| This case study was prepared by the China Canada Cooperation Project in Cleaner Production |

Picking

Low-hanging Fruit:

The Strategic Role of Cleaner Production in

China

Mark Osterman, LL.L.

CEA

Senior Project Manager, Environmental

Management

SNCw LAVALIN International Inc. 455 Rene-Levesque Blvd.

West

Tel: (514) 393-1000 Fax: (514) 393-9540 e-mail: ostem@snc-lavalin.com

Montreal,

Quebec, Canada

The purpose of this presentation is to present the China-Canada Co-operation Project in Cleaner Production and to illustrate, using two demonstration projects, how Cleaner Production can play a strategic role in helping State Owned Enterprises meet both environmental and economic objectives.

The project has been underway for a little more than two years, now, and this is a most opportune time and place to present some concrete results and successes achieved through hard work by a joint Chinese-Canadian team of environmental specialists. First, the project will be briefly presented, then preliminary results from the demonstration projects will be used to demonstrate that Cleaner Production really does represent "opportunity in times of change", as is the theme of the Annual General Meeting. In fact there are times when the economic benefits of Cleaner Production appear so large, that one wonders the project is an environmental or economic project.

The China-Canada Co-operation Project in Cleaner Production is an excellent example of CIDA's support for Cleaner Production in China. A consortium consisting of three leading Canadian companies (Pricewaterhouse Coopers; SNC LAVALIN and ESSA Technologies) is implementing this five year, ten million dollar (CDN) project. Our Chinese partners are the State Economic and Trade Commission (SETC) and the State Environmental Protection Administration (SEPA) as well as other state industrial bureaux. The co-operation between SETC, a ministry having a key economic mandate, and SEPA, the environment ministry is one of the keys to success in Cleaner Production. The project began in 1996.

The targeted sectors of the project are pulp and paper, fertiliser (ammonia-urea) products, fermentation and dye stuffs.

The project has 4 main work components:

-

Policy development;

-

Implementing Cleaner Production solutions and technologies;

-

Cleaner Production information systems; and

-

Training.

It is not necessary here to elaborate on the environmental problems in China. These are, in general terms, well known and other speakers on this panel will address them. Nor is it necessary to address the economic crisis which is shaking the world, or deal with the subject of China’s economy in transition. These matters are being dealt with by others far more knowledgeable than the author, during this AGM.

Instead, this paper presents the project, the difficulties successfully overcome, and the very positive results that have been collectively achieved. From our experience to date, there are some interesting, and indeed encouraging lessons to be learned.

First, some background on Cleaner Production. In Canada the term "pollution prevention" is used to mean the same thing as Cleaner Production here in China. These terms refer to the use of technology, processes and management systems to avoid, in the first place, the creation of pollution, or to minimise pollution, in order to avoid having to treat effluents and emissions in what is called "end of pipe" mode. Cleaner Production is thus the efficient use of resources, producing the same, better or more, with less: less raw materials, less energy, less impact on the environment.

|

|

|

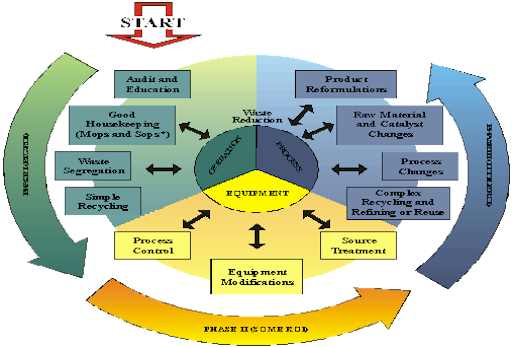

Figure 1: A hierarchy of Cleaner Production solutions

based on Return on Investment enables |

In an economy which has traditionally placed a heavy emphasis on production capacity and quotas instead of production efficiency one can see that Cleaner Production, when explained in economic as well as environmental terms, can be an "opportunity in times of change". The opportunity comes from using an environmental imperative as a motor to improve the efficiency of industry, and the promise of more profitable factories to improve the quality of the environment. In the context of Cleaner Production in China, there is an expression in environmental management which is most apt. It is "picking the low-hanging fruit", which simply means doing the easy stuff first. That which is easy to implement, not costly, and which provides big returns or rewards.

A methodology has been developed which places all Cleaner Production initiatives in a hierarchy based on return on investment (see figure 1). The high ROI and medium ROI initiatives represent the low-hanging fruit. As you will see from the experience to date, in China these have been most plentiful and rewarding.

Indeed, our demonstration projects clearly and dramatically illustrate that the implementation of Cleaner Production can have a significant, and possibly profound impact on the bottom line of a State Owned Enterprise.

First, a glimpse of how the project is building the capacity for Cleaner Production in China.

Chinese policy makers have seen in action a wide variety of different approaches being adopted in Canada by the different levels of government (national, provincial, and municipal). On a recent study tour they learned first hand about revisions being proposed in the Canadian Environmental Protection Act, about multi-stakeholder programs for cleaning up and protecting Canadian rivers, and how industry and other stakeholders become involved in policy development.

Some of the key lessons learned include:

-

that sustainable Cleaner Production is not achieved through a turn key project that delivers a state of the art facility but rather through working with Chinese agencies, institutions and industries to increase their capacity to implement Cleaner Production themselves;

-

that assistance must be provided in ways that allows localised solutions to emerge: sustainable Cleaner Production in China will not necessarily use the same processes and techniques as Cleaner Production in Canada. There can be no cookie-cutter approach to implementing CP: each factory is different;

-

that government must set the environmental objectives and then let industry use its creativity to find the most efficient way to meet them.

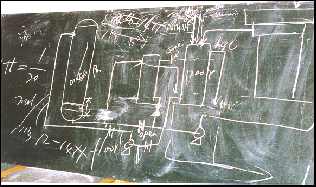

|

|

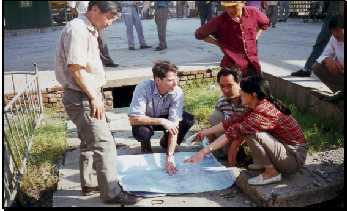

|

Figure 2: Cleaner Production audits always begin with basic data gathering. Here the team is recreating waste water sewer plans in order to then measure the waste water flow from each process unit. |

Our Chinese counterparts have been very interested in learning more about Canada's great success in "partnering" where governments, industry, Environmental NGOs, and other stakeholders all work together to achieve our environmental goals in Canada. They have been intrigued to learn about the St. Lawrence and Fraser River Actions Plans, the national and provincial roundtables on economy and the environment, information and training Centres like the Great Lakes Pollution Prevention Centre, and the numerous advisory groups that all contribute to implementing Cleaner Production in Canada. They have also been very interested in the role of industrial associations like Canadian Pulp and Paper Association, NGOs such as Pollution Probe, and the Canadian Council of Ministers of the Environment. Our success in forming productive partnerships to address environmental problems is one area in which Canadians are world leaders.

Second, Technical personnel are learning how to do Cleaner Production audits and identify Cleaner Production solutions for their factory. Solutions focus on minimising water consumption, in using raw materials and energy efficiently, and recycling materials and products which are in various waste streams.

Also, Production workers are being trained to implement low cost and no cost Cleaner Production solutions related to good housekeeping, standard operating procedures, minimum operating standards and careful and safe management and handling of raw materials and substances.

Here, the key lessons are that there are lots of low-hanging fruit to be picked. By mobilising all employees in an organisation, it is possible to quickly achieve important results and develop a momentum for change in factories. Interestingly, the cycle of implementation of Cleaner Production does not end with the first low-hanging fruit that are picked. In fact, the first low-hanging fruit provide the training ground and act as an encouragement for management and employees to use the methodology over and over again. As sophistication increases, new low-hanging fruit are constantly being discovered. In essence, a new management paradigm is being created.

Each and every challenge to implementing Cleaner Production can be overcome with great success, as will be seen from the case studies. These challenges, for a joint Sino-Canadian team, are the following:

-

theory of CP implementation versus the practice and reality of doing it in factories;

-

language barriers and terminology;

-

differences in approaches and working methods between Chinese and Canadians;

-

differences in technologies between China and Canada;

-

differences in environmental objectives and standards between China and Canada;

-

the challenges of an economy in transition in China;

|

|

|

|

Figure 3: Occasional interpretation problems: |

|

|

Figure 4: .......cooling towers. |

Last but not least, Information specialists are learning how to develop and maintain the various information systems that are needed to keep all of the parts working in harmony with each other. In this "wired" age, they are also learning how to use the Internet to search for solutions to their problems. In so doing, they learn to tap into the expertise of workers from around the world to achieve more efficient operations and hence competitive enterprises. Information systems are a vital part of Cleaner Production. We have a Web site, www.chinacp.com, developed in Canada and presently being transferred to Chinese management at SETC. This Web site will eventually be a key component in the CP information dissemination strategy, at the beginning for the four industrial sectors targeted by this project, and hopefully, for additional sectors as time passes.

One important feature of our project is using two demonstration projects, both in the Huai River Basin in Anhui Province, to identify and implement Cleaner Production solutions that will work in a specific context. These are at the following State-Owned Enterprises:

-

Anhui Wanzhi Paper-Making Co. Ltd. (Huainan City, Anhui Province)

-

Fuyang Chemical General Works (Fuyang City, Anhui Province)

Joint Cleaner Production audits involving Canadian and Chinese experts have been conducted with the full support and involvement of the plant's managers, technicians and workers. A number of no to low cost solutions identified during the audits have been implemented immediately by the plants and significant environmental and economic benefits are already apparent. In the coming months, jointly identified and designed cost efficient medium cost solutions (in the 2 to 3 million Renmibi range) resulting in additional important pollution reduction will be implemented. It is estimated that the combined no to medium cost solutions have the potential of generating internal annual savings of about 6-8% of the production costs and reducing pollution emissions by 50-75%, which is quite significant.

The demonstration projects are proving invaluable for several reasons:

-

they provide a mechanism for local solutions to emerge and not waiting for a central authority to provide a universally applied, cookie cutter answer;

-

they underline the importance of developing problem solving and innovation, rather than depending exclusively on technical expertise from a central authority;

-

they focus attention on the facility as a whole rather than on the end of the pipe and put each Cleaner Production solution into a broader context where well-informed choices can be made;

-

they allow people to learn by doing and to acquire hands on experience;

-

they are an effective way to demonstrate to other plants that significant pollution reduction can be achieved through affordable low to medium cost solutions which can be amortised within one year.

|

|

|

Figure 5: Process flow diagrams often have to be developed from scratch from the blackboard.... |

This last reason is extremely important to CIDA since our co-operation project will NOT achieve its objectives unless the findings and lessons from the demonstration plants are replicated in a number of enterprises. Our Chinese counterparts will have a key role to play to convince other enterprises to implement similar Cleaner Production solutions.

In fact, given the high rates of return on investments in Cleaner Production, as seen in the demonstration factories, it could be argued that Cleaner Production could play a strategic role in the current Chinese Government's reforms to achieve economic self-sufficiency for State Owned Enterprises.

|

|

|

Figure 6: ....to the finished product using Computer Assisted Design (CAD) |

The Fuyang Chemical General Works claims to have, in less than one year, realised an increase in production capacity of approximately three percent, just by implementing various good housekeeping measures identified during the audit process. These included such simple activities as investing some time and energy in maintaining the piping and valves. The implementation, over the next six months, of two medium cost solutions, financed by Canada, should also be amortised within a year and lead to literally millions of RMB in annual benefits for the factory. The two principal pollutants, ammonia and sulphur, will be reduced by more than half. Where do the financial benefits come from? The ammonia and sulphur, which previously went out with the waste water, will now be recovered, re-used and sold in products. Added on to the three percent increase in capacity from the good housekeeping measures, is an additional three percent productivity gain from the two medium cost solutions. All of these gains are essentially achieved at no increase in production costs.

|

|

|

Figure 7: At Fuyang, good housekeeping begins with paint and proper labels on process equipment. |

At Anhui Paper, twenty nine no cost and low cost Cleaner Production solutions are gradually being implemented. The economic and environmental analyses are presently underway, but already amazing financial benefits have been identified. These will be derived from savings in water consumption and recovery of process chemicals and fibres which, instead of going into the river, will be made into paper. Essentially, the problem in the paper industry is excessive consumption of water, poor recovery of process chemicals, and excessive loss of fibre. All of the above have the side effect of consuming far too much energy.

|

|

|

Figure 8: De-dusting operations at Anhui Paper. Excessive use of clean water which is not recycled can be easily corrected. Estimated savings: 60,000 cubic meters of water per year and 360 tons of suspended solids. |

The ROI for implementation of Anhui Paper Mill’s low cost solutions is presently being calculated. To date, the costs of 22 solutions are know, as well as the benefits for nine. If all 22 solutions were implemented, and only the nine provided benefits, the net result would be over 500,000 RMB savings per year. The other solutions, once the cost analysis is complete, should enable the Mill to save up to three million RMB per year. Added to this are six million RMB in savings realised by switching to cleaner, better performing coal. When the savings resulting from the medium cost solutions are added on, this becomes truly impressive for a mill which produced only 35,000 tons of paper per year. As for the environmental savings, it is anticipated that the reduced water and energy consumption, and reduced pollutant loading, will be enough to offset a threefold increase in pulp production to eventually be derived from World Bank financed expansion projects. This could possibly make the mill self sufficient in pulp production, thus ending the costly importation of foreign bleached pulp. These savings on pulp purchases are not, of course, factored into the above ROI analysis! It should be noted that while the focus of the project is on water pollution, by reducing water consumption less power will be needed to pump excessive water through the plant. As power is generated by coal fired boilers, this will result in a significant reduction in air pollutant emissions.

Both SOEs will be more efficient, competitive firms when this process is complete, and less polluting ones, as well.

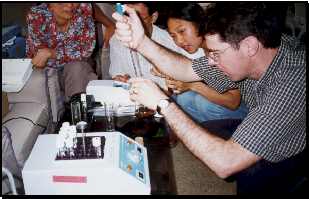

What about air pollution?

|

|

|

Figure 9: Training in the use of pollution measuring equipment ensures that polluting processes are properly monitored. |

The efforts of the project have been concentrated on waste water, in part because in the industries covered by the project, it was in this sector that the biggest gains could be made and in part because of the focus on cleaning up the Huai River basin. One of the strongest lessons learned to date is regarding the importance of focusing on efficiency, instead of production capacity. It has been demonstrated that a paradigm shift to efficiency, or Cleaner Production, could reap huge benefits when water pollution is the target.

Given that in China, the prime source of energy is coal fired boilers, a significant reduction in water consumption tends to lead to a significant reduction in power consumption, which can only be beneficial for air quality.

|

|

|

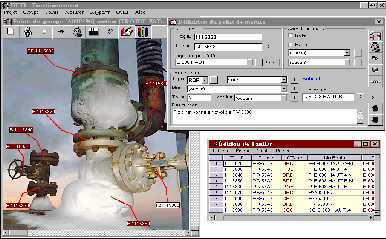

Figure 10: DEFI software provides a cost effective way to maintain the tens of thousands of joints and seals in a typical chemical plant. |

In addition, managers are beginning to realise that the cost of coal must be measured not only by the purchase price per ton, but more importantly in terms of the value of the coal as an energy source. Thus, while "cheap" coal might cost less per ton, Anhui Paper Mill has shifted to coal which is more expensive to buy, but which provides more energy output with less ash and sulphur. The net results are claimed to be savings of six million RMB per year, with better environmental quality to boot.

Transposing the efficiency lesson to the fine chemicals and petrochemical industry, it is expected that huge gains could be made regarding air pollution.

Chemical plants consist of a large number of process units and tanks connected by a vast array of piping, pumps, valves and other equipment. Each block valve, control valve, pump seal, compressor seal, pressure relief valve and all equipment and piping flanges and connectors, as well as sampling connections, are potential sources of leaks, called fugitive emissions. When potential sources of leaks are numbered in the thousands, or tens of thousands as is the case in a typical chemical plant, even a low percentage of fugitive emission sources can amount to a considerable loss of raw materials, intermediary, or final products. When these products have high value, the losses can amount to many hundreds of thousands dollars per year. The large number of potential leak sources makes the logistics of maintenance a potentially difficult, and hence costly, management problem.

|

|

|

Figure 11: DEFI is proprietary software developed by SNC-LAVALIN, to manage fugitive emissions for the chemical industry. |

The environmental cost of fugitive emissions is also high. The gasses which are emitted from chemical plants are important contributors to urban smog, to the depletion of the ozone layer and to global warming. In addition, the compounds themselves are often toxic and some are known carcinogens.

By their physical location, fugitive emissions do not disperse well. Contrary to normal emissions from a chimney, there is a negligible dispersion effect. This results in ambient air quality problems within the plant walls as well as the creation of urban smog. Furthermore, in plants which have unusually high fugitive emissions from process equipment, there is a potential for occupational health and safety problems.

|

|

|

Figure 12: A technician uses a portable analyzer to measure fugitive emissions of process gasses. |

From experience, the amount of maintenance and skill of maintenance and other operators are key variables which impact on the actual leak rate. Typically, the percentages of potential sources which are actually leaking vary from 8% to 10% in North American plants. There is no reason to suggest that the rate would be lower in Chinese plants and it is suspected based on work experience in Cleaner Production in Chinese factories that the rate would actually be higher.

A good housekeeping program can reduce leak rates to below 2%. This is achieved through simple maintenance activities, costing virtually nothing. The problem, in chemical and petrochemical plants, is that there are potentially hundreds of thousands of leak sources, thus creating a logistics nightmare.

|

|

|

Figure 13: DEFI produces a database with digital photographs of equipment, identifying leaks (volume and cost) and the specifications of leaking equipment. |

This is solved using specialised computer software which tracks, using a sophisticated database and portable sensors, the actual leak rate and sources and provides maintenance operators with routes to follow within the plant to correct the problems.

One such software is called DEFI™ and was developed by SNCw LAVALIN. In the company’s experience implementing DEFI™ in North America and Europe, its clients have found that the ROI is less than one year. As manpower is the largest single cost of implementing fugitive emissions programs, and as the gasses which are lost are commodities which trade at world market prices, it is anticipated that important economic and air quality benefits can be derived from implementing this technology in China.

Conclusion

To conclude, picking the low-hanging fruit represents a tremendous opportunity in times of change. No enterprise can afford to stand idly by while its competitors implement Cleaner Production. Cleaner Production in China is an excellent illustration of the link between environment and economy and is a vital step towards sustainable development. In a country beset with significant environmental problems, the economic benefits of Cleaner Production provide a powerful incentive to factory managers, themselves struggling to deal with serious financial and restructuring problems.

|

Anhui Paper’s analysis of economic benefits of low cost CP options (analysis incomplete, work in progress). When all solutions are implemented, annual benefits are expected to be immense. | ||

|

|

Range RMB |

RMB |

|

Capital cost (22 solutions) |

50 to 200,000 |

883 102 |

|

Benefits derived (9 solutions) |

18,000 to 400,000 |

1 460 000 |

|

Net savings (first 9 solutions) |

|

576 898 |

|

Energy savings per year |

|

6 000 000 |

|

Total yearly savings (9 of 22 solutions) |

|

6 576 898 |

Each Cleaner Production solution which is successfully implemented ramps up the enterprise to new levels of productivity. This frees up working capital for more costly Cleaner Production solutions, in a spiral of continual improvement. It makes it easier for enterprises to deal with the restructuring problems which they have. Problems become easier to manage when such improvements are made to the bottom line. The environment is also a big beneficiary of Cleaner Production initiatives, as volumes of effluent decrease and less waste is generated through greater efficiency.

Cleaner Production, by itself, is not the solution to China’s environmental problems. In addition to implementing Cleaner Production, China will have to significantly toughen its environmental standards, and its environmental enforcement. But Cleaner Production will enable SOEs to discover that at times, there can be a win-win situation, and that they can use principles and methodologies of sound environmental management to improve their bottom line. This new paradigm will play a strategic role in the development of Chinese industry for many years to come.

See also:

©SETC 2000-2002