| Overview:

|

The thermophilic biological

process (TBP) is used to treat pink water, which is explosive-laden wastewater

originating from two munition functions: load, assemble, and pack (LAP)

and demilitarization (DEMIL). TBP utilizes granular activated carbon (GAC)

to adsorb the explosives from the wastewater, followed by base hydrolysis

and thermophilic (microbiological) regeneration of the GAC. The treated

wastewater is sent to a wastewater treatment plant. Although additional

research is required, the TBP process potentially could be adapted to treat

explosives-contaminated groundwater and soils.

TBP is a modification of the Army's present

method of GAC regeneration. Currently, Army Ammunition Plants (AAPs) meet

pink water discharge requirements by removing the contaminants using GAC

adsorption systems. The explosive-laden GAC is either regenerated for

reuse or incinerated for disposal. Under the present method, regeneration

often does not achieve Army requirements, and the GAC must be disposed

as a hazardous waste.

The process begins with the pink water flowing

into the GAC adsorption system. The explosive contaminants are first adsorbed

onto the GAC, which has demonstrated a high affinity and capacity for

these nitrobody compounds. After an adsorption cycle, flow through the

GAC column stops and recirculation of a regeneration solution starts.

The GAC column is first heated to 80°C (176°F) for base (caustic)

hydrolysis, and then cooled to 55°C (131°F) for thermophilic regeneration,

inoculated with explosives-degrading organisms, and aerated. The column

becomes a bioreactor. Thus, explosive compounds, concentrated by the previous

adsorption step, are depleted, and the GAC in the column is regenerated.

The bioreactor fluid, containing natural organisms and enzyme systems,

passes to the industrial wastewater treatment plant. In the last step,

the regenerated GAC column cools and is placed on stand-by.

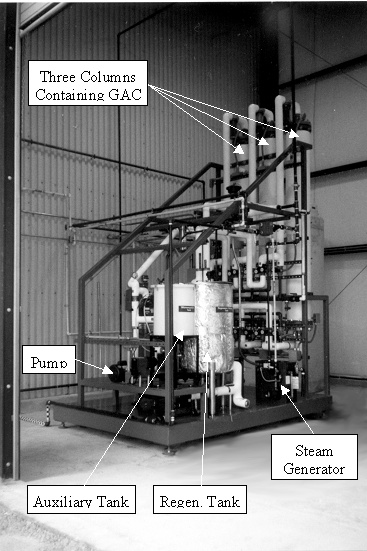

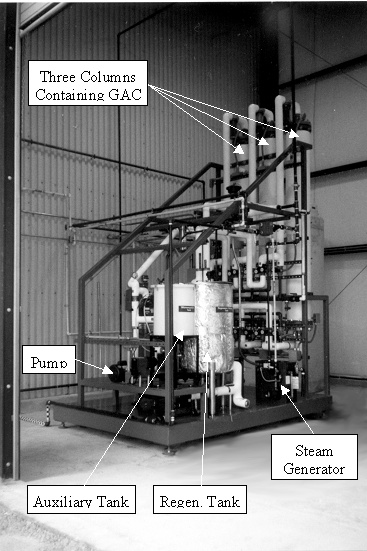

A TBP pilot-scale plant was installed and

operated at the Milan AAP (MLAAP), Milan, Tennessee, prior to being transitioned

to the Iowa AAP (IAAAP), Middletown, Iowa, in February 2001. This plant

is capable of processing 1.5-2.0 gallons per minute. The TBP skid equipment

is self-contained, and consists of three GAC columns, a regeneration tank,

pumps, air compressor, a chemical injection system, and instrumentation/controls.

Five confirmatory tests were completed at

the MLAAP. Through this demonstration project, the following conclusions

were reached:

- The thermophilic biological process is technically sound.

- Under optimized conditions, this TBP technology degraded over 90%

of the nitrobodies from the loaded GAC. During loading, the discharge

of nitrobodies from the regenerated GAC in the column gave slightly

higher (better) percent removals of nitrobodies compared to that of

loading with virgin GAC.

- The water discharged is non-toxic, according to results from toxicity

testing.

- The TBP is economically viable for a full-scale operating system.

Using spent GAC provided by IAAAP, a loading

and regenerating cycle of three (3) more tests was complete in March 2001.

The results showed a Destruction and Removal Efficiency (DRE) of explosives

from the GAC surface of 99.2, 98.4, and 99.2 percent in the three tests,

respectively.

|

|

Compliance Benefit: |

Pink water by definition

is a Resource Conservation Recovery Act (RCRA) K047 Hazardous Waste due

to the presence of nitrobodies, including 2,4,6 trinitrotoluene (TNT), cyclotrimethylene-trinitramine

(RDX), and cyclotetramethylene-tetranitramine (HMX). The exact composition

of pink water is highly variable and dependent on process materials and

operations. The maximum concentration of dissolved energetic-related pollutants,

in pink water, is 200 parts per million. Statutes also mandate that pink

water be treated prior to disposal.

The U.S. Army required a DRE rate of 80-90

percent or higher. The DRE is the difference in the amount of nitrobodies

on the GAC, before and after regeneration, and is reported as a percentage

of the total loading of nitrobodies on the GAC. The TBP achieved DRE rates

of greater than 90 percent under optimum operating conditions.

The Compliance Benefits listed here are

only meant to be used as a general guideline and are not meant to be strictly

interpreted. Actual Compliance Benefits will vary depending on the factors

involved, e.g., the amount of workload involved.

|

| Materials

Compatibility: |

No materials compatibility

issues were identified.

|

| Safety and Health: |

The technology itself poses

no safety or health risks. However, several contaminants in the pink water

are dangerous, and precautions should be taken. Proper personal protective

equipment is recommended. The personnel in work areas should wear safety

glasses with side-shields and steel-toed safety shoes. Hands should be protected

with nitrile (rubber) gloves when loading the column with pink water and

when handling the microorganisms. Good hygiene (e.g., washing hands with

antibacterial liquid soap after handling the microorganisms) and daily housekeeping

should be practiced. Neither respirators nor special ventilation are required.

Consult your local industrial health specialist

and your local health and safety personnel prior to implementing this

technology.

|

| Benefits: |

- Biodegrades most nitrobodies in explosives-laden wastewater and renders

them nontoxic.

- Regenerates loaded GAC columns, in situ, avoiding the risks and losses

associated with handling and incinerating and/or regenerating the spent

GAC by combustion.

- Can be retrofitted to the existing GAC adsorption systems installed

at most of the AAPs, with only minor modifications.

- Requires less energy than other processes currently in use.

- Commercially available.

|

| Disadvantages:

|

- Capital costs may be significant

|

| Economic

Analysis: |

The following cost elements

compare the use of a conventional GAC adsorption system using GAC once with

a TBP that regenerates the GAC five times.

|

| Assumptions:

|

- Costs were calculated from data obtained from pilot-scale test results.

The TBP retrofit system was scaled up for a 20-gpm system that loads

one carbon bed per week, based on data from the IAAAP. (The pink water

treatment systems at the MLAAP operate at 40- to 80-gpm and are currently

utilized only sparingly. If the MLAAP was fully operational, and if

the pink water treatment system design had specified a flow rate within

the 40-80 gpm range, the cost breakdown for MLAAP's estimated treatment

cost would be proportionately equivalent to results shown below.)

- Five regenerations occurred with the TBP technology.

- Breakdown of the cost categories is shown in the following table.

Table 1. Annual Operating

Costs for Pink Water Treatment Technologies

|

Cost

Category

|

Input

Parameter

|

Unit

Cost

|

Baseline

|

TBP

|

|

Labor

|

changing GAC

|

$44/hr

|

$27,456

|

$4,576

|

|

regeneration

|

---

|

$15,253

|

|

Materials

|

GAC (new, virgin)

|

$1.305/lb

|

$40,716

|

$6,942

|

|

chemicals/microbes

|

various

|

---

|

$9,377

|

|

Utilities

|

electricity

|

$0.054/kWh

|

---

|

$943

|

|

steam

|

$15/1000

lbs.

|

---

|

$650

|

|

water/sewer

|

$5/1000

gal

|

---

|

$347

|

|

Waste Management

|

waste disposal

|

$0.50/lb

|

$31,200

|

$5,200

|

|

drums and liners

|

$71.10/drum

|

$22,183

|

$3,697

|

|

reg. compliance

|

$45/hr

|

$10,395

|

$2,295

|

|

TOTAL

(per year) using new, virgin GAC

|

$131,950

|

$49,285

|

|

| Capital

Cost: |

The capital cost to retrofit

the TBP technology to an existing 20-gpm system is approximately $230,560.

|

| Operational

Cost: |

Operating costs for GAC TBP

will vary considerable depending upon the process configuration required

for the particular GAC regeneration application. Annual operating costs

for the field-level GAC TBP system were estimated at $49,285, versus $131,950

per year for a conventional GAC process.

|

| Payback

Period: |

The calculated payback period

for investment in the equipment/process is 3.44 years, using a 15-year analysis,

10% discount rate, and a straight line depreciation over a period of 10

years.

|

| Annual

Savings: |

The calculated annual saving

is $82,665 in operating costs, if the TBP is retrofitted to an existing

20-gpm GAC adsorption system.

|

| Economic

Analysis Summary: |

A summary of the financial implications

for retrofitting a GAC TBP system on a conventional GAC process in field-level

activities, which includes annual operating cost benefit and capital investment

required, is shown in Table 2. The 15-year NPV and IRR, as well as the

payback period are also listed in Table 2.

Table 2: Financial Implications

of Retrofitting a Conventional GAC Process with a GAC TBP

|

Category

|

Financial

Analysis Results

|

|

GAC

TBP

|

Conventional

GAC

|

|

|

$49,285

|

$131,950

|

|

Investment Required

|

$230,560 b

|

$0

|

|

Discounted Payback Period (year) a

|

3.44 years

|

N/A

|

|

NPV

a

|

$400,000

|

N/A

|

|

IRR

a

|

35.5%

|

N/A

|

|

a

|

This value was calculated with Pollution Prevention Financial Analysis and Cost Evaluation System (P2/FINANCE). This software is proprietary and copyrighted by Tellus Institute of Boston, Massachusetts. A 15-year analysis, 10% discount rate were assumed, and a straight-line depreciation over 10 years.

|

|

b

|

This number is based on the cost of the equipment, installation, and other fabrication costs. contributing one-time fees related to the process.

|

|

| NSNs:

|

None Identified.

|

| Approving

Authority: |

Approval is controlled locally,

and the technology should be implemented only after engineering approval

has been granted. Major claimant approval is not required.

|

| Points of Contact: |

Dr. Mahmood A. Qazi,

Concurrent Technologies Corporation, 100 CTC Drive, Johnstown, PA

15904, Phone: (814) 269-2726

|

| Vendors:

|

CTC is the sole source of the Thermophilic

Biological Process (TBP) Technology.

Concurrent Technologies Corporation

100 CTC Drive, Johnstown, PA 15904

POC: Mahmood A. Qazi, Ph.D

Phone: (814) 269-2726

Fax: (814) 269-6847

This is a complete list, as there are no

other suppliers of this type of equipment.

|

| Source(s):

|

Concurrent Technologies Corporation.

Pilot-Scale Thermophilic (Biological) Process Final Technical Report.

June 15, 2000. |

| Supplement(s)

to the Data Sheet: |

- Schematic of the GAC Thermophilic Biological Process (TBP) Pilot Plant

- Picture of the TBP Pilot Plant Equipment.

|