AIR

QUALITY RESEARCH AND TECHNOLOGY TRANSFER WHITE PAPER AND RECOMMENDATIONS FOR

CONCENTRATED ANIMAL FEEDING OPERATIONS

by

Confined Livestock Air

Quality Committee of the

USDA Agricultural Air

Quality Task Force

John M. Sweeten (Chair),

Texas A&M University

Larry Erickson, Kansas State

University

Phyllis Woodford, Colorado

Department of Public Health & Environment

Calvin B. Parnell, Texas

A&M University

Kendall Thu, Northern

Illinois University

Tommy Coleman, AAMU - Plant,

Soil, and Animal Sciences

Robert Flocchini, University

of California - Davis

Clinton Reeder, Pendleton,

OR

Jerold R. Master, Arkansas

Pork Producers Association

William Hambleton, Fresno,

CA

George Bluhm,

USDA-NRCS

Dennis Tristao, J. G.

Boswell Company

Adopted

by

USDA Agricultural Air

Quality Task Force

Washington

D.C.

July 19,

2000

Acknowledgements

The

following persons also contributed written material or valuable editorial

suggestions:

·

Dr. Allen Sutton, Purdue

University

·

Dr. Brent W. Auvermann,

Texas A&M University

·

Dr. Lowell Ashbaugh,

University of California - Davis

Table of

Contents

EXECUTIVE

SUMMARY

Introduction

Air

Quality Parameters and Concerns

1. Odors and

Odorants

2. Major Gases of Concern - Ammonia

and Hydrogen Sulfide

3. Particulate Matter --

PM10 and PM2.5

4. Co-Product Gases – CO2,

CH4, etc

Emission

Factors: A Case for Accuracy

1. Significance of Emission

Factors

2. Emission Factors for Cattle

Feedyards and Dairies

3. Errors in the AP-42 Cattle Feedyard

Emission Factor

4. Comparison of Emission Factors

Using a Line Source (TAMU Process)

and ISC Dispersion Modeling

5. PM

Concentrations

6. Recommendations for Correcting

Emission Factors

Human

response and health effects

1. Confined

Animals

2. Employee

Concerns

3. Affected

Public

Current

Policy – Characterization and Assessment

1. Overview

2. Federal

Policies

3. Recent State Policy

Developments

Current

Technologies to Address Odor Problems

1. Approaches: An

Overview

2. Diet Effects on

Odors

3. Manure Treatment for Odor

Control

4. Capture and Treatment of Odorous

Gases

5. Enhanced Dispersion of

Odor

6. Summary of Odor Control

Opportunities

Candidate

Dust (PM) Control Practices

Current

Research Programs to Address Problems

1. General Characterization of Prior

Research

2. Health

Issues/Risks

3. Current Research

Levels

Research

Needs Assessment

1. PM Emission

Factors

2. Odors and

Odorants

3. Dispersion

4. Indoor Air Quality, CAFO

Buildings

5. Health

Effects

Technology

Transfer Program Needs

1. Producers and Private

Industry

2. General Public and Affected

Neighbors

3. Public

Programs

4. Technical/Engineering

Assistance

Discussion

of Recommended Program Needs

1. Prioritized

Topics

2. Partnerships

3. Budgetary Requirements &

Recommendations

4. Implementation - Initiatives,

Agency Actions, etc

SUMMARY

REFERENCES

TABLES

APPENDICES

AIR QUALITY RESEARCH AND TECHNOLOGY TRANSFER WHITE PAPER AND RECOMMENDATIONS FOR CONCENTRATED ANIMAL FEEDING OPERATIONS

Report Prepared

by:

Confined Livestock Air

Quality Subcommittee

USDA Agricultural Air

Quality Task Force (AAQTF)

EXECUTIVE SUMMARY

U.S. farmers are leaders in producing the safest and most economical food supply in the world. Each year, U.S. consumers spend less than 11% of their income on food. Concentrated animal feeding operations (CAFOs) have largely contributed to the ability of U.S. producers to meet growing demands for the production of meat, milk, poultry and eggs. To maintain a safe and economical food supply, producers must have sufficient lead-time, cost-effective technologies, and resources to adjust to changing public agendas that include air quality protection. To continue this predominance in agricultural production, the USDA Agricultural Air Quality Task Force (AAQTF) established by Congress in the 1996 Farm Bill, recommends an additional $65 million be annually appropriated for agricultural air quality issues. Of this amount, $12.8 million should be specifically targeted for CAFO research needs.

The following information summarizes the findings of the AAQTF in regard to air quality issues associated with CAFOs. A full discussion of the issues can be found in the “Air Quality Research & Technology Transfer White Paper and Recommendations for Concentrated Animal Feeding Operations”.

CAFO

Air Quality Parameters

- CAFOs can affect air

quality through emissions of odor, odorous gases (odorants), particulates

(including biological particulate matter), volatile organic compounds and/or

some of the so-called greenhouse gases.

- Odor from CAFO sources, as

experienced by humans, is the composite of as many as 170 or more specific

gases, present in trace concentrations either above or below their olfactory

thresholds.

- The primary odorous gases

of concern include ammonia and hydrogen sulfide. However, the importance of ammonia and

hydrogen sulfide to downwind composite odor as perceived by neighbors is

questionable.

- Field and laboratory

research has largely focused on measuring concentrations of odor. Data on emission rates, flux rates and

emission factors are needed to develop science-based policies for the

reduction of CAFO odor and odorants.

- Future research should be

directed toward odorous gases that more closely correlate with odor as

perceived by humans.

- Carbon dioxide, methane

and non-methane reactive organic gases are natural products of manure

decomposition. Strategies to

reduce emissions of odor and odorants are likely to reduce emissions of these

co-product gases.

Emission

Factors

- Improved processes for

updating emission factors for an array of CAFO-related air contaminants, such

as PM10, PM2.5, volatile organic compounds and ammonia

should be initiated.

Human Response and Health Effects

- Concerns with health

effects of odor, odorants, biological and other particulate matter from CAFOs include livestock,

employees and neighbors. Recent

evidence suggests greater secondary health effects on frequently exposed

neighbors than previously documented.

Current Federal and State

Policies

- Water quality concerns

were first addressed in the Federal Water Pollution Control Act of 1972, which

listed CAFOs as point sources. A

patchwork of tailored policies and regulations has attempted to address voids

of groundwater protection and nutrient management, and only in a few cases

have air quality concerns been addressed.

Integrated

Programs

- Integrated programs to

address air quality from CAFOs have not been funded or developed. A collaboration of agencies is needed

to work with issues associated with CAFOs and air quality, just as similar

collaborative activities have succeeded in regard to water

quality.

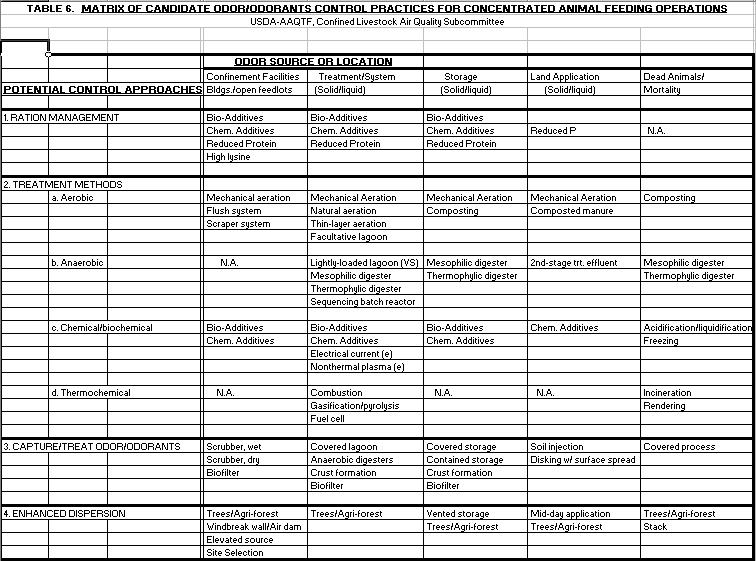

Odor Control

Technologies

- There are four basic

approaches to control odor and odorants: ration/diet manipulation, manure

treatment, capture and treatment of emitted gases and enhanced

dispersion. Each approach has

multiple technologies that need to be tailored on a site-specific

basis.

Dust Control Technologies

- Technologies for

particulate (dust) control from open-lot feeding systems, where needed,

include frequent manure removal, stocking density adjustment to take advantage

of excreted manure moisture and water sprinkling.

Research Funding

- A program of accelerated

research, education, technical training, technology transfer and financial

assistance to address CAFO air quality problems is strongly recommended.

Of the USDA-ARS FY96-99 animal waste research budget of $5.65 million per year and $6.9 million in the CSREES FY97 budget, the amounts devoted to air quality were so small as not to be separately reported.

USDA and EPA funding levels

have not been adequate to address or solve air quality problems associated with

CAFOs. The

USDA AAQTF recommends at least $12.8 million per year for coordinated,

integrated programs for animal agriculture, as part of the additional $65

million in total funding requested for agricultural air quality.

Research

and Technology Transfer Needs

Numerous research and/or

technology transfer needs and opportunities were mentioned in the text of this

report. In brief, these include:

·

Develop accurate and broadly

applicable emission rates, flux rates and emission factors for particulate

matter, odor and specific odorants applicable to CAFOs;

·

Define emission rates as a

function of diurnal, seasonal, and climatic variations, as well as design and

management practices;

·

Develop effective, practical

and economically feasible odor control technologies for confined animals,

treatment, and land application systems;

·

Determine relationships

among odor, odorants, particulates and airborne microbial

species;

·

Identify kinetic release

mechanisms for odorants and odor from principal manure sources and target the

development of control technologies accordingly;

·

Develop practical ways,

capable of widespread adoption, of reducing ammonia from CAFOs;

·

Transfer economically viable

technologies for odor control to all producers regardless if they are a

CAFO or animal feeding operation (AFO);

·

Develop innovative air

treatment processes for confinement building exhausts or covered lagoon

surfaces;

·

Develop odor reduction

treatments for use prior to land application;

·

Develop accurate

standardized measurement technologies for odor, odorants of principal concern,

and fine particulate, and ensure these systems become widely available for

research and demonstration; this should include electronic measurement devices

that are well-correlated with the human odor experience;

·

Develop accurate dispersion

models for odor, odorants, and PM appropriate to specific types of CAFOs,

addressing the inherent problems of Gaussian models;

·

Characterize air quality as

a function of distance from CAFOs;

·

Implement cooperative

industry/agency/university programs for scientific evaluation of new products

for producers’ consideration and adoption;

·

Assess the importance of

indoor air quality at CAFOs and devise ways to reduce exposure

levels;

·

Devise suitable

acceptability criteria for community-level exposure to odor and specific

associated gases;

·

Assess potential

relationships between emission constituents, concentrations, and potential

health indicators, and devise appropriate mitigation strategies

accordingly;

·

Establish partnerships with

health research organizations to identify potential health concerns associated

with CAFOs.

AIR QUALITY RESEARCH AND TECHNOLOGY TRANSFER WHITE PAPER AND RECOMMENDATIONS FOR CONCENTRATED ANIMAL FEEDING OPERATIONS

Report Prepared

by:

Confined Livestock Air

Quality Subcommittee

USDA Agricultural Air

Quality Task Force (AAQTF)

Introduction

Animal agriculture in the

U.S. is important to the nation’s economic well being, producing almost $100

billion per year in farm revenue contributing to the vitality of rural

communities and insuring the sustainability of America’s food supply (GAO,

1999). The U.S. has developed a

very efficient, sophisticated system for production of meat, milk, poultry, and

egg products involving concentrated animal feeding operations (CAFOs). For instance, the United States has 99.0

± 0.9 million cattle and

calves (average ± standard deviation for

1998-2000), and in 1999, a monthly average of 10.32 ± 0.75 million head were in

beef cattle feedlots being finished for slaughter (TCFA, 2000). These finishing cattle generally range

in liveweight from 272 kg (600 lbs) to 544 kg (1,200 lbs) per head, with an

average liveweight of approximately 408 kg/hd (900 lbs/hd). During a normal 150 day finishing

period, each animal excretes about 900 kg (2,000 lbs) of collectible manure, or

about 1,800 kg/hd (4,000 lbs/hd) of manure per head of feedlot capacity per

year. Cattle feedlots in the U.S.

produce an estimated 18 million metric tons/yr (20 million tons/yr) of

collectable manure containing at least 360,000 metric tons/yr (400,000 tons/yr)

of total nitrogen and 135,000 metric tons/yr (150,000 tons/yr) of total

phosphorus (P).

State and federal

regulations have directly addressed water quality protection from CAFOs since

the early 1970s. Accordingly, in

the last 30 years systems designed for manure and wastewater management have

historically been optimized for water quality protection to comply with EPA

effluent limitations guidelines (ELGs) adopted in 1974 and 1976, and currently

being updated. Most states have

surpassed USEPA in requiring groundwater protection measures, nutrient balances

for land application of manure and wastewater. Air quality protection has received

secondary consideration. Changing

regulatory priorities now have begun to include phosphorus and pathogens in

water quality goals and particulate matter, odor, and/or specific odorants in

air quality as goals. For example,

ammonia volatilization was considered a desirable means to balance N for land

application, and only recently has ammonia loss been viewed as a potential

problem in terms of air quality considerations.

Water and air quality issues

are interrelated. There has been a

major lack of adequate research to deal with both water and air quality issues

in a holistic systems approach while maintaining high standards of confined

livestock productivity, animal health, and production cost efficiency. For example, EPA’s anticipated update of

Effluent Limitation Guidelines will likely embrace phosphorus (P) limits in land

application criteria, and lead toward reduced manure and wastewater application

rates in some watersheds. In turn,

this may increase producers’ incentives to reduce N loss and retain N to more

nearly balance nitrogen application rates.

Increased funding is needed for research and development that will

properly quantify particulate matter (PM) and gaseous emission rates as a

function of system design and operational parameters. Public interest in these issues will

need to be tempered by realizations of needed

lead time, resources, and

appropriate technologies for producers to meet a changing public agenda and

avoid major dislocations in animal agriculture, which is an area of very

significant U.S. leadership in the world.

AIR QUALITY PARAMETERS AND

CONCERNS

Concentrated animal feeding

operations (CAFOs), including swine and poultry operations, dairies and cattle

feedlots and the associated animal waste management systems may produce

emissions of odor, odorants, odorous gases, such as ammonia, H2S,

VOCs, “greenhouse” gases (CO2 and CH4), and PM. Regardless of type of contaminant, the

emissions load on the atmosphere in terms of mass per unit time is the product

of contaminant concentration and the air flow rate (e.g., load = concentration x

ventilation rate).

1. Odor and Odorants

Principal sources of odor

emissions may include:

- Production Facilities -- open lot and confinement buildings;

- Manure/wastewater storage and/or treatment systems-- ponds, pits, lagoons, stockpiles, composting operations;

- Land application systems for solid or

liquid manure, treated effluent, or open lot runoff; and

- Animal

mortalities/carcasses.

Odor may become an annoyance

to, and affect the well being of, nearby residents. Odorous gases (odorants) arise from feed

materials, fresh manure, and stored, decomposing or treated manure, and

wastewater. Eaton (1996) listed 170

different compounds present in swine manure odor. Odorous gases emitted from animal waste

include ammonia and amines (Hutchinson et al., 1982; Peters and Blackwood,

1977), sulfides, volatile fatty acids, alcohols, aldehydes, mercaptans, esters,

and carbonyls (National Research Council, 1979; Miner, 1975b; Barth et al.,

1984; ASAE, 1999a). Peters and

Blackwood (1977) listed 31 odorants identified at cattle feedlots, together with

their threshold limit value (TLV) in ppm and odor threshold (ppm), where

known. An olfactory threshold value

detected by human panelists is the concentration where half the panelists detect

and half do not detect an odor.

Consequently, the threshold value may span a range as great as 5 or 6

orders of magnitude for a single compound and range from as low as 7.5 x

10-8 ppm for skatole to as high as 12,000 ppm for formaldehyde

(Eaton, 1996). For instance,

ammonia has reported odor threshold values spanning three orders of magnitudes

ranging from 0.0317 ppm to 37.8 ppm (Eaton, 1996). Concentrations of odorants at downwind

locations are very low; however, some may exceed olfactory threshold values and

create nuisance conditions (Sweeten, 2000b). Odorous compounds generally have not

been considered toxic at concentrations found downwind of livestock feeding

facilities. Mackie et al. (1998)

and Tamminga (1992) cited lowest toxic values (LTV) of frequently cited odorous

gases from confinement buildings.

These LTV values were from 5 to 20,000 times higher than cited odor

threshold values for these compounds.

However, recent evidence suggests potential for adverse health effect in

some instances (Wing and Wolf, 1999).

Odor characteristics that

contribute to nuisance conditions are as follows: (a) the intensity, concentration or

strength of the odor; (b) the odor frequency or number of times detected during

a time period; (c) the duration of the period in which the odor remains

detectable; (d) the perceived offensiveness and character or quality of the odor

(Jones, 1992). These factors

interrelate in causing nuisance conditions. Odor frequency and duration are partly

dictated by climatic conditions, including wind-direction frequency, atmospheric

stability, and moisture conditions.

A weak link in developing

odor abatement technologies has been an inability to precisely quantify odor

strength with sufficient reproducibility and accuracy (Clanton et al.,

1999b). Odor measurement methods

have been applied to animal waste management systems (Bulley and Phillips, 1980;

Barth, et al., 1984; Watts, 1991; Sweeten, 1995; McFarland and Sweeten,

1995). General approaches to

estimate the strength or intensity of livestock manure odors

include:

a. Sensory methods that involve

collecting and presenting odor samples to human panelists (diluted or undiluted)

under controlled conditions, e.g., Scentometer, dynamic olfactometers,

suprathreshold referencing methods, absorption media, etc.

b. Measurement of concentrations of

specific odorous gases (directly or indirectly).

c. Electronic “nose” devices that

register presence, concentration or activity of selected odorous

gases.

Olfactometry is the most

widely used method to evaluate odor concentration. Perhaps the simplest method of field

sensory odor concentration measurement is the Barnebey-Sutcliffe Scentometer

(Barnebey-Cheney, 1987). This

simple, portable field instrument involves direct sampling of the ambient air,

and it has been used as the basis for setting property line odor concentration

standards by several states (e.g., Colorado, Montana, North Dakota) and

cities. The Scentometer has also

been used for field odor measurement at numerous livestock and poultry

operations in the U.S. (Sweeten et al., 1977; Sweeten et al., 1983; Miner and

Stroh, 1976; Sweeten et al., 1991) and in data collection contributing to

nuisance litigation (Sweeten and Miner, 1993). The use of suprathreshold referencing

(ASTM, 1975) for measuring intensity of livestock waste odor was described by

Sweeten et al. (1983 and 1991). The

deployment and improvement of dynamic triangle forced-choice olfactometers

(DTFCO) (ASTM 1991; Dravnieks and Prokop, 1975) for livestock odor research is

occurring rapidly (Watts, 1991; Jones, 1992; Nicolai et al., 1997; Li et al.,

1997) and appears to be the instrumentation of choice for sensory odor

measurement for current research.

For instance, Lim et al. (1999) reported odor concentrations, measured by

8 panelists with a dynamic triangle forced-choice olfactometer, for swine

nursery buildings with underfloor liquid manure storage pits, as 190 odor units

(OU)/m3 in the exhaust air and 18 OU/m3 outside the

building. The data were used to

calculate an odor emission rate per head (51 OU/hd/sec) or per unit area (2.1

OU/m2/sec) using airflow rate data. Regression relationships were found

between odor concentration, odor intensity, and odor offensiveness. Similar data using a DTFCO system was

reported by Heber et al. (1998) for four 1,000 head finishing buildings, which

produced an average odor concentration of 294 ± 65 OU (range of 12-1,586

OU), and an emission rate of 96 ± 30 OU/hd/sec, or 5.0

OU/m2/sec.

Pain et al. (1988) used a

small wind tunnel (2 m x 0.5 m x 0.45 m) to collect samples of odorous air and

to measure ammonia emissions following the surface spreading of liquid dairy

cattle manure (1 to 2 day storage time), before and after mechanical separation

with a roller press, onto grassland in the United Kingdom. Odor samples were collected beneath the

flexible plastic sheet canopy into 50 L Tedlar bags inflated within 4 to 5

minutes time. Odor concentration

was measured by 4 to 8 panelists using dynamic olfactometry with 4 to 6

dilutions of each sample presented for determination of the odor threshold

(ED50) value. The odor

emission rate was calculated as the product of odor units (OU) and the

volumetric airflow rate (odor units/m2/hr). The odor emission rates measured by Pain

et al. (1988) for liquid dairy manure spread on pastures were reported by Smith

and Watts (1994) at 22 OUm/s and 11 OUm/s at time intervals of 3 and 48 hours,

respectively, after spreading. In

essence, the odor emission rate was reduced by 50% two days after spreading

liquid manure. Similar values were

obtained for swine manure slurry.

Total odor emissions were similar for whole dairy cattle manure slurry

and separated slurry (Pain et al., 1988).

Despite standardization and

control procedures to reduce bias, elements of subjectivity and sources of

imprecision remain in odor measurement with sensory panels. Combined with the high cost per sample

of large odor panels, this creates the need for reproducible, inexpensive

instruments that mimic the human olfactory response (Lacey,

1998).

Clanton et al. (1999b)

evaluated several possible sources of variation in determining dilution to

threshold odor units using a dynamic triangle forced choice olfactometer. For the same samples, two different

8-person odor panels consistently produced 22 to 50% differences odor

concentration (measured in odor units), depending on odor strength. Two different olfactometer airflow rates

resulted in 9 to 28% differences in odor units. There were large differences in

individual panelist sensitivity to odor detection and likewise variations by

individual panelists across different testing days and within a testing

session. A learning curve for

individual odor panelists was demonstrated. To improve the probability of detecting

significant reductions in odor resulting from a particular treatment, Clanton et

al. (1999b) recommended that several identical pairs of air samples will be

needed, together with a sufficient number of panelists to achieve statistically

significant differences with current olfactometry

technologies.

Considerable effort has been

devoted to identification and measurement of specific gases within the

atmosphere of livestock and poultry confinement buildings (Burnett, 1969; Elliot

et al., 1978; Hammond and Smith, 1981).

A large number of odorous compounds are present in very low

concentrations. Miner (1974)

reported that the measured concentration of each gaseous compound identified in

animal waste odor was below the reported minimum olfactory threshold. Zahn et al. (1997) reported that

volatile organic acids with carbon numbers from 2 to 9 demonstrated the greatest

potential for accounting for manure odor.

Instruments available to

identify and measure the concentrations of specific odorous gases (odorants)

emitted from animal manures include gas chromatography and mass spectrometry

(GC/MS) (White et al., 1971; Hammond et al., 1974). These methods are very sensitive in

detecting compounds in very low concentrations. Peters and Blackwood (1977) reported

difficulty in positively identifying compounds present in feedlot air samples

using GC-FID (gas chromatography-flame ionization detector) technology. Low peak values precluded the use of

GC/MS for amines. As a result of

the low concentrations of many odorants in and around CAFOs, the compounds may

need to be concentrated further prior to analysis by use of methods such as

solvent desorption, thermal adsorption (Wright, 1994: Zahn et al., 1997) or

solid-phase microextraction (SPME) (Zhang et al., 1994).

An electronic nose is an

array of gas sensors that are combined with pattern recognition software to

mimic human olfactory response (Lacey, 1998). Current commercial applications are

focused on high-valued food products.

Lacey (1998) and Mackay-Sim (1992) listed electronic approaches to

volatile gas (odor) detection: metal-oxide semi-conductors; field-effect

transistors; optical fibers; semi-conducting polymers; and piezo-electronic

quartz crystal devices. These

approaches raise the possibility of remote odor monitoring/surveillance networks

for individual compounds or odorant mixtures. The piezo-electric crystals are

sensitive to changes in surface mass caused by interaction with gaseous

molecules. As mass is added to the

surface, the resonant frequency decreases.

The sensor surface can be designed to respond to single chemicals or

groups of chemicals. Berckmans et

al. (1992) in Belgium developed a thick film semiconducting metal oxide sensor

for monitoring ammonia concentrations within, and emissions from, livestock

confinement buildings. Some sensors

may be affected by water vapor, methane, and temperature (Lacey,

1998).

Collection and storage of

odorous air samples for presentation to panelists or instrumental analysis is an

important consideration (Sweeten, 1995).

Tedlar bags (10-50 L) that are inflated in the field using portable wind

tunnel or negatively-pressurized canisters have become the most commonly used

method.

Schmidt et al. (1999)

described wind tunnel design parameters for odor sampling and concluded that

odor and hydrogen sulfide concentrations and corresponding emission rate

increase with bulk wind speed of the tunnel according to a power function

relationship. Results of Schmidt et

al. (1999) corroborated earlier work by Smith and Watts (1994b) on open

unsurfaced cattle feedlots.

2. Major Gases of Concern – Ammonia

and Hydrogen Sulfide

Ammonia is one of the fixed

gases of both aerobic and anaerobic decomposition of organic wastes. Much of the nitrogen excreted by cattle

is in the form of urea, which rapidly hydrolyzes to NH3. Additional NH3 as well as

amine are produced during microbial breakdown of fecal material in confinement

buildings, on feedlot surfaces, in stockpiles, and in lagoons or runoff

retention ponds. Ammonia evolution

rates are a function of time, temperature, pH of the manure surface, and level

of biological activity. Ammonia

(NH3) volatilization is probably the most important pathway for

on-site loss of nitrogen in animal manure to air and water resources. There are four main sources of ammonia

emissions on a commercial swine facility: confinement buildings, manure and

storage treatment lagoons, land application of lagoon effluent to cropland, and

potential NH3 re-emission from the soil (Aneja et al., 2000a). In the atmosphere, ammonia can react

with acidic species to form ammonium sulfate, ammonium nitrate, ammonium

chloride, or particulate (Aneja et al., 2000a). Battye et al. (1994) reported that

ammonia in the atmosphere can have a significant effect on oxidation and

deposition rates of acidic compounds.

Ammonia concentrations can

be measured by packed bed chemical-specific syringe tubes that are primarily

used in occupational safety and health applications (Sweeten et al., 1991). A second approach is GC/MS as mentioned

previously in which odorant samples are presented to the GC/MS either by vapor

syringe or by solid-phase microextraction.

The third approach is an ammonia (and amine) absorption trap in which a

known volume of air is passed through a weak acid media: sulfuric acid solution

(Luebs et al., 1974; Hutchinson et al., 1982; Cole and Parker, 1999); boric acid

solution (Moore et al., 1995; O’Halloran, 1993); sulfuric acid-impregnated

fiberglass (Peters and Blackwood, 1977).

The ammonia-absorption technique allows for comparisons of ammonia

concentrations and emission rates between various times and locations (White et

al., 1974). A fourth approach

(Oosthoek and Kroodsma 1990; and Phillips et al., 1995), involves

chemoluminescence, in which ammonia and NO2 are converted to NO at

750°C. In a split airstream at 350°C, the NO2 is

converted to NO. Ammonia

concentration is calculated as the difference in NO concentration between the

350° and 750°C airstream. Prior U.S.

research has indicated that ammonia is emitted from surfaces of open, unpaved

cattle feedlots and dairy corrals at concentrations of 360-980 mg/m3 as compared

to background levels of 1-4 mg/m3 (Sweeten et

al., 1999). Ammonia volatilization

losses are reportedly 50% or more of total N excreted from open lot surfaces and

23-70% following field spreading of manure.

Luebs et al. (1974) measured

ammonia concentrations at 1.2 m height upwind and downwind of open-lot dairy

operations near Chino, California, in which 145,000 dairy cows were concentrated

in several farms within a 60 square mile area near Los Angeles. Concentrations of ammonia (distillable

nitrogen) were below the odor threshold concentrations reported for

ammonia. An ammonia concentration

of 540 Fg/m3 was measured

at the downwind corral fence of a 600-cow dairy. This concentration was reduced to 18

Fg/m3 at a

downwind distance of 0.5 miles (0.8 km).

By comparison, ammonia concentrations were 92 ± 89 Fg/m3 at Chino

airport near the center of the dairy area and 4 ± 2 Fg/m3 at a

non-agricultural reference site. Diurnal fluctuations were observed in ammonia

concentration at the Chino airport with highest concentrations between 1800 and

2200 hours (184 Fg/m3) and 0600 to

1000 hours (128 Fg/m3). Much lower ammonia concentrations

occurred in afternoons 1400 to 1800 hours (6 Fg/m3). Fenceline observations at an individual

dairy did not coincide with the diurnal pattern at the center of the dairy

area.

Ammonia volatilized from

liquid dairy manure slurry spread on pastures was measured (Pain et al., 1988)

by drawing air samples from the tunnel inflow and outflow sections through

absorption flasks containing orthophosphoric acid (0.005 M). Ammonia losses following application

were 23 to 70 percent within 10 to 14 days after application, although 80

percent of these losses occurred within 2 days of application. There was a strong correlation

(r2 = 0.94) between odor emissions and ammonia emissions following

application of dairy cattle slurry to the grassland pasture. A similar relationship was obtained for

swine manure slurry. A greater

proportion of ammonia was lost from dairy cattle slurry than from swine

slurry.

Montes and Chastain (2000)

evaluated ammonia losses from sprinkler irrigation of swine lagoon effluent at

two tree plantations (2 and 8 years old) in South Carolina. As compared to prior research of others

(1980-1997) which reported 10-60% ammonia-nitrogen loss through sprinkler

irrigation, they observed erratic losses ranging from (-) 40% to (+) 38%, with a

mean value of 2% ± 16%.

Keck (1997) determined the

influences of manure removal frequency, climatic conditions, and exposed surface

area on ammonia emissions from cattle exercise yards and from wind tunnel

simulations of 7 m2 manured surfaces where airflow volume could be

determined. Ammonia concentration was determined using HCl absorption. Urine caused more than 8 times greater

ammonia emission per unit area than feces (205 mg/m2h vs. 25

mg/m2/h). Daily removal of manure (feces and urine) produced a small

decrease in ammonia emission compared to removal at three-day intervals. Ammonia

emissions were greater in warm season than in cold weather. Reducing the surface

area of manure decreased the ammonia emission.

Schmidt et al. (1997)

conducted field measurements at 5 dairies in Southern California during winter

and summer seasons to determine surface emission rates of ammonia and other

compounds implicated in contributing to PM 10 emissions. Sampling was conducted using a surface

isolation flux chamber (EPA, 1986). Of the compounds studied, ammonia had the

highest flux rate. Manure

stockpiles that were disturbed produced the highest ammonia flux rate. Amine

compounds were not detected above the detection threshold. The average ammonia

emissions for 4 dairies was 11.2 ± 4.3 kg/cow/year projected

from the late summer/early fall testing period, and was 4.8 ± 1.1 kg/cow/yr projected

from the winter testing period.

Oosthoek and Kroodsma (1990)

reported monthly ammonia concentrations of 3.0-4.8 mg/m3 from a

40-cow dairy free-stall housing unit.

Monthly ammonia emission rates ranged from 39 to 60 kg/month, or 1 to 1.5

kg/head/month, where cattle were housed at night. A scraped concrete floor had three times

the ammonia emission rate of a flushed concrete floor (600 mg/m2/hr

vs. 200 mg/m2/hr).

Peters and Blackwood (1977)

measured both ammonia and hydrogen sulfide concentrations at two cattle

feedyards on the Texas High Plains.

These one-time measurements were:

a. Ammonia -- 104-120 mg/m3

b. Total Sulfide -- 5-27.5

mg/m3

There was no correlation

between the NH3 and H2S

concentrations.

Battye et al. (1994)

examined the European literature to arrive at what they termed “rough estimates”

of ammonia emission factors for agricultural and nonagricultural sources in the

U.S. The NH3 emission

factors recommended for use in future U.S. emissions inventories were based

primarily on European factors for animal agriculture and fertilizer

application. The relative

contribution of animal agriculture to the total U.S. ammonia emission inventory

was extrapolated to be as follows: all cattle and calves (43.4%); swine (10.7%);

poultry (26.72%); sheep and lambs (0.7%).

All other sources constituted only 18.5% of total estimated ammonia

emissions but several sources including undisturbed soils were not

evaluated. The “all cattle and

calves” inventory included both unconfined (range and pasture) beef and dairy

cattle as well as beef feedlots and dairies, and similarly for the sheep and

lambs category. The primary source

of data for the Battye et al. (1994) assessment was Asman (1992), who summarized

literature in the Netherlands through 1990. Battye et al. (1994) recommended several

research areas, including U.S. animal agriculture, to enhance the quality of

ammonia emission factors available.

Factors influencing ammonia

emissions from livestock operations include (Battye et al., 1994): type and size

of animal; ration N and amino acids content; N digestibility and conversion;

confinement housing system; and manure handling system. Following spreading, ammonia emissions

are influenced by: climatic conditions, soil properties, manure properties,

application rate, application method, and timing of soil

incorporation.

Buijsman et al. (1987)

likewise produced ammonia emission factors from data in the United Kingdom. The ammonia emission estimates of Asman

(1992), Buijsman (1987), and NAPAP represented both confined and unconfined

cattle and sheep, with values for the pastured animals reportedly higher than

confined animal. Likewise, larger

animals within species reportedly produced higher ammonia emission factors, and

vice versa. However, the data sets

failed to distinguish in similar terms among types of production systems,

housing, or sizes of animals used for the data series, nor between monitoring

methods. Table 1 shows a comparison

of NH3 emission factors for the three European studies and a derived

composite value of Battye et al. (1994) for use by EPA, in which they took into

account types, size, ranges and numbers of farm animals in the U.S. The National Acid Precipitation

Assessment Program (NAPAP) for the U.S. (Warn et al., 1990) reported

NH3 emission factors that Battye et al. (1994) described as “quality

rating E (lowest possible).”

Preliminary estimates of

ammonia emissions from typical open-lot dairies and beef cattle feedlots in

California were developed by the California Air Resources Board (CARB, 1999),

which commented that because of “uncertainties in the number of animals and the

ammonia emissions per animal, it is not possible to produce precise measurements

of regional livestock emissions as can be done for factories or cars”. Their estimates for livestock are based

on averages in developing an ammonia emissions summary for 15 air quality

basins. Difficulties in arriving at

these estimates included partitioning cattle numbers, liveweights, and time

segments into different phases of each type of operation using standard

livestock statistics developed for other purposes. Moreover, CARB (1999) stated that

researchers’ attempts to quantify ammonia emissions from cattle are “an

extremely difficult process; in that emissions vary by type of ration, climate

conditions (temperature, humidity, etc.), type of animal housing or stabling,

where and how measurements were taken, and diverse activities that may

contribute ammonia (e.g., grazing, confinement, manure

handling/storage/spreading, etc.).”

Because of these

difficulties, CARB (1999) estimated emission factors for cattle feedlots based

on the Battye et al. (1994) report, which itself was based on European data

(Asman, 1992) as noted previously.

Accordingly, the weighted-average composite beef cattle emission factor

for all beef cattle and calves in California was taken as 18 lbs

NH3/hd/year. Similarly,

the derived composite estimate for dairy cattle was 30 lbs

NH3/hd/year, as compared to cited emission factors of 17-87 lbs/hd/yr

for dairy cattle.

Data on ammonia

concentrations in cattle feedyards and emission flux rates (mass per unit area)

are sparse, and area from feedlot and holding pond surfaces is sparse. Ammonia-nitrogen (NH3-N)

concentrations measured on 13 days from a 120,000-head feedlot near Greeley,

Colorado, Hutchinson et al. (1982), were compared with measured background

concentrations of 1-4 Fg

NH3-N/m3.

Average concentrations above the feedlot surface were 520 ± 309 Fg/m3. Concentrations on the 10 “dry days”

averaged 361 ± 46 Fg/m3, and peak

concentrations occurred either when the feedlot was drying out (2 days) after

rainfall (1,090 mg/m3) or during

an inversion (1 day), when the concentration was 970 Fg/m3. Conversion of concentration data to flux

densities requires site specific concurrent data on wind speed, temperature,

solar radiation, and boundary layer thickness. Hutchinson et al. (1982) estimated

vertical flux densities of 0.64-2.37 kg N/ha/hr, with an average value of 1.4 kg

N/ha/hr. The highest ammonia

concentrations and flux densities were measured when the feedyard surface was

drying out after rainfall.

Ashbaugh et al. (1998)

conducted several field studies in the San Joaquin Valley, California, to

determine upwind and downwind ammonia concentrations. Ammonia concentrations were highly

variable from different parts of the dairy. Secondary ammonium nitrate particles

form in the atmosphere from ammonia gas and nitric acid. Dairy facilities used were a 2,050 cow

free stall (milking herd size) with 2,350 non-producing heifers on property in

open corrals. The flushed manure

from the free stall barn and milking parlor entered a two-stage solids

separation system (gravity settling basin and mechanical separator) followed by

a primary (single-stage) anaerobic lagoon.

Solid manure was collected from drylots by conventional scraping. Ammonia was sampled using two

approaches:

·

Active samplers -- two-stage

boric acid traps;

·

Passive samplers -- citric

acid coated filter Teflon protective filter inside a standard Millipore filter

cartridge, further described in Freitas et al. (1997).

Meteorological conditions

were monitored to a 12-meter height to allow calculation of ammonia flux and to

determine data quality. The

vertical flux (mass/unit area/unit time) was used to calculate an emission rate

in mass/unit time. The emission

factor was calculated from the emission rate divided by the number of animals at

the dairy. Diurnal effects were

noted as emission factors ranged from 24 lbs/hd/year at night to 227 lbs/hd/year

in the late morning. These results

(Ashbaugh et al., 1998) appeared to bracket the following prior estimates/

measurements of emissions factors for dairy cattle:

Prior Source

lbs/hd/year

Data Source

· Battye et al, 1994

87.6

Europe

· Gharib & Cass, 1984

48.9

S. California

· James et al., 1997

74 ± 130

San Joaquin Valley

· Schmidt et al., 1997

11-25

S. California

Atwood and Kelley, 1996

Ni et al. (1998) observed

ammonia emissions from a 1,000 head swine finishing building with underfloor

liquid manure storage pit of 11.2 ± 4.6 kg/day, or about 13

g/day/head on feed. These

in-building concentrations were generally lower than reported in the European

literature. The emission rate

varied with pig weight, ventilator rate, and indoor air

temperature.

Stowell et al. (2000)

obtained average ammonia concentrations of 16.1 ± 11.6 ppm in fan exhaust air

from a finishing building for 960 hogs with a solid manure handling system,

although concentrations varied among fans and between sampling events. The average ammonia emission rate for

this unconventional type of swine housing was 27.6 g/min (4.1-59.0 g/min), or 41

g/day/head, which is about three times the value of Ni et al. (1998)

(above). The ammonia concentration

diminished rapidly with downwind distance from exhaust fans, to only 1.8 ppm at

3 m, 0.3 at 15.2 m and 0.1 ppm at 30.5 m (100 ft).

Tanaka (2000) determined

that 80% of the ammonia emissions from a forced-aeration dairy manure/sawdust

composting system occurred within the first 3 days, and 90% of ammonia losses

occurred within the first 2 weeks.

Ammonia loss was accelerated by low C/N ratio, with finished compost

substituting for sawdust. These

results are consistent with Sweeten et al. (1991) who used a negative-pressure

collection system to capture and treat (via biofilter) gases from the first week

of a 4-week composting cycle for fresh caged layer manure plus peanut

hulls.

Aneja et al. (2000a)

measured seasonal fluxes of ammonia nitrogen (NH3-N) from a 6.1 acre

(2.5 ha) x 13 ft (4 m) swine manure treatment lagoon at a 10,000 head (~ 1,000

sow farrow to finish) operation in North Carolina for nearly a year

(1997-98). A floating dynamic-flow

flux chamber was used to capture and sample gaseous emissions. Ammonia fluxes varied seasonally ranging

from an average of 305 (February) to 4,017 (August) FgN/m2/minute

(Table 2).

The ammonia flux increased

exponentially as the lagoon surface water temperature increased from

8°C to 38°C (Aneja et al., 2000a and

b). This is related to diffusion

and mass-transfer principles. There

was no correlation between ammonia fluxes and total Kjeldahl nitrogen

concentrations in the lagoon supernatant.

They used GIS satellite images of North Carolina swine lagoons surface

areas, along with the above season average flux rates to compute an estimated

total ammonia emissions from swine lagoons. The total for the lagoons was estimated

to be 33% of the state’s total swine ammonia emissions of ~68,450 tons

NH3-N per year, with the total developed independently from other

published sources, including Battye et al., 1994.

Brewer and Costello (1999)

reported that ammonia fluxes from broiler litter (initial equal mixture of rice

hulls and pine shavings) increased with number of grow-out cycles in which the

litter was reused. Ammonia fluxes

averaged 149 mg NH3-N/m2/hour (range of 0 - 314) during

the first grow-out cycle and 208 mg NH3-N/m2/hour (range

of 40-271) on reused litter. Flux

values varied by location within the broiler houses, and were greatest adjacent

to watering locations due to greater manure deposition and water spillage. Variations also occurred with respect to

bird age, being least during the first week and highest after 15 days through

the end of the grow-out period.

Ammonia flux from new litter was less than from old (reused) litter only

during the first 3 weeks of the initial grow-out period.

Ammonia from swine

facilities in a six-county region with an average hog population of 1,350

hogs/sq mile (528 hogs/km2) in North Carolina are believed to be

impacting precipitation caught in National Atmospheric Deposition

Program/National Trend Network (NADP/NTN) monitoring sites up to 50 miles (80

km) away (Walker et al., 2000).

Hydrogen sulfide is one of

the main gases produced from anaerobic decomposition of swine manure, and can

cause serious indoor air quality problems in confinement swine buildings with

underfloor manure storage pits (Arogo et al., 1999). H2S can cause adverse health

effects to animals and humans (dizziness, headache, irritation, etc.) at

concentrations as low as 10 ppm, and at high concentrations can cause

death. Hydrogen sulfide is formed

and released at low pH conditions (below 7), and is nonexistent at pH above 9 or

10. Arogo et al. (1999) found that

the mass transfer coefficient of H2S increases with liquid manure

temperature, and that higher emission rates of H2S are likely to

occur when liquid temperature is higher than air

temperature.

The Minnesota Pollution

Control Agency (MPCA) recommended three methods of H2S monitoring

(Sullivan et al., 1999):

a. Total Reduced Sulfur (TRS) --

continuous method that uses a thermal oxidizer to convert reduced sulfur

compounds including H2S to a measurable form with an EPA approved

sulfur dioxide analyzer;

b. Sensitized paper tape monitor --

continuous monitor that detects and quantifies dark stain produced by

H2S;

c. Gold film H2S monitor --

portable, handheld H2S gas analyzer; suitable for grab

samples.

MPCA monitored 137 animal

feeding facilities for hydrogen sulfide emissions in 1998, and found that 24

operations demonstrated a “potential to exceed” the state’s ambient air quality

standard of 30 ppb for a one-half hour averaging period.

The MPCA team’s observations

were not uniformly distributed based on animal species, size or type of

operation, and half were selected based on prior complaints. Highest concentrations came from swine

and poultry facilities total confinement systems, and from earthen storage

basins for liquid manure (not treatment lagoons). There was essentially no correlation

between size of operation (based on number of head) and H2S

concentrations at or near the property line (Sullivan et al.,

1999).

Bicudo et al. (2000)

continuously monitored H2S at and around three swine farms

(1,800-3,000 hd) and one dairy farm (667 hd) in Minnesota for 30 days. The continuous air monitors were located

at varying distances and directions from the confinement buildings or earthen

basins. Agitation and pumping of

the manure storage units occurred for 1 to 10 days in August or September. Air samples collected in 10 L Tedlar

bags for analysis by odor panels or H2S instrumentation. Peak concentrations of H2S

during agitation and pumping of earthen basins for manure storage were

significantly higher than from the basins with deep pits, and frequently

exceeded the 92 ppb recording range of the continuous air monitors for about 4

hours, then decreased rapidly to levels below 30 ppb. Even during agitation and pumping, odor

concentration (OU) and H2S diminished rather rapidly with distance

downwind, to levels of below 20-50 OU and 0-30 ppb, respectively, at distances

of 200-250 m.

Ni et al. (1999a) reported

H2S emission rates from two 1,000 head grow/finishing swine buildings

with underfloor liquid manure storage pits. H2S emission rates

averaged 0.591 kg/day per building (range of 0.32-1.867 kg/day), which equated

to 740 mg H2S/day/m2 building floor area. Average H2S emission per head

of building capacity was 6.3 mg/hd/day.

Emission rates for H2S were directly proportional to room

temperatures and airflow rates but pig size was not a significant

parameter. According to Ni et al.

(2000), prior work has reported 5 to 95 mg H2S/m2/hour

from swine finishing buildings in the Upper Midwest. There is a need to identify other

important odorous compounds and determine how they are generated and how to

control them. Ni et al. (2000)

found that SO2 was produced in simulated liquid manure storage pits

along with H2S, but at about one-tenth the concentration (e.g., 20-25

ppb SO2). Releases of

H2S fluctuated more drastically than for

SO2.

3. Particulate Matter –

PM10 & PM2.5

The cattle feedlot industry

is under increased scrutiny and regulatory involvement at state and national

levels with regard to particulate matter (PM) emissions from fugitive

sources. USEPA (1987) replaced the

total suspended particulate (TSP) standards for all sources in the U.S. with a

PM10 standard based on particulate matter (PM) having mass median

diameter of 10 microns (Fm) (AED). In essence, the revision was based on

the premise that relatively fine, rather than coarse dust, needs to receive

greater focus in protecting human health.

The PM10 primary and secondary 24-hour standards were changed

to 150 Fg/m3 for a

24-hour average with no more than one exceedance per year (USEPA, 1987). Two instruments (manufactured by Wedding

and Associates and by Sierra Andersen) were accepted for PM10

measurement by the USEPA, and other instruments or methods have been developed

as well (Herber and Parnell, 1988).

A procedure developed by

Raina and Parnell (1994) involved use of a Coulter Counter to determine particle

size distribution of particulate collected with a high volume sampler and, based

on these measurements, mathematically deriving the PM10

concentration. Their data with

agricultural processing dusts suggested that the Coulter Counter method may give

a more accurate indication of (a) median aerodynamic particle diameter, and (b)

cumulative PM10 concentration.

With increasing concerns

for human health effects believed caused by fine particulate matter (respirable

dust), the USEPA proposed new National Ambient Air Quality Standards (NAAQS) in

July 1997. The proposal would

provide new primary and secondary standards for PM2.5 (AED). The proposed 24-hour primary and

secondary PM2.5 standard was 65 Fg/m3 calculated as the 3 year average of

the 98th percentile reading at each monitor. The proposed annual standard was 15

Fg/m3 as the 3-year average of annual

arithmetic means. In addition to

the new PM2.5 standard, the 1987 NAAQS for PM10 would be

left in place, except that the PM10 exceedance criterion for 24 hour

samples would be changed to 99th percentile (i.e., 4th

highest concentration) rather than one exceedance per year. It is important to note that the

proposed new NAAQS has not been adopted by USEPA due to a 1999 court

decision. The current NAAQS for

PM10, as well as the other criteria pollutants are provided in Table

3. The PM10 primary

standards are 50 Fg/m3 for the annual arithmetic mean, and

150 mg/m3 as the 24-hour maximum concentration

(Woodford, 2000).

Measurements of total

suspended particulate (TSP) with standard high volume samplers both upwind and

downwind of 25 California feedlots during the summer resulted in an average net

TSP concentration of 654 Fg/m3 with a range

of 54 to 1,268 Fg/m3 (Algeo et

al., 1972). The net TSP was the

difference between the downwind and upwind concentrations and reflected the dust

contribution from the feedlots. The

peak daily total suspended particulate concentrations were usually observed at

or just after sundown for 2 hours (1900 - 2200 hours local time), and ranged

from 1,946 to 35, 536 Fg/m3, averaging

14,200 ± 11,815 Fg/m3 for 10

feedlots (Elam et al., 1971). The

high peak dust concentrations in early evening result from increased cattle

activity as ambient temperatures drop following daytime heating. Dust control practices in place for 2 of

the 10 feedlots reduced concentrations to 1,446 and 3,153 Fg/m3 at the peak

hours. Minimum dust concentrations

observed in early morning (0600 hours) were one or two orders of magnitude below

the maximum and mean TSP concentrations.

At three Texas feedlots,

Sweeten et al. (1988) measured net particulate (TSP) concentrations for 24 hour

sampling periods. Net particulate

concentrations are the downwind concentration adjusted for upwind concentration

to reflect the contribution of the feedlot only. Net concentrations averaged 410

Fg/m3 and ranged

from 68 to 882 Fg/m3. For 4 and 5 hour time intervals within

the 24 hour sampling periods, the extreme range of TSP dust concentrations was

16 to 17,000 Fg/m3.

Concentrations of total

suspended particulate matter (TSP) and PM less than 10 micrometers

(PM10) aerodynamic equivalent diameter (AED) were measured, using

high volume samplers, and Sierra Andersen samplers respectively (Sweeten et al.,

1998). Particle size distributions

of dust captured on sampler filters were measured with a Coulter Counter model

TAII. Mass median diameters for

high volume and PM10 samplers averaged 9.5 ± 1.5 and 6.9 ± 0.8 Fm (AED), respectively. Three cattle feedlots (17,000 to 40,000

head capacity) in the Southern Great Plains were used in the

study.

TSP concentrations measured

at the same downwind locations for 5-hour time intervals ranged from 97 to 1,685

Fg/m3 TSP and

averaged 700 + 484 Fg/m3 TSP (Sweeten et al., 1998). Correspondingly, the PM10

particulate concentrations ranged from 11 to 531 Fg/m3 and averaged

285 + 214 Fg/m3. In all cases, these results represented

the approximate center of the downwind plume at the location of the samplers

(i.e., 15 meters to 61 meters beyond the feedpens). The Andersen PM10 sampler

yielded a much higher PM10/TSP ratio (0.40) than for two Wedding

PM10 monitors (0.19) used simultaneously in several experiments (data

not shown). Particles smaller than

2.5 mm (AED) represented

approximately 5% of TSP.

Guarino et al. (1999) found

that peak levels of dust released in a caged layer poultry building were

generated by rather sudden episodes of increased bird activity triggered by

noise, lighting changes, machinery, human activity, or increased

temperature. Diurnal patterns were

observed (highest during day and least at night). Increased total and respirable dust

levels resulted in increased poultry mortality.

4. Co-Product Gases – CO2,

CH4, and VOC

The major sources of

CO2 in swine buildings are space heating systems, animal respiration,

and massive biodegradation (Lim et al., 1998). Recommended maximum allowable

CO2 levels range from 1,500 ppm to 5,000 ppm for 8-hr human

exposure. Manure degradation can be

a major source of methane (CH4) and nitrogen oxides (NOx),

which contribute to the inventory of greenhouse gases (Mackie et al.,

1998). Emissions of nitrous oxide

(N2O) during the nitrification/dentrification cycle can contribute to

ozone depletion (Schulte, 1997). In

the U.S., methane emissions from animal wastes are 15% of the total (Mackie et

al., 1998; USEPA, 1992). Methane

fermentation occurs in many anaerobic ecosystems, including manure storage and

treatment, where the main electron acceptor, CO2, is produced from

the degraded organic substrates.

Lim et al. (1998) reported

CO2 concentrations in fan exhaust from an 880 hd grow/finish swine

building with total slotted floors and tunnel ventilation with curtain side

walls. Average CO2

concentration inside was 1,060 ppm (539-2,766 ppm range), as compared to 482 ppm

outdoors. Carbon dioxide production

averaged 3.0 kg/pig/day (1.2-9.5 kg/pig/day range).

Safley et al. (1992)

reported that the atmospheric concentration of methane (CH4) is

presently about 1.7 ppm; is increasing at the rate of 1% per year; and has more

than doubled over the last two centuries.

Methane contributes about 20% of the expected global warming effect,

behind carbon dioxide. Animal waste

contributes about 6-10% of the total worldwide anthropogenic methane emissions,

and North America ranks fourth, behind Eastern Europe, Asia/Far East, and

Western Europe, producing about 15% of the 28.3 Teragrams CH4/year

from animal waste. The principal

determinants of methane production from animal manure are: quantity and

characteristics, waste management system utilized, temperature, and

moisture. Methane is produced

during anaerobic decomposition, resulting from high moisture content and the

absence of oxygen. Systems that

bring the manure/wastewater in contact with oxygen (e.g., timely land

application on fields) reduce methane production. Anaerobic lagoons were estimated to

produce about one third of methane production from animal waste in North America

followed by extensive ranges/pastures, liquid manure/slurry storage, open lots,

solid storage, and land application.

Volatile organic compounds

(non-methane reactive organic gases) are recognized as a major precursor to

ozone formation. Currently, no

recognized emission factors for VOC exist for CAFOs from which states can

develop reliable emission inventories and/or cost-effective mitigation measures

where required.

Emission

Factors: A CASE FOR ACCURACY

1. Significance of Emission

Factors

Emission

factors

are estimates of the mass of pollutants per unit of through put or

capacity. For example, the emission

factor for particulate matter (PM) from a coal-fired power plant is usually

expressed in units of pounds per million Btu of thermal input; a cotton gin,

pounds per bale; and a cattle feedyard, pounds per thousand head per day. The

annual total suspended particulate (TSP) emissions from a 1,000 megawatt power

plant (30% efficient) with an emission factor of 0.03 pounds per million Btu is

1,494 tons per year; from a 20 bale-per hour cotton gin processing 20,000 bales

per year with an emission factor of 3.05 pounds TSP per bale is 30.5 tons per

year; and from a 40,000 head cattle feedyard with an emission factor of 280

pounds TSP per thousand head per day is 2,044 tons per year. (These example operations are well above

the average size for each industry.)

Emission factors are often

used in a regulatory context. The

use of emission factors by EPA and state air pollution regulatory agencies

(SAPRAs) can significantly impact agriculture. EPA has published estimated emission

factors for many types of operations in a document referred to as AP-42 (USEPA,

1986 and 1994). However, many of the agricultural emission factors in AP-42 are

proving to be incorrect and in need of updating.

EPA and SAPRAs use emission

factors in air pollution regulatory process in two ways:

a. to determine the emissions inventory for the operation

(tons per year), and

b. to estimate the downwind concentration that might be

expected from the operation.

The annual emissions

inventories are used to determine whether the operation is a “major

source”. For example, any point

source in an attainment area that emits more than 100 tons per year of a

regulated pollutant is classified as a major source and must pay an annual

emission fee to the respective state’s air fund. This fee is approximately $30

per ton of all regulated pollutants emitted.

Emission

rates

are the mass of air contaminant released per unit of time, calculated as (1) con-centrations in air times airflow

rate or (2) emission factor times capacity or through put. The emission rates of the example power

plant, cotton gin and cattle feedyard listed above are 341, 61, and 467 pounds

per hour, respectively based on AP-42 values (USEPA, 1986). Emission rates can be used to estimate

downwind concentrations with a dispersion model.

There is another factor that

impacts the air pollution regulatory process for PM. The National Ambient Air

Quality Standard (NAAQS) for particulate matter is a 24-hour concentration of

150 micrograms per standard cubic meter of PM10. PM10 is

particulate matter less than 10 micrometers aerodynamic equivalent diameter

(AED). In the examples listed

above, it is likely that the emissions from the power plant will consist

primarily of PM10 whereas only a fraction of the PM emitted by the

cotton gin and feedyard are PM10. It is generally accepted based upon

studies by Texas A&M University and USDA that the fraction of PM less than

10 Fm AED is less than 50% and

25% of the total PM emitted for cotton gins and cattle feedyards,

respectively. Hence, the emission

rates of PM10 that would likely be used for dispersion modeling

downwind from a power plant, cotton gin, and cattle feedyard would be 341, 30,

and 117 lbs/hr, respectively. Likewise the annual emission inventories for the

power plant, cotton gin, and cattle feedyard would be 1494, 15, and 511 tons/yr

of PM10. These emission rates would be correct assuming that the

initial AP-42 emission factor for total PM emitted was correct.

However, there are serious

problems associated with either incorrect or non-existent emission factors for

agricultural operations:

a. If the current AP-42 emission

factors are in error, the emissions inventory will be inaccurate. An inaccurate

emissions inventory will likely result in SAPRA or EPA strategies that are

inappropriate, i.e. if the emissions inventory were inordinately high as a

consequence of an excessively high AP-42 emission factor, excessive regulatory

actions will result in a focus on an agricultural pollutant source when in fact

the contribution of these sources may not be significant.

b. If the current AP-42 emission

factors are in error, modeling will result in incorrect estimates of downwind

concentrations, i.e. if the emission factor is too high resulting in modeled

concentrations at the property line exceeding the NAAQS, additional controls

will be required. In one state, modeled concentrations exceeded the NAAQS at the

property line but measured concentrations were less than the NAAQS and the SAPRA

indicated that they preferred the model results.

c. An even more serious problem is

when no AP-42 emission factor exists.

The SAPRA is likely to assume an emission factor for the agricultural

operation that is incorrect or inappropriate. For example, California is in the

process of permitting dairies. In

the absence of an AP-42 emission factor for dairies, the assumption was made by

the SAPRA that dairy operations are similar to cattle feedyards, and

consequently the inaccurate PM10 AP-42 emission factor for cattle

feedyards was used. Three mistakes

were made in this assumption: (1) Dairy operations are significantly different

from cattle feedyards; (2) dairy cattle do not exhibit the same aggressive

behavior patterns as beef cattle on feed, thereby do not create the same level

of dust emissions; and (3) the AP-42 emission factor for feedyards is

excessively high.

2. Emission Factors for Cattle

Feedyards and Dairies

The Department of

Agricultural Engineering at Texas A&M University has been attempting to

correct the AP-42 emission factor for cattle feedyards since 1992. In the latest study funded by the Texas

Natural Resource Conservation Commission (TNRCC), it was determined that the

appropriate PM10 emission factor for cattle feedyards should be 15

pounds per thousand head per day (lbs/1000hd/day). The AP-42 PM10 emission

factor for cattle feedyards is 70 lbs/1000hd/day. The factor developed in the TNRCC study

was approximately 1/5 of the emission factor listed in AP-42.

Dairy operations are

considerably different than cattle feedyards but there exists no AP-42 emission

factors for dairy operations.

Hence, the California Air Resources Board (ARB) has required that the

cattle feedyard emission factors be used.

This reflects a lack of knowledge of mechanisms of dust emissions at

dairies. The generation of

PM10 in an open feedyard or open dairy lot surface is a consequence

of the cattle (cows) walking on the manure pack entraining dust in air. Calves typically will be on the pavement

or on pasture and will not be disturbing the manure pack. Hence, one should not include the calves

in the determination of the annual PM10 emission inventory. The spacing of cows in dairies are

typically 500 to 1200 square feet per head (ft2/hd) in contrast to

cattle in feed yards at 150 ft2/hd. Milk cows are less active than cattle on

feed yards and are on paved alleyways and milking parlors for a portion of time

each day. Manure in open lot

dairies must be removed frequently for milk inspection purposes whereas there is

no manure removal requirement for feedyards. (Removing manure from feedyards is a

management practice used to reduce PM10 emission rates from cattle

feedyards.) Hence, it is logical to

assume that the frequent removing of manure at dairies will further reduce the

PM10 emission rate. It is likely that the emission factor for cows on

dairies will be significantly less than the emission factor for cattle on

feedyards. Sweeten (2000c) has

estimated that the dairy cattle PM10 emission factor would be less

than 20% of the cattle feedyard PM10 emission factor. If the emission factor used for the

TNRCC study (15 lbs/1000hd/day) is correct, a more appropriate PM10

emission factor for dairies would be 4 lbs/1000hd/day.

The use of an appropriate

emission factor for dairies in California is very important for the dairy

industry. If the ARB were to use an inappropriate and unfair PM10

emission factor for dairies in California, other states will likely use similar

numbers. At the same time, it is important that an accurate emission factor be

used so that the impact of the emissions of PM10 from this project on

the state’s non-attainment status can be quantified.

Table 4 shows the emissions

inventory calculations for four dairy projects in California using three

different emission factors. The

total PM10 emissions from the four proposed dairies range from 33 to

558 tons/year. Which annual emissions inventory figure is correct?

3. Errors in the AP-42 Cattle Feedyard

Emission Factor

Parnell et al., (1999) completed a TNRCC emission inventory study in December 1999: The goal was to report “the most accurate” emissions inventory for PM10 from cattle feedyards in Texas. A logical approach would have been to take the emission factor multiply times the number of head of cattle in the feedyards and report the results. For example, the current AP-42 (EPA, 1995) emission factor for cattle feedyards is 280 pounds of total suspended particulate matter (TSP) per 1000 head per day (lbs/1000hd/d). Based upon work published by Sweeten et al. (1988, 1998), EPA has adopted a policy that 25% of the TSP is PM10. Hence the current PM10, AP-42 emission factor is 70 lbs/1000hd/d. The problem with this approach is that if the emission factor is in error, the emissions inventory will be in error. In addition, this error will be magnified with the emissions inventory calculation. An emissions inventory is calculated by multiplying the emission factor by a large number such as 3 million head (the approximate number of cattle on feed in Texas). For our TNRCC report, we reexamined the basis for the AP-42 emission factor for cattle feedyards (see Appendix A).

Emission factors are also

used by modelers to estimate downwind concentrations from sources of pollution.

Inaccurate emission factors can result in inaccurate estimates of downwind

concentrations of PM10. Inaccurate estimates of downwind

concentrations can result in inappropriate, costly, and unfair imposition of

control strategies.

Agricultural engineers at

Texas A&M University have been conducting research with the goal of

correcting the AP-42 emission factor for cattle feedyards for a number of years

(Parnell, S., 1993, 1994, and 1995; Sweeten et al., 1988 & 1998; McGee,

1997). It has not been a simple task. Measurement of downwind concentrations

does not directly yield emission factors. In other words, a measurement of

PM10 does not directly reflect the emission rate or emission factor

of a fugitive source. The emission factor is affected by localized meteorology,

configuration of the yard, and the dispersion model used to back into the

emission rate.

The current AP-42 TSP

emission factor for cattle feedyards of 280 lbs/1000hd/d can be traced back to

Peters and Blackwood (1977) who used the data collected by Algeo et al.

(1972). The purpose of this

analysis is not to be critical of the previous research, but to point out

errors. By understanding what has

been used for a “scientifically based” emission factor, we can better justify

our approach and resulting emission factor. Peters and Blackwood used the net,

downwind, 24-hour concentrations reported by Algeo from sampling at 25

California feedyards. It should be

mentioned that these were the only data on net, downwind, 24-hour TSP

concentrations from feedyards available at the time. California is in a winter-rainfall area,

and feeds less than 5% of the nation’s cattle, in contrast to the

summer-rainfall climate of the Southern Great Plains, where 80% of the nation’s

cattle feeding activity is located.

The intent of the field sampling study by Algeo et al., (1972) was to

evaluate the performance of control strategies in reducing TSP and their

experiments were not designed to obtain data for the development of a cattle

feedyard emission factor.

Accordingly, neither weather data, locations of samplers, nor feedlot

orientation were reported. Several

unwarranted assumptions or miscalculations were used by Peters and Blackwood

(1977) in their source assessment contract report, which lead to an erroneous

EPA emission factor for cattle feedlots, based solely on summer time TSP data at

California feedlots. Some of these

assumptions were as follows:

a. Infinite line source Gaussian

model;

b. Average feedlot size of 8,000 head

assumed vs. 20,000-25,000 head actual average;

c. Average animal spacing of 150

ft2/head, which is higher than average for California

feedlots;

d. Square feedyard shape factor;

and

e. Erroneous coefficient in emission

rate equation.

Further details and analysis

are provided in Appendix A, along with an improved procedure for determining TSP

emission rate from available data and to determine PM10 emission rate

from TSP data.

4. Comparison of Emission Factors

Using a Line Source (TAMU Process) and ISC Dispersion Modeling

McGee (1997) used Industrial

Source Complex version 3 (ISC3) to back-calculate emission factors from cattle

feedyards using the average 24-hour TSP net concentrations reported by Sweeten

et al. (1988) for each of the three feedyards sampled (Table 5). He used meteorological data in his

modeling and assumed the yards were square with 150 ft2/hd. As a check to see if the above procedure

would yield similar emission factors, we calculated the emission factors using

the TAMU procedure (Appendix A), with the results shown in Table

4.

Note that the TSP emission

factors (Table 5) were the same (97 versus 103; 50 versus 48; etc.) regardless

of whether we use ISC3 or the TAMU procedure. It should also be noted that ISC3

utilizes small area sources with a subsequent integration over the area in the

calculation of downwind concentration whereas the TAMU procedure utilizes a very

simple line source algorithm. The

grand mean concentration of 412 Fg/m3 yielded a

TSP emission factor of 20 lbs/1000hd/d (PM10) (uncorrected for

rainfall events). It would seem

that the TAMU procedure could be used to determine emission factors for cattle

feedyards.

5. PM

Concentrations

One of the issues that was

not addressed above is what net, downwind, 24-hour PM10

concentrations would be expected from a dairy compared to a feedyard. If the

dairy cows were as active as cattle on feedyards, the spacing of 1000

ft2/head would reduce the area emission rate by 6.7 (1000

ft2/head/150 ft2/head). Another way of describing this is