|

CARBON CLEAN

A new version of activated carbon controls odors

Gary Van Stone, Daniel Brooks

Controlling odorous emissions has always been

difficult for sewage treatment facilities, particularly for those near

residential areas. But as nearby populations increase and pump stations

transfer more wastewater solids to the plants, odor control is becoming a

bigger challenge. Treatment facilities traditionally have used activated

carbon adsorbers to clean the air. Now, a new type of activated carbon,

catalytic/adsorptive carbon, controls odors better and costs less.

The principal sources of odor in wastewater

operations are septic wastewater containing hydrogen sulfide (H2S)

and other odorous compounds in the plant's pipelines; industrial wastes

discharged to the sewage collection system; unwashed grit; scum on primary

settling tanks; organically overloaded biological treatment processes;

solids thickening tanks; waste-gas burning operations in which lower than

optimum temperatures are used; chemical mixing operations; solids

incinerators; and digested solids in drying beds or solids holding basins.

Odors from these sources vary in degree and

intensity depending on the amount of anaerobic decomposition present.

Hydrogen sulfide, the most prevalent source of all odors, often is

accompanied by mercaptans, indole, skatole, amines, fatty acids and other

volatile organic compounds (VOCs). Odor-control systems typically focus on H2S

because of its low odor threshold (0.47 ppb), predominance as an odorous

agent, and ease of analytical detection.

Activated Carbons

Wastewater treatment facilities use activated

carbon for odor control because of its capacity for adsorbing H2S

and organics (odorous and volatile compounds), and its ease of regeneration

or reactivation. Many facilities effectively control odors by directing air

through a granular, activated carbon adsorber system. Activated carbons

based on bituminous coal, coconut, impregnated bituminous coal and coconut

products typically are used for this application, although each has inherent

strengths and weaknesses.

At 10,000X - magnification,

this image shows the surface characteristics of granular activated carbon.

The performance of coal- and coconut-based

activated carbon is dictated by the classic adsorption theory, which states

that all activated carbon structures are composed of randomly organized

graphitic plates. It is the graphitic plates that produce the energy to

adsorb volatile and odorous organic compounds and H2S. The area

between the graphitic plates, called the activated carbon pore, is where

adsorption occurs. Activated carbons with more graphitic plates usually have

stronger adsorption energy and are better for adsorbing trace volatile and

odorous organic compounds and H2S.

Bituminous- and coconut-activated carbons

readily adsorb volatile and odorous organic compounds, although their

precise adsorption capacity depends on what compounds are present. The

adsorption capacity for inorganic H2S, however, is relatively low

- typically in the range of 0.01-0.02 gm H2S/cc carbon - and

depends on physical adsorption capacity, although chemisorption and

catalytic effects may influence total capacity. Bituminous- and

coconut-activated carbons are not suited for applications in which H2S

is the predominant odorous compound or is present in high concentrations.

After exhausting the adsorption capacity of

bituminous- or coconut-activated carbon, treatment facilities can reactivate

it thermally, restoring it to near its original adsorption capacity. To do

this, the plants remove the carbon from the system; ship it to a

reactivation site; thermally reactivate it and return it to the system for

reuse. Most facilities keep their systems on-line by "swapping

out" exhausted carbon with a spare quantity stored onsite. Once a

facility reactivates the original carbon, the material becomes the spare

quantity so that fresh carbon is always available.

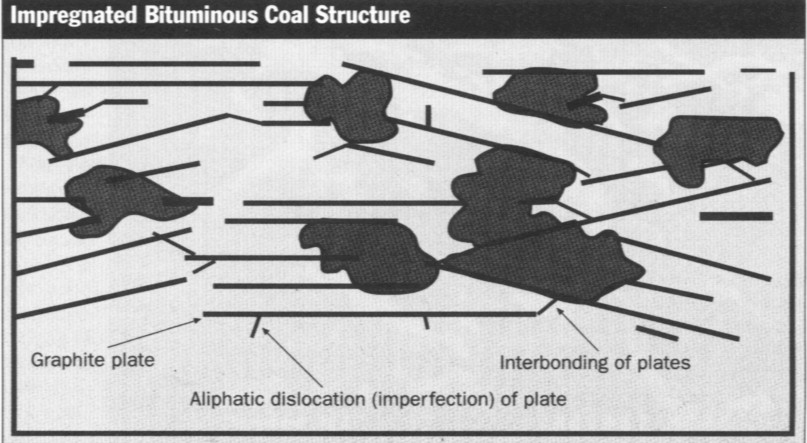

Activated carbon impregnated with sodium

hydroxide (NAOH) or potassium hydroxide (KOH) is another carbon form used to

treat odorous air (see Figure, Impregnated Bituminous Coal Structure).

The impregnation promotes a chemical reaction with adsorbed H2S,

enhancing the carbon's capacity for removing sulfides. In addition to the

impregnants's action, physical adsorption helps remove volatile and odorous

organic compounds and H2S from the air. However, the impregnant

reduces the carbon's adsorption capacity for these compounds, because it

takes up space on the activated carbon, blocking some of the adsorption

pores. In the presence of oxygen, NaOH- or KOH-impregnated activated carbon

undergoes and exothermic reaction (C + O2 ---> CO2)

that can heat the carbon to dangerously high temperatures, causing bed fires

if there is insufficient air flow to dissipate the heat. This risk is

increased by the low ignition temperatures of most impregnated carbons. Both

NaOH-impregnated bituminous coal and KOH-impregnated coconut-activated

carbons ignite somewhere between 200oC and 225oC.

Non-impregnated activated carbons ignite between 380oC and 425oC.

As with standard activated carbon, facilities

can regenerate impregnated carbons to restore their capacity for H2S

removal. To do this, carbon beds are soaked and washed with NaOH or KOH to

remove the sulfur that is produced when S2S reacts with the

impregnant. This also removes a limited amount of adsorbed odorous organic

compounds from the activated carbon.

Impregnated carbons must be removed and

replaced when they cease to adsorb odorous compounds and can no longer be

chemically regenerated. Unlike their non-impregnated counterparts,

impregnated carbons cannot be thermally regenerated because the impregnant

and the adsorbed sulfur interfere with the thermal reactivation process. The

sulfur causes excess sulfur dioxide, a pollutant that violates air quality

standards, and the sodium or potassium impregnant creates catalytic

reactions that destroy the activated carbon. Regeneration with NaOH and KOH

also is a problem because it requires large quantities of the hazardous

chemicals. Exhausted impregnated carbons normally require landfill disposal.

The peroxide solution in these beakers

illustrates the catalytic energy of an enhanced granular activated carbon

(foreground) against a traditional type of carbon (background)

Density the Key

Last year, Calgon Carbon Corp. introduced a

new catalytic/adsorptive carbon for treating municipal wastewater odors.

Centaur™ HSV is a bituminous, granular activated carbon with enhanced

catalytic activity. In many ways similar to traditional bituminous activated

carbons, this version's pores are finer (more of the graphitic plates are

closer together), giving it a higher density.

Because it is not chemically impregnated,

catalytic carbon can remove more volatile and odorous organic compounds. It

adsorbs more H2S because its catalytic sites promote a reaction

between H2S and oxygen from the odorous air stream. More than 90%

of the H2S reacts to form hydrogen sulfate. Only a small amount

goes to elemental sulfur. These products remain on the catalytic carbon

until it is exhausted and ready for regeneration.

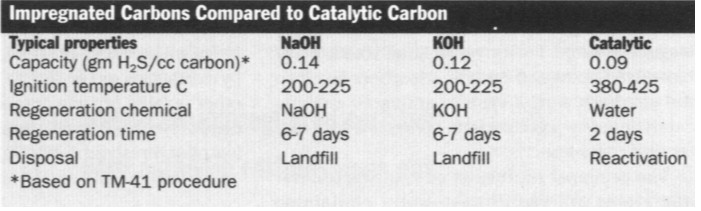

These reactions increase the H2S-removal

capacity from approximately 0.02 gms H2S/cc carbon to 0.09 gms H2S/cc

carbon or greater. Catalytic carbon approaches the H2S-removal

capacity of impregnated products, which is typically between 0.12 and 0.14

gms H2S/cc carbon (see Table, Impregnated Carbons Compared to

Catalytic Carbon).

Because catalytic/adsorptive carbon is not

impregnated with NaOH or KOH, its ignition temperature is comparable to that

of any bituminous activated carbon, 380oC to 425oC.

Because there is no impregnant to cause and exothermic reaction, the product

does not "heat up" like chemically impregnated carbons and is less

likely to cause bed fires.

Once catalytic/adsorptive carbon has reached

its capacity for H2S adsorption, it is regenerated with water

while in the adsorber column. The bed can be backwashed by filling the

adsorber with water and allowing it to soak for approximately one hour.

During this time, the water penetrates the pores of the activated carbon,

dissolving the reaction products. More than 90% of the products of the H2S-removal

reaction on catalytic carbon are sulfuric acids and trace amounts of

sulfurous acids, both of which are water soluble. After the water is

drained, the procedure is repeated six to 12 times to complete the

regeneration.

The solution from the first two washes of

water regeneration are acidic and require careful disposal. Normally, a

facility can drain them back into untreated wastewater, providing this is

done slowly enough to prevent changing the water's pH. After the first

two washes, the solutions can be drained as rapidly as desired, because only

trace amounts of acid remain. When regeneration is complete, the activated

carbon is dried by blowing air through the carbon adsorber for approximately

12 hours, after which time the adsorber is reinstalled.

Catalytic/adsorptive carbon can be water

regenerated until organic loading exhausts the carbon's adsorption capacity.

The volatile and odorous organics - and to some degree the unreacted sulfur

- slowly reduce access to the graphitic plates housing the catalytic sites.

When catalytic carbon loses its adsorption

capacity, it must be removed from the adsorber and be thermally regenerated.

Prior to thermal regeneration, the facility must remove any sulfur compounds

with water. The remaining volatile and odorous organic compounds typically

do not interfere with thermal regeneration. The reactivation process for

catalytic carbon is similar to that of non-impregnated carbons. When

regeneration is complete, the original catalytic sites are restored and the

catalytic carbon functions like a virgin product.

System Design

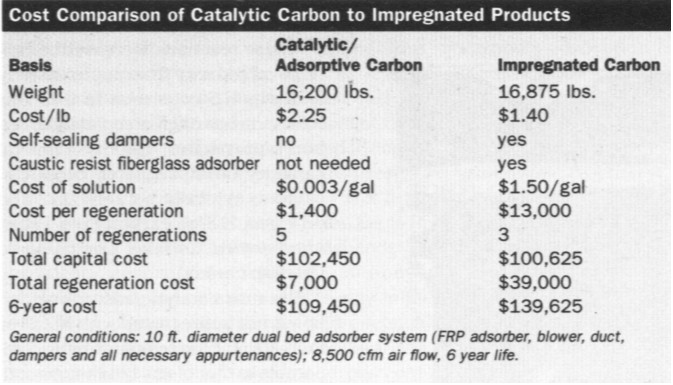

Because catalytic carbon can be regenerated

repeatedly when used primarily for H2S-removal, many facilities

are considering designs that use higher air flows and exhaust the carbon

more frequently, requiring more frequent regeneration. Working with lower

loadings of H2S-reaction products may eliminate problems

associated with regeneration. In effect, regeneration would be done on the

basis of "working capacity for H2S," which is similar

to industrial applications of activated carbon regeneration, such as solvent

recovery. Replacing impregnated carbons with catalytic carbons does not

require physical changes to the system because the impregnated systems are

designed for regeneration, which accommodates water washing.

It is critical that the air velocity of

activated carbon systems stay within 50 feet per minute (fpm) to 100 fpm.

Exceeding 100 fpm air flow fluidizes the activated carbon bed. All systems

use 4x6 U.S.-sieve-series-sized activated carbon to minimize pressure drop,

which lowers capital and operating costs.

Laboratory and field tests indicate that

between 50 fpm and 100 fpm, the mass transfer zone to remove H2S

and volatile and odorous organic compounds is approximately 4-6 in. Beds as

deep as 36 in. promote more efficient use of the activated carbon, because

exiting odourous gases completely exhaust a higher percentage of the carbon

bed. For example, a 12-in. bed will exhaust approximately 75% of the carbon

at breakthrough, because 6 in. of the bed contains the transfer zone, which

is only partially exhausted. A deeper, 36-in. bed would exhaust 92% of the

carbon, a much more efficient use of the product. Hydrogen sulfide removal

applications are most efficient when the relative humidity does not exceed

80%.

Larger, granular activated carbon systems

used in municipal odor control typically are constructed of fiberglass,

because of the corrosive nature of odorous emissions. Smaller package

systems often are made of high-density polyethylene.

Because all activated carbon adsorption

systems have similar adsorber designs, capital costs for catalytic and

impregnated systems are approximately the same. However, impregnated carbon

systems require self-sealing dampers that prevent air from passing through

the carbon adsorber when the system is shut down. Failure to seal the air

causes oxidation, which heats the carbon and can cause bed fires.

Non-impregnated systems use a simple damper to control air flow. Although

catalytic/adsorptive carbon initially costs more than its impregnated

counterpart, the savings from eliminating self-sealing dampers and caustic

resistant fiberglass offsets this capital difference. In the long run,

catalytic systems are cheaper to operate, because they save time and labor,

and require no chemicals.

Gary R. Van Stone is a business

director and

Daniel R. Brooks is market specialist with

Calgon Carbon Corp. in Pittsburgh, PA.

Reprinted from WATER

ENVIRONMENT & TECHNOLOGY, February, 1996

|