Passivation of Stainless

Steel

Getting the properties you paid for...

By Dan

Englebert

Imagineering

Enterprises, Inc.

South Bend, IN

| Get

Information |

Meeting

Tough Specs on a Hot Dip Galvanizing Line

Learn more

about another rustproofing method for steel.

|

| For more

information... |

| on passivation of

stainless steel, contact Imagineering Enterprises, Inc.,

219-287-2941, Fax: 219-287-2970. |

|

| |

|

|

The conversation usually begins like this: "Hey, this is Joe from

Joe's Machine Shop. We have a job in here and the customer wants us

to have some kind of passivate coating something or other. Do you

guys do that? How thick is that stuff? Is that like plating, paint

or what? What color is it? How much tolerance should I allow for

it?" The opening statement usually ends with a phrase like: "I don't

even know why they need it. What is the point of using stainless

steel if you are going to put some kind of coating on it anyway?"

Joe is not the exception. Many machine shops, purchasing agents

and engineers are somewhat in the dark when it comes to the

relationship between corrosion resistant (stainless) steel and

chemical passivation. Even among the finishing community, there is

some disagreement about the theory behind the process of chemical

passivation. Some believe it is effective because it is a cleaning

process. Others credit the enhanced corrosion resistance properties

to the thin, transparent oxide film resulting from chemical

passivation. Regardless, the bottom line is that it works.

Verification tests, including copper sulfate immersion, and

accelerated corrosion tests, such as salt spray, high humidity and

water immersion, undisputedly confirm the effectiveness of chemical

passivation. Advanced material engineers in aerospace, electronics,

medical and similar high-tech industries have used chemical

passivation for years. The applications demand the maximum

performance from components manufactured from corrosion-resistant

steels, and they realize that passivation is one of the most

effective methods of achieving these results.

|

What is passivation?

|

| According to ASTM A380,

passivation is "the removal of exogenous iron or iron

compounds from the surface of stainless steel by means of a

chemical dissolution, most typically by a treatment with an

acid solution that will remove the surface contamination, but

will not significantly affect the stainless steel itself." In

addition, it also describes passivation as "the chemical

treatment of stainless steel with a mild oxidant, such as a

nitric acid solution, for the purpose of enhancing the

spontaneous formation of the protective passive film."

In lay terms, the passivation process removes "free iron"

contamination left behind on the surface of the stainless

steel from machining and fabricating. These contaminants are

potential corrosion sites that result in premature corrosion

and ultimately result in deterioration of the component if not

removed. In addition, the passivation process facilitates the

formation of a thin, transparent oxide film that protects the

stainless steel from selective oxidation (corrosion). So what

is passivation? Is it cleaning? Is it a protective coating? It

is a combination of both. |

|

How is passivation

performed?

|

| The process typically begins

with a thorough cleaning cycle. It removes oils, greases,

forming compounds, lubricants, coolants, cutting fluids and

other undesirable organic and metallic residue left behind

because of fabrication and machining processes. General

degreasing and cleaning can be accomplished many ways,

including vapor degreasing, solvent cleaning and alkaline

soaking.

|

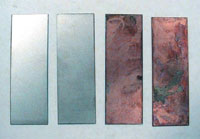

TWO-HOUR salt spray test

per ASTM B-117. With passivation on the left and without

on the right.

|

After removing organic and metallic residues, the parts are

placed into the appropriate passivation solution. Although

there are many variations of passivating solutions, the

overwhelming choice is still the nitric-acid-based solutions.

Recently, there has been substantial research performed to

develop alternative processes and solutions that are more

environmentally friendly, yet equally effective. Although

alternative solutions containing citric acid and other types

of proprietary chemistry are available, they have not been as

widely accepted commercially as nitric-acid-based solutions.

The three major variables that must be considered and

controlled for the passivation process selection are time,

temperature and concentration. Typical immersion times are

between 20 min and two hours. Typical bath temperatures range

between room temperature and 160F. Nitric acid concentration

in the 20 to 50% by volume range is generally specified. Many

specifications include the use of sodium dichromate in the

passivation solution or as a post passivation rinse to aid in

the formation of a chromic oxide film. Careful solution

control, including water purity, ppm of metallic impurities

and chemical maintenance, are crucial for success.

The type of stainless steel determines the most effective

passivation process. Bath selection (time, temperature and

concentration) is a function of the type of alloy processed. A

thorough knowledge of the material types and passivation

processes is paramount to achieving the desired results.

Conversely, improper bath and process selection and/or process

control will produce unacceptable results. In extreme cases,

this can lead to catastrophic failure, including extreme

pitting, etching and/or total dissolution of the entire

component. |

|

Equipment and precautions

|

| Passivation should only be

performed by trained, experienced technicians familiar with

the potential hazards associated with the science. Safety

practices must be fully understood when handling passivation

chemicals. Special boots, gloves, aprons and other safety

equipment must be used. Tanks, heaters and ventilation, as

well as baskets and racks must be appropriately engineered to

perform the process. Iron or steel parts or equipment must

never be introduced to the process, or the results can be

devastating. Furthermore, in order to comply with EPA

requirements, the necessary water and air permits and

treatment capabilities must be in place. The days of

mom-and-pop shops performing passivation in a stone crock in

the back of the shop are gone. |

|

Specifications and verification

testing

|

| There are a few generally

accepted industry specifications available for reference when

choosing a passivation process. They offer time, temperature

and concentration information and subsequent testing

requirements to validate the effectiveness of the process.

Many large corporations have developed internal specifications

to control their unique requirements regarding passivation and

verification testing. Regardless of the situation, it is

usually prudent to reference a proven procedure when

requesting passivation. By referencing a specification, you do

not have to reinvent the wheel. By taking advantage of the

experiences of others, both successes and failures, you can

eliminate much of the guesswork that would otherwise accompany

a new process.

Although recently canceled, the most commonly referenced

industry specifications regarding passivation are Federal

Specification QQ-P-35C, which is now superseded by ASTM A-967

and ASTM A-380. All are well-written, well-defined documents

that provide guidance on the entire process, from

manufacturing to final testing requirements. If you are not

sure what you need, they can be referenced in full or

selectively. The testing requirements can be used or waived,

depending on the individual situation.

One of the most commonly specified verification tests is

the copper sulfate test. Passivated parts are immersed in a

copper sulfate solution for six min, rinsed and visually

examined. Any copper (pink) color indicates the presence of

free iron and the test is considered unacceptable.

Other validation tests include a two-hr salt spray or 24-hr

high-humidity test. These tests are performed by placing

passivated parts in a highly controlled chamber that creates

an accelerated corrosive environment. After subjecting the

test pieces to the corrosive atmosphere for the prescribed

exposure periods, the parts are removed and evaluated.

Although results can be somewhat subjective, ASTM B-117 is an

excellent reference in determining acceptability. It is

important to note that each of the test methods mentioned have

different advantages and limitations. Care should be taken to

select the appropriate test methods based on alloy type and

end-use environment. |

|

Machining and heat treating

techniques

|

| Perhaps the most overlooked

variable in the entire passivation equation is the negative

impact of poor machining and heat treating practices. All too

often, cross contamination introduced during manufacturing

and/or thermal processes leads to unacceptable test results.

The following practices will reduce cross contamination during

manufacturing and increase the chances of successful

passivation and test results.

|

STAINLESS

STEEL parts are supposed

to be

rust-resistant

|

SO HOW does

this happen?

|

Never use grinding wheels, sanding materials or wire

brushes made of iron, iron oxide, steel, zinc or other

undesirable materials that may cause contamination of the

stainless-steel surface.

The use of carbide or other non-metallic tooling is

recommended.

Grinding wheels, sanding wheels and wire brushes that have

been previously used on other metals should not be used on

stainless steel.

Use only clean, unused abrasives such as glass beads or

iron-free silica or alumina sand for abrasive blasting. Never

use steel shot, grit or abrasives that have been used to blast

other materials.

Thorough cleaning prior to any thermal processing is

critical. Stress relieving, annealing, drawing or other

hot-forming processes can actually draw surface contaminants

deeper into the substrate, making them almost impossible to

remove during passivation.

Care should be taken during all thermal processes to avoid

the formation of oxides. Passivation is not designed to remove

discoloration and will not penetrate heavy oxide layers. In

extreme situations, additional pickling and descaling

operations are required prior to passivation to remove the

discoloration. Controlled atmosphere ovens are highly

recommended for all thermal processes to reduce airborne

contamination and prevent oxides from developing.

|

COPPER SULFATE test per

MIL-STD-753. With passivation on left and without on

right.

|

So how do you get the performance you have paid for from

high-dollar stainless steel alloys? It boils down to a basic

understanding that the passivation process is both an art and

a science, and that machining, fabricating and heat treating

practices can substantially affect the corrosion resistance of

the component. Passivation will enhance the corrosion

resistance of stainless steels, but to realize the maximum

performance from these high-tech alloys, all parties involved

with manufacturing must understand their responsibility in

maintaining the integrity of the material throughout the

process. |

References

- ASTM A380 - 96 Standard Practice for Cleaning, Descaling, and

Passivation of Stainless Steel Parts, Equipment, and Systems. ASTM

Committee A-1 on Steel, Stainless Steel, and Related Alloys.

- Fed. Spec. QQ-P-35C October 28, 1988 Passivation Treatments

For Corrosion Resistant Steel. Cancelled April 4, 1997; Superceded

by ASTM A967 – 96.

- ASTM A967 - 96 Standard Specification for Chemical Passivation

Treatments for Stainless Steel Parts. ASTM Committee A-1 on Steel,

Stainless Steel, and Related Alloys.

- ASTM B117 - 95 Standard Practice for Operating Salt Spray

(Fog) Apparatus. ASTM Committee G-1 on Corrosion of

Metals.

| |