|

Capitalize on Carbon's Capabilities

By Dr.Mick Greenbank and Steve Spotts

It can improve water's taste, remove odors

and reduce toxins.

Summary: Activated carbon products

comprise 13 percent of the $ 1.4 billion domestic water treatment market,

analysts say. Point-of-use products use various forms of the material, but

all share an affinity for contaminants including trihalomethanes and

organochlorides. The medium, however, isn't a panacea.

Over the past three decades, homeowners

hoping to improve their drinking water have turned to point-of-entry (POE)

and point-of-use (POU) water treatment systems. Often the products they use

contain activated carbon, a medium that can improve water's taste and odor

while reducing levels of health-threatening substances.

Quenching U.S. homeowners' thirst for water

treatment is a $1.4 billion industry that grew more than five percent each

of the last three years, according to Baytel Associates, a water treatment

industry market research firm. That trend is expected to continue, with

activated carbon system sales comprising approximately 13 percent of the

overall market, the company says.

Activated carbon is similar to crude

graphite, the material used in pencils. Activated carbon, diamonds and

graphite are the few pure forms of carbon and contain almost no nitrogen,

hydrogen, halogens, sulfur or oxygen.

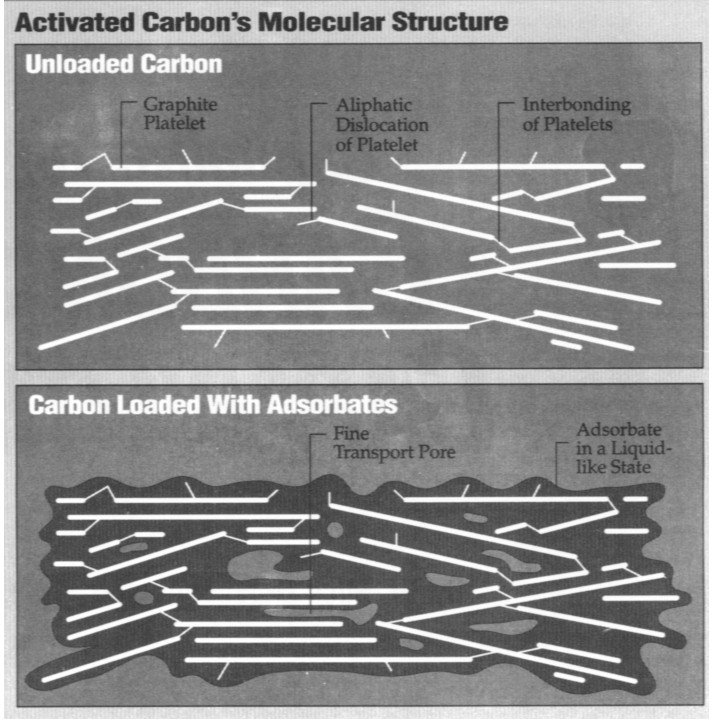

From a chemist's perspective, activated

carbon is an imperfect form of graphite. This imperfect structure results in

a high degree of porosity and more than a million-fold range of pore sizes,

from visible cracks and crevices to gaps and voids of molecular dimensions.

Porosity is what distinguishes activated carbon from graphite or diamonds

and makes it "activated."

Intermolecular attractions in the smallest

pores result in adsorption forces. Carbon adsorption forces are analogous to

gravity, but operate on a molecular, not astronomical, scale. They cause a

reaction similar to precipitation, where adsorbates are removed from

solution.

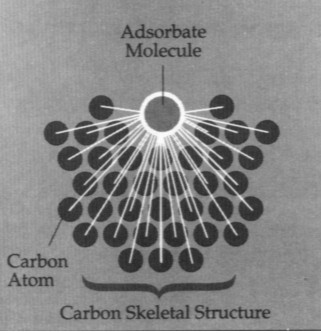

To develop a strong adsorption force, the

distance between the carbon and adsorbate must be decreased by decreasing

its pore size, or the number of carbon atoms in the structure must be

increased by increasing the density of the carbon.

Chemical reactions and chemical bonding can

also occur between the adsorbing molecules and the carbon surface or its

inorganic ash impurities. This is referred to as chemical adsorption or

chemisorption.

Three Carbon Types

Activated carbon comes in three basic forms:

powder, granular and bonded blocks.

- Powdered carbon is used in batches

by municipalities to treat potable water. It's less expensive but

labor-intensive and sometimes troublesome to use, in part because it

must be physically separated from water.

- Granular carbon is simpler to

handle. In most situations, the carbon granules are packed into a vessel

called an "adsorber column" or carbon column. Dimensions and

shapes of carbon columns vary, but their width is generally less than

their length.

The water to be treated flows between the

granules, and adsorption occurs as contaminants diffuse from outside the

particle to the adsorbing pore structures distributed within it. The

contaminant must be in solution to diffuse, then enter the pore structure

and adsorb.

Flow through the carbon column can be up,

down or annular. In all cases, the granules should be immersed in water

for best results.

- Carbon blocks are also used for

water treatment. Using molds, carbon is either extruded or bonded to

form shapes. These shapes are generally placed in some type of filter

housing to direct water flow.

Bonded blocks enable manufacturers to

assemble carbon filters easily. They provide a simple way to handle dusty,

small-mesh granular carbons. They can also physically filter water to

lower particulate levels. Because bonded blocks typically are composed of

fine mesh carbon, adsorption is usually faster than with granular units.

What It Can Do

Physical adsorption is what activated carbon

does best. In POU and POE applications, physical adsorption removes taste

and odor, volatile organic compounds (VOCs), tri-halomethanes (THMs) and

other halocarbons from drinking water.

The physical adsorption process takes time,

however, because adsorbates must move from the particle's exterior to the

adsorption sites within it. Required contact time depends on the amount of

carbon used and flow rated through it. Typical POU devices provide 20 to 40

seconds of contact time.

- Taste and odor removal is an

important ability of activated carbon. Molecules with carbon-sulfur

bonds often smell and taste bad, but these are often preferentially

adsorbed on carbon. The same is true of molecules with aromatic rings.

Carbon treatment helps very little,

however, in cases where tastes and odor arise from small, highly-soluble

molecules like ammonia or methanol.

Adsorption Force

Each carbon molecule attracts adsorbates

into adsorption sites

- VOC removal is another of carbon's

abilities. Chemical analyses show that as many as 1000 compounds can be

present in water, but because adsorption is non-specific, all organic

compounds adsorb on carbon.

Activated carbon, however, differentiates

among these contaminants. The most strongly adsorbed materials have the

highest capacity on the carbon and are efficiently removed.

Weakly-adsorbed components have lower carbon capacities and are the first

to exhaust the carbon column.

THMs and halocarbons are among a special

group of VOCs that are favorably adsorbed. The more chlorine substituted

on a molecule, the more strongly it is adsorbed on carbon, so

carbon-chlorine or carbon-bromine compounds are better adsorbed than

carbon-hydrogen compounds.

THMs and halocarbon vary from weakly- to

strongly-adsorbing. Carbon requirements can therefore vary according to the

concentration of common THM and halocarbon contaminants.

While these carbon requirements relate to

removal of a single component, they show the relative adsorbability of the

different species. For multiple components, carbon requirements can be

approximated by adding the carbon requirement for each individual component.

Activated carbon is also used for more than

physical adsorption. Like graphite, carbon is a reducing agent that reacts

with strong oxidizing agents such as chlorine dioxide, hypochlorous acid and

ozone. It removes free chlorine from potable water using the following

chemical reaction:

HOCl = C (skeleton) fl CO* + HCl

The CO* represents oxidation of the carbon

skeleton by the formation of a carbon-oxygen bond. It may or may not result

in the formation of free carbon monoxide (CO) or carbon dioxide (CO2).

Chlorine removal is slow when HOCl is in the

part per million (ppm) concentration range, so the carbon pore structure

must physically adsorb free chlorine to increase its concentration to the

point where the reaction is accelerated. That's why spent carbon with

physically-adsorbed organics won't concentrate HOCl or induce the rapid

reaction rates required.

Carbon's de-chlorination capacity is

generally determined by its capacity for high molecular weight organics.

Small granules adsorb and react faster than large granules, so some

differences in de-chlorination performance are primarily due to the mesh

size of the particles.

Granular carbon adsorbers can also remove

contaminants through physical filtration. Since physical filtering doesn't

involve adsorption, carbon spent with organics will continue to be an

effective physical filter. A 12x40 mesh carbon column will remove most

suspended solids greater than 10 microns in diameter. The smaller the carbon

mesh size, the more efficient its physical filtration.

Physical filtration is sensitive to the

packing of the carbon granules in the column. The denser the packing, the

more effective it is. Filtered solids may be removed by backwashing the

carbon bed at high flows.

Because bonded blocks of carbon are generally

composed of densely-packed fine particles, it's possible to extend their

physical filtering limits to less than one micron. This can be important for

cyst removal.

What It Can't do

Activated carbon may be the ultimate physical

adsorbent, but it has limitations in POU and POE applications. Carbon

adsorption isn't the technology of choice for:

Water Softening. Activated

carbon has less than one-tenth the ion exchange capacity of good commercial

resins. Activated carbon is ineffective at softening water or removing high

levels of iron.

Desalinating. Everything

adsorbs on carbon to some extent, but highly water-soluble inorganic salts

aren't effectively adsorbed. Cations like potassium, sodium, calcium and

magnesium are seldom adsorbable because of their high solubility in water.

Anions like nitrate, fluoride, sulfate and chloride are also seldom

adsorbable because their salts are highly soluble.

Bactericidal treatment.

Bacteria and algae are much too large to enter the pore structure of

activated carbon. The only means of removing bacteria, algae, or viruses

with activated carbon is by physical filtration. Through some carbon blocks

can be used for physical filtration of larger cysts in water, no carbon can

be used reliably to achieve desinfection.

Heavy metals removal. Carbon's

ability to remove heavy metals like lead, arsenic and mercury depends on

their form. In some cases carbon's physical adsorption properties make it

the best choice for removing heavy metals in the part per billion (ppb)

concentration range, but no recommendation can be made for activated carbon

without a thorough understanding of the forms of heavy metals present.

Activated carbon shouldn't be used for

nitrate and fluoride removal. While it also can't soften or disinfect water,

it enhances water's aestetics through dechlorination and mechanical

filtration. It also enhances health protection by adsorbing synthetic and

natural organic contaminants.

Dr.Mick Greenbank is a senior technical

consultant for Calgon Carbon Corp., Pittsburgh, PA. Steven Spotts is

marketing manager for the company's industrial process group.

Reprinted with permission from WATER

TECHNOLOGY, April 1993. Copyright 1993 by National Trade Publications, Inc.

All Rights Reserved. For reorders - call 612-633-0578

|