producers prefer ‘pure’ fertilizers that are easy and accurate to spread, while swine producers prefer to hold animals in large groups in close proximity to feed mills and slaughter plants. Feed ingredients are often imported from distant regions making it financially prohibitive to return the highly dilute manure to the crop-growing areas. Thus, manure ends up being used locally, sometimes at application rates that exceed crop requirements.

This type of swine production has raised environmental concerns and some environmentalists push for a reintegration of crop and swine production through a return to much smaller, diversified family farms. Although components of the RE-Cycle system can facilitate such a movement, the RE-Cycle system is really meant as a solution for the environmental concerns of very large, integrated swine facilities.

The RE-Cycle system is designed to convert waste into value added products (Figure 1). Fecal material is converted into energy and ash. The energy can be captured in the form of electricity or a liquid fuel such as diesel or ethanol. The sterile ash has been successfully used as a mineral supplement in swine feed, eliminating phosphorus as an environmental concern. Nitrogen is recovered and processed into commercial grade nitrogen fertilizer, eliminating nitrogen as an environmental concern.

Figure 1. Faith of nutrients in the RE-Cycle System.

The components that make up the RE-Cycle system are all based on existing technology and can be used independently of each other. Central to the system is a modified swine housing system in which a conveyer belt is used for separating urine and feces in the house itself, substantially reducing ammonia and odor emission. Urine is processed on the farm through a reversible chemisorption system for extraction of ammonia. The extracted ammonia is processed centrally into commercial-grade fertilizer. Partially dried feces are also shipped to this central processing facility for energy recovery.

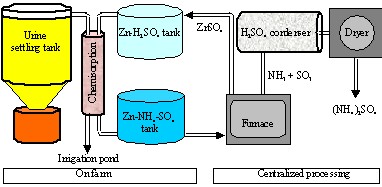

A schematic overview of the RE-Cycle system is shown in Figure 2, and a more detailed description of each of the steps in the system is provided below.

Figure 2. Overview of the RE-Cycle System. Top: Swine feces are collected on a belt system placed in the barn, and are harvested in a dry state. These feces are transported to a centralized steam reforming gasification/liquefaction plant where they are recombined to form a liquid fuel or used for electricity production. Bottom: Urine is continuously removed from the building using gravity. Ammonia is then extracted using an ion-exchange process yielding zinc-ammonium-sulfate which is transported to a centralized processing plant and turned into ammonium-sulfate, which is sold as fertilizer. Remaining water is used for irrigation.

Conveyor-belt based swine housing.

Conveyor belts have been used in the laying hen industry for approximately 30 years with good success. They require minimal intervention, last 8 to 10 years, and allow for the poultry waste to be collected in a dry form with minimal ammonia and odor emission. The major challenge with pigs is that pigs produce a large volume of urine, which has to be separated from the feces. To achieve this, the belt should be placed at an angle such that the urine runs away from the feces.

Typical behavior of pigs is to defecate against back walls of pens or against open partitions between pens, and this behavior can be utilized in constructing a belt-based housing system. Using a partially-slatted housing system as a starting point, belts with a width of approximately 2m are placed in the existing flush-gutter such that the highest end of the belt is against the back wall, sloping inward at approximately 4° (Figure 3). At the low end of the belt, a gutter is installed below the belt or the belt is bent back upwards to generate a urine gutter. The advantage of a separate gutter is that ammonia emission can be maximally reduced, but the disadvantage is that solids (especially spilled feed) can settle in the gutter leading to clogs and odor. The advantage of the gutter integrated in the belt is that the gutter is cleaned whenever the belt operates. However, the gutter residue can lower the dry matter content of the feces collected.

For an optimal climate in the swine barn, it is paramount that the urine be removed from the barn as soon as possible. This is because fecal contamination of urine results in the breakdown of urea to form ammonia, which can be volatilized. Ammonia has a negative effect on animal and worker health and well-being and has been implicated in eutrophication. In buildings that are placed on a slope and that use the above belt design, the urine continuously flows out of the building. Research has shown reductions in ammonia of 65 to 80% depending on the extent of pen fouling. Actual ammonia concentrations measured in a facility with a ventilation rate of approximately 50 m3/h/pig place were 2-3 ppm. A benefit of removing urine from the building is a marked reduction in odor as odor is linked to aging urine. In experiments with the belt, this has resulted in a 5% improvement in feed efficiency compared to animals in conventional facilities.

Figure 3. Belt setup in a conventional, partially slatted, swine house. A polypropylene belt is placed at a 4° angle in the pit such that urine runs off into a collection pipe, while feces stay on the belt and dry passively. Feces are collected daily at 6 am at a dry matter content of approximately 53%. Benefits of separating urine and feces are a dry fecal waste stream and substantially reduced ammonia and odor emission.

To harvest the feces with the highest dry matter content possible, it was originally believed that the residence time on the belt was of importance. The longer the feces sat on the belt, the more time it had to dry. This assumption turned out to be false. After a day, feces accumulate on the belt to a point that urine does not run through it freely, trapping the urine and creating puddles. What was observed, however, was that the time of collection was of major importance. Feces collected late in the afternoon were the wettest; those collected early in the morning, the driest. The reason for this is simple. Pigs are asleep most of the night and thus do not urinate. During this time the feces dry. During the day, the pigs urinate decreasing the dry matter content of the feces. Harvesting feces at 6 am has proven very effective, with dry matters averaging 53%. At this point the feces are dry to the touch, don’t clump, and are stable when stored. In a commercial setting, these feces can be conveyed to a truck bed for collection or to a composting shed.

In

summary:

Steam reforming gasification

is a form of thermal decomposition in an environment with limited or no

oxygen. The concept is that material is indirectly heated to very high

temperatures, for example, 800°C, at which point organic material

decomposes into gases such as H2, CO, CO2, and

CH4, and ash containing minerals. A benefit of this process is

that any bio-active compound, such as antibiotics, prions, or viruses,

should be destroyed. The steam reforming gasifier

used for research at NCSU uses an entrained flow principle. The swine

feces are injected into a spiral tube while suspended by superheated steam

and some recycled product gas (Figure 4). This tube surrounds an intense

flame, and while traveling up this tube the material is heated to 800°C

and decomposes. The reason for co-injecting product gas is to propel the

material through the tube. Steam is injected so it can react with fecal

material resulting in H2 production. In principle, the reaction

occurring is as described below. In practicality, other product gases such

as CO2, CH4, H2S, and NH3 are

formed as well. C2H4O +

H2O → 2CO + 3H2 At the exit of the decomposition tube, the product

gas is separated from the mineral ash using cyclones and gas cleaners. The

product gas has a combustion value similar to low grade natural gas and

can be used to fuel a generator or micro-turbine for the production of

electricity. This is only a viable option if a market is available for

electricity.

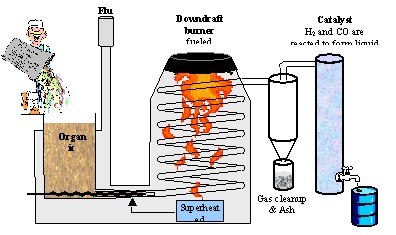

Figure 4. Schematic diagram of gasification and

liquefaction plant. Organic waste such as swine feces are introduced into

a coil that is heated using a downdraft burner. This causes the material

to decompose into hydrogen and carbon monoxide, which, after cleanup, is

catalytically combined into a liquid fuel such as ethanol or diesel.

Residual heat from the downdraft burner is first used to generated

superheated steam, which is injected with the organic material. Remaining

heat is used to pre-dry the organic waste. Ash remaining after

gasification is collected using a cyclone.

Another possibility is to catalytically recombine

these gases to produce products such as ethanol or diesel. This is

typically achieved by compressing the gases and injecting them at a high

temperature into a matrix of, for example, molybdenum sulfide for the

production of ethanol or iron silicon dioxide for the production of

diesel. This option is technically and financially (higher investment)

more challenging but as fuels are produced that can be stored and

transported, it may be the preferred option in situations where there is

no market for electricity. The steam reforming gasifier

does not require external energy for its operation. Instead, a portion of

the product gas or, in the case of catalytic conversion of product gas to

liquid fuels, unreacted product gas, is used to fuel the burner that

generates the heat to sustain the process. Thus, the entire process is

self-sustaining and equally important, the process does not produce any

air emission of noxious compounds such as dioxins. In summary:

Using grower feed as a starting point, approximately

15% of the feed mass is converted to dry swine feces. Upon steam reforming

gasification, approximately 13% of the fecal mass is converted to ash.

Thus, per kg of grower feed 20 grams of ash are produced, or 2%. This ash

contains most of the minerals that were in the swine feces in either oxide

or carbonate form. Exceptions are sulfur, chloride, and nitrogen, which

are trapped in the wash liquid of the product gas. The ash (composition in

parenthesis) is rich in elements such as Ca (11.5%), P (13.3%), and Mg

(5.8%) as these minerals are predominantly excreted in the feces. Sodium

(2.8%) and potassium (12.2%) are mainly excreted in the urine and they are

not the predominant minerals in feces. The ash recovered from the

gasifier has been exposed to temperatures of 800°C and is thus sterile.

Therefore, from a disease perspective it is perfectly safe to feed this

ash back to pigs. The mineral digestibility of

the ash has been evaluated both in pigs and under lab conditions. Results

of both assays were in agreement and showed that the digestibility of

minerals in ash was practically equivalent to the mineral digestibility in

commercial sources of these minerals (for example, limestone and dicalcium

phosphate). This means that the ash becomes a value-added product in the

RE-Cycle system. Formulating a diet based on

this ash composition showed that, for grower pigs, the inclusion in the

diet of 2% ash (treated with hydrochloric acid to reduce the pH and

provide chloride), 0.15% salt, and 0.6% limestone provided all the macro

and micro minerals needed by the pig. At this inclusion rate, a nearly

perfect balance exists between ash production and ash utilization.

Thus, the RE-Cycle system is expected to not have a significant net

surplus or deficiency of phosphorus. In

summary: Pigs excrete approximately 70%

of waste nitrogen in urine, mainly in the form of urea. It is this urea

that is broken down quickly to result in ammonia emission in conventional

swine housing systems. By minimizing contact between the urine and the

feces and by removing the urine from the house as soon as possible,

ammonia emission can be prevented. This urine is a good source of

nitrogen fertilizer, but as collected it is rather dilute, unstable, and

smelly (after short-term storage), making land application not an ideal

solution except when using an injection system under dry weather

conditions. An alternative method for managing the nitrogen is to

nitrify/denitrify it, as is done in many municipal waste-treatment plants.

In such a system bacteria first oxidize the ammonia to form nitrates, and

then, in a second step, reduce the nitrate to N2 gas. Nitrogen

gas makes up 80% of the atmosphere and can be safely released into the

atmosphere. Although technically a good option, this process does not

produce any value-added products and results in the loss of a valuable

resource, fertilizer N.

An alternative solution is to

trap the ammonia from urine using, for example, a reversible chemisorption

system such as the Ammonia Recovery Process or ARP (Figure 5). This ARP

consists of a column containing a zinc-based resin that reversibly binds

ammonia. When urine passes through this column, nearly all of the ammonia

(up to 99.7%) binds to the column, and the remaining ‘urine’ can be used

as irrigation water since it is virtually free of nitrogen and phosphorus.

Ammonia that is bound to the column is periodically removed by flushing

the column with a strong acid solution. The resulting solution of

zinc-ammonium-sulfate is transported to a centralized processing facility.

Figure 5. Schematic diagram of the Ammonia Recovery

System. On-farm ammonia is removed from urine using an ion-exchange

column. The collected ammonia is removed from this column uning

concentrated zinc sulfuric acid resulting in a zinc-ammonium-sulfate

solution. This solution is processed centrally using a furnace, resulting

in ammonia and zinc sulfate. The zinc sulfate is used to regenerate the

ion-exchange column. Ammonia is reacted with sulfuric acid to form

ammonium sulfate, a commercial-grade fertilizer.

The remaining 30% of the nitrogen excreted by the

pigs ends up in the steam-reforming gasifier. There it is also converted

to ammonia gas, which is trapped in the gas cleanup. Both the

zinc-ammonium sulfate solution and the ammonia from the gasifier are

introduced into a furnace (using residual heat from the steam-reforming

gasifier), resulting in the production of ammonia gas and zinc sulfate.

The zinc sulfate is returned to the farm for regeneration of the

ion-exchange column. Ammonia is trapped in a scrubber column loaded with

sulfuric acid, and the resulting solution of ammonium sulfate is dried to

form fertilizer-grade ammonium sulfate. In

summary: The Combined

System The system in its entirety is

designed for an area with a high concentration of pigs. Ideally, at least

500,000 grow-finish pigs are within a 15 to 20 km radius from the

centralized processing plant to minimize transport costs. Other biomass

sources such as poultry litter, wood, or municipal waste, can be used to

provide additional fuel. From an energy perspective,

the outlined system would process approximately 250 tons of dry fecal

material per day, equivalent to an energy input of 58 MW. Presuming an

efficiency of 40%, electricity output is 23 MW and based on 8000 h of

operation, 186 GWh per year. This is roughly equivalent to the electricity

requirement of 20,000 households. If the end product is a liquid fuel such

as ethanol, total production is estimated at 23 million liters per year.

The economics of the RE-Cycle system are still under

investigation. For the preceding scenario of 500,000 pigs in a radius of

15 to 20 km, the preliminary cost, on a yearly basis, is as follows. The

costs of retrofitting existing barns with a belt are estimated at US $7 to

8 per pig place. This is based on individual farms with 4 barns each

holding 1200 pigs and includes the costs of urine processing and feces

storage. Transport cost for the feces and zinc-ammonium sulfate are

estimated at $1.50 to $3.00 per pig place per year. The cost of centrally

processing the feces and zinc ammonium sulfate is estimated at $11 to 12

per pig place. Revenues from fuel, ash, and fertilizer are estimated at

$23 to 28 per pig place. Thus, in the worst-case scenario, the RE-Cycle

system will break even, while in the best-case scenario, the net profit

will be $8.50 per pig place per year. This cost picture does not take into

consideration any improvement in animal health and performance that may

occur, and it does not take into consideration that waste disposal, under

current conditions, has a cost associated with it that can be avoided.

Presuming that per pig place $3 in waste disposal costs can be avoided

with the RE-Cycle system, the revenue from the RE-Cycle system ranges from

$3 to 11.50 per pig place per year. Please note that, since the RE-Cycle

system is not currently operational as a system, these costs and revenues

are estimates. In regions where the density of pigs is insufficient

for the RE-Cycle system, land application of manure is typically a viable

option. To facilitate this land application and to reduce air emissions,

the belt housing system provides several benefits: lower ammonia and odor

emissions, and a dry, storable fecal waste stream. The latter is high in

phosphorus while urine is high in nitrogen, and thus the belt housing

system allows for precision application of nitrogen and phosphorus.

Steam Reforming Gasification and Liquefaction

Recycling of Ash

Recycling of Nitrogen

Back

Page Back

Page

|