|

Adsorption System Treating Contaminated Water |

|||||||||||||||

|

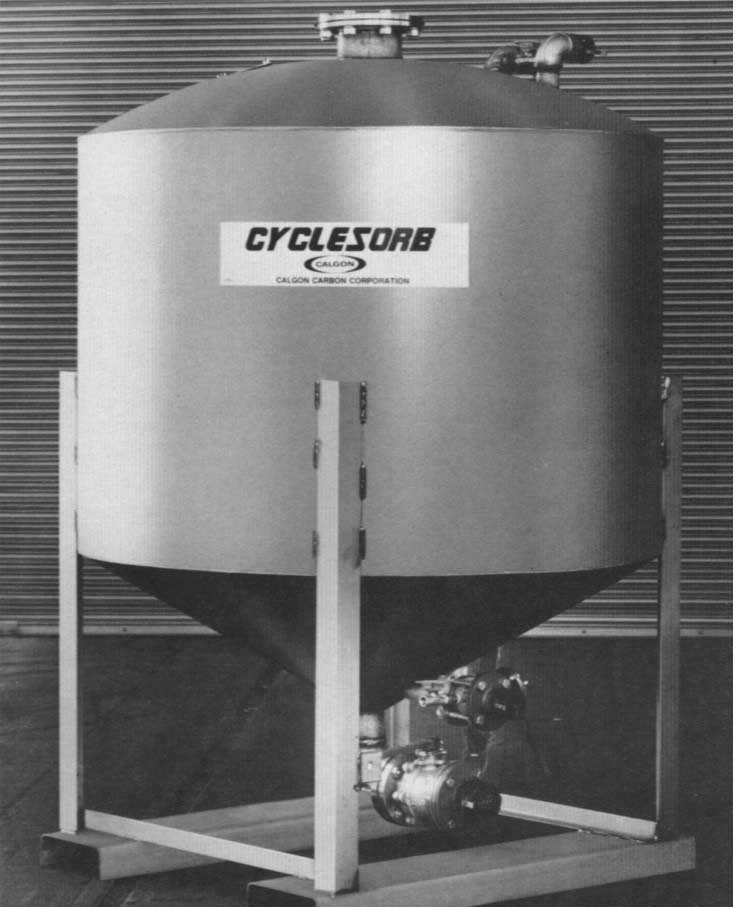

By John D.McManus, Calgon Carbon Canada, Inc. Adsorption system is successfully treating water contaminated from an underground storage tank. During the spring of 1989, the owners of a combined bulk and gasoline service station in Brampton, Ontario discovered leaks from one of the site's underground storage tanks and from a section of piping supplying the above-ground tanks. Diesel fuel and gasoline were migrating into groundwater as well as escaping into storm sewers and contaminating a nearby creek. Company officials estimated that more than 46.500 litres of free diesel product had leaked from the corroded tank and piping. Emergency response Recognizing a need to take corrective action on an emergency basis, the owners retained the Environmental Division of Monenco Consultants Ltd. located in Mississauga, Ontario. (Effective August 1, 1992, Monenco's Environmental Division is called HBT Agra.) Working with a local contractor, Monenco initiated a remediation program designed to contain the movement of contaminants on-site. Containment trenches were installed and the water table was lowered to prevent free product from escaping the site. Several recovery wells were drilled and installed. By the fall of 1989, the recovery wells began operation, continuously pumping contaminated groundwater into tanker trucks. Every day, more than 16,000 litres of contaminated water was trucked off-site for treatment at a private facility. While the trucking of water off-site met emergency response objectives of the owner, the Ontario Ministry of Environment (MOE) and the Peel Region local regulatory agency, it also proved to be quite expensive. At a disposal cost of 23 cents per litre, this remediation approach cost the owner more than $ 24,000 per month. Early in 1990, the owner asked Monenco to investigate other alternatives that would be more cost-effective for the estimated six- to eight-year groundwater cleanup project. Alternative treatments The company seriously considered three options - land-farming bioremediation techniques, air stripping, and carbon adsorption. Bioremediation was rejected because of the close proximity of residential areas and likely air emissions of dust and odors, and because of site space limitations and lengthy treatment time required. Air stripping was eliminated for the following reasons: (1) strippers emit volatile compounds that require additional treatment steps, and (2) it could take one year or more to obtain all required approvals from the Ministry of Environment. The "pump" and "treat" approach, utilizing granular activated carbon to adsorb and remove hydrocarbons, was selected as the best solution. Carbon adsorption chosen A low-flow carbon treatment system - specifically, the Cyclesorb Adsorption Service offered by Calgon Carbon Corporation - was installed at the service station site during the summer of 1990. Monenco had previously used this remediation approach - and met all treatment objectives - at another client's site. At Brampton, two Cyclesorb adsorbers were installed for operation in series; ahead of them, a sand filter was installed to protect the carbon from potential intrusion of sediment from the recovery well. Each Cyclesorb adsorber contained 2,000 pounds of virgin Filtrasorb 400 carbon designed for efficient removal of dissolved organic contaminants. Five feet in diameter and just over seven feet in height, the stainless steel units were easy to install. In operation, water is pumped at 20 gallons per minutes from the recovery wells through a sand filter. Next it enters the top of the first adsorption unit, flows through the carbon beds in units 1 and 2, then is collected by a screened outlet and exits at the side of the second unit's coned bottom section. Treatment by this activated carbon system is successfully removing dissolved fuel components prior to sanitary sewer discharge; effluent concentrations of dissolved hydrocarbons and benzene are being reduced to less than 0.2 ppb. Today, after two years of use, the Cyclesorb Adsorption Service has provided the following benefits at Brampton:

Table 1

Now that the regulatory authorities are comfortable with the way the carbon system works, they have allowed Monenco to reduce sampling frequency procedures to a quarterly basis. Previously, Menenco was required to submit analytical results on a monthly basis. Contaminants of most concern are benzene, toluene, ethylbenzene and xylene. (BTEX). Carbon system influent/effluent data is developed using sophisticated GCMS instrumentation at Monenco's in-house analytical laboratory in Mississauga (just 22 miles south of this service station site). In March of this year, Monenco completed a major upgrading on this groundwater cleanup project. Everything was done on a "rush" basis in 1989 when the problem was first discovered. Over time, Monenco engineers and hydro-geologists determined that recovery trenches were not graded as deeply or as extensively as they should have been. To improve containment and treatment, the most recent changes involved: (1) regrading of trenches to assure that no water and no contaminants escape from the site, (2) drilling and installing two new recovery wells, (3) relocating the existing computerized alarm system connected to recovery well pumps and treatment system flow lines, and (4) physically repositioning the treatment equipment inside a new building. Inside the building, treatment processes now include oil/water separation, sand filtration and carbon adsorption.

Calgon Carbon's small Cyclesorb units proved an ideal choice to Monenco for cleanup of low flow contaminants in groundwater at a service station in Brampton, Ontario. Leaking underground storage tanks have gained recognition as a serious environmental issue. Carbon Adsorption systems, small and large, are popular choice for the pump and treat technique of contaminant removal. Summary The U.S.Environmental Protection Agency estimates that 30 percent of the nearly 2 million U.S. underground storage tanks are leaking. Monenco engineers/project managers have not seen any similar estimates from Canadian authorities, but guess with relative certainty that aging steel underground storage tanks in Canada are probably leaking to the same degree as those in the U.S. At the Brampton service station cleanup project, the low flow carbon system met several objectives set by Monenco and its client. It removed BTEX, helped meet strict effluent limitations, and allowed for effluent discharge to a nearby sewer. Overall, the equipment is performing well, was simple to install, is easy to operate, and is reasonable in cost (particularly as compared to the initial option of off-site trucking ). The Calgon Cyclesorb Service was also attractive because, when needed in the future, it will provide safe, off-site reactivation of spent carbon.

Reprinted from Canadian Environmental Protection, Volume 5, Number 1, January/February 1993 |

|||||||||||||||