Smart

SamplingTM:

Making sensible

remediation decisions Smart SamplingTM is a process that

facilitates cleanup decisions by applying techniques,

methods, and software that have been developed in other

fields. Through the use of Smart SamplingTM,

site owners, regulators, and other stakeholders can

consider the effects of various action levels and risk

tolerances on the ultimate cost of a remediation plan.

Sandia National

Laboratory developed Smart SamplingTM

with support from the U.S.

Department of Energy's Office of Science and

Technology. The Smart SamplingTM

method has been demonstrated on a number of projects

since 1992, and it is ready for large-scale deployment.

During 1996, Smart SamplingTM

was demonstrated at Site 91 at SNL in Albuquerque, New

Mexico, where 13 test detonations between 1979 and the

late 1980s released 100,000 pounds of lead over the site.

Smart SamplingTM was

also demonstrated in 1998 at the Mound Plant in Ohio.

Decisions, decisions!

Smart SamplingTM

supports cleanup decision makers who must agree on the

cleanup goal and the level of risk to accept in deciding

on a remediation plan. For example, during negotiations

over plans at Site 91, Smart SamplingTM

helped decision makers understand the economic

consequences of selecting between two cleanup

goals—residential or industrial land use. The U.S.

Environmental Agency has set lead cleanup for a future

residential land use scenario at removal or treatment to

the 400 parts-per-million (ppm) action level. The

corresponding action level for industrial use is 2,000

ppm.

What are the risks?

The risk of any remediation plan is that it can

under- or overestimate the degree of cleanup required to

satisfy the action level. Proceeding with a plan that

overestimates the amount of soil that must be removed or

treated results in unnecessary added expense. Such a plan

is based on false positives. Remediation plans that

underestimate the amount of soil for removal or treatment

are based on false negatives; they fail to achieve

regulatory compliance, leading to fines, penalties, and

more remedial actions.

Smart SamplingTM is a

tool for illustrating the economic consequence of

accepting various levels of risk. For example, a

remediation plan based on a 5 percent probability that

remaining soil will exceed the action level will be less

expensive than a remediation plan based on a 1 percent

probability of leaving behind soil that exceeds the

action level. Smart SamplingTM

quantifies the tradeoffs between accepting higher levels

of risk and lower remediation costs.

Taking Smart SamplingTM steps

Smart SamplingTM

is a generic process that can be applied at any site

where negotiating parties must decide to what level to

clean a site. Among the steps in the process are

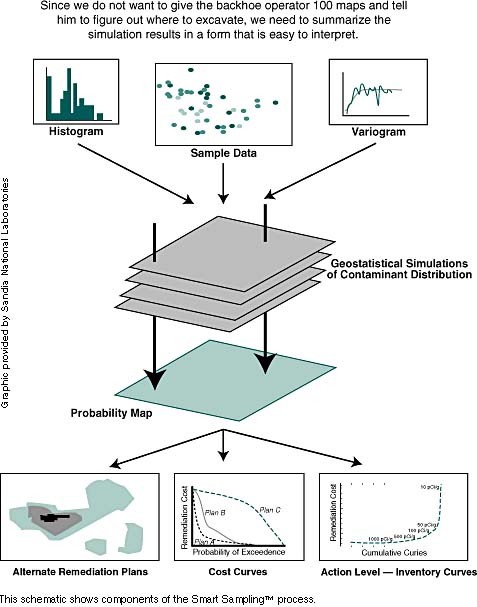

- Histogram—From data

obtained on contaminant concentrations at sampled

locations, Smart SamplingTM

generates a histogram to display the known

distribution of contaminant concentrations.

- Variogram—A variogram is

generated to quantify the spatial correlation

that exists in geostatistics between pairs of

samples. In geostatistics, the differences in

values between pairs of samples will decrease as

their proximity to each other increases. Smart

SamplingTM

applies spatial correlation algorithms to sampled

values to predict values at unsampled locations.

A variogram is a graphical display of this

correlation.

- Geostatistical simulations—Next,

the Smart SamplingTM

process uses the histogram, the sample values and

locations, and the variogram to perform

geostatistical simulations. Many models are

generated to show likely concentrations and

distributions of the contaminant of interest

across a site. Each model accounts for all known

information and is equally plausible in

predicting concentration and distribution at

unsampled locations.

- Probability maps—Smart

SamplingTM

averages all the modeled values and maps them,

showing the likelihood that the true contaminant

value at any unsampled location exceeds the

selected action level. During its use at SNL,

Smart SamplingTM

produced four probability maps to help decision

makers understand how the lower action level (400

ppm as opposed to 2,000 ppm) and higher tolerance

for risk (5 percent as opposed to 1 percent)

affected the amount of soil to be removed and,

therefore, the cost of remediation. Probability

maps provide insight as to the most productive

and cost-effective alternatives for remedial

design, and they quantify the risks associated

with each alternative.

- Excavation maps—Smart

SamplingTM

generates excavation maps from the probability

maps by marking for cleanup those cells with the

selected probability of containing soil that

exceeds the action level (either 400 ppm or 2,000

ppm in the SNL case at Site 91).

- Cost curves—Seeing how

costs were affected by decisions about action

level and probability of exceedence helps

decision makers clarify their options and

understand the economic tradeoffs among various

combinations of action levels, more

characterization sampling, and negotiated levels

of uncertainty. At SNL's Site 91, Smart SamplingTM showed the parties

that if they were willing to accept a remediation

plan based on a 5 percent probability of leaving

soil that exceeded an action level of 2,000 ppm,

then they could save $6.6 million over a plan

with a 5 percent probability of exceeding the

400-ppm action level. Because all parties were

involved in setting cleanup and risk levels, the

resulting remediation plan was defensible.

Taking additional

samples

People responsible for cleanups may decide to take

additional samples to reduce the risk that undetected

contamination will be left in place. Taking additional

samples is economical when the data generated by

additional samples reduce the cost of remediation beyond

the cost of taking the samples. Smart SamplingTM allows for the use of

several algorithms to determine sample locations with the

greatest potential of reducing uncertainty and

contributing to a cost-effective cleanup.

At Site 91, 20 random follow-up samples were taken to

validate the geostatistical model. For each additional

sample location, the sample value was compared with the

distribution of lead concentrations predicted through

geostatistical simulation. The variability between

measured values and predicted values was dependent on

proximity of new sample locations to original sample

locations. Comparing data from the new locations with

values for these locations generated through

geostatistical simulation showed that Smart SamplingTM was effective in preventing

false negatives (where contaminated soil is incorrectly

classified as uncontaminated and left behind at the

site). For example, the accuracy of the remediation

decision based on a 2,000-ppm action level at a 0.05

probability of exceedence was found to be 85 percent (17

correct decisions for the 20 extra sampled locations).

One false negative and two false positives were

identified.

Smart SamplingTM at the Mound Plant

A recent demonstration of Smart SamplingTM at DOE's Mound Plant in

Miamisburg, Ohio provides another illustration of how the

method can help negotiating parties make cost-effective

and defensible remediation decisions. In 1969, a rupture

in an underground pipeline released waste from a

plutonium processing facility at the Mound Plant.

Although a cleanup action was carried out in 1969,

samples taken during the next 24 years showed that a

1-mile section of the abandoned Miami-Erie Barge Canal

was contaminated.

Making decisions about the canal's cleanup lies with

DOE, the Ohio EPA Office of Federal Facilities Oversight,

the U.S. EPA Region V, and local citizens. Recently, DOE

and the regulators authorized a demonstration of Smart

SamplingTM to learn how

the process could help the parties agree on a remediation

plan that removes all soil where the probability of

exceeding 75 picocurries per gram (pCi/g) of plutonium is

greater than or equal to 5 percent. A second goal of

cleanup is to remove all soil where the probability of

exceeding 150 pCi/g is greater than 1 percent. The

parties also want to accomplish cleanup at reasonable

cost.

To restrict the scope of the demonstration, only three

sections of the canal (of 150 sections) were chosen to

exemplify how Smart SamplingTM

supports decision making. One hundred fifty-two samples

were obtained and analyzed on site.

The Smart SamplingTM

process culminated with an excavation plan for removing

about 95 percent of the plutonium at a cost of $67,000.

The site's original excavation plan would remove about 97

percent of the plutonium at a cost of $108,000. Smart

SamplingTM also

generated a cost curve that illustrated the diminishing

returns from additional excavation. Regulators, site

owners, and others saw the cumulative effect on cost of

removing more soil and higher percentages of plutonium.

For more information about Smart SamplingTM, see its page

on Sandia National Laboratories' Web site (http://www.nwer.sandia.gov/sample).

Contacts include Paul Kaplan, Sandia National

Laboratories, (505) 284-4786, pgkapla@nwer.sandia.gov,

and Anthony Armstrong, Oak

Ridge National Laboratory, (423) 576-1555, armstrongaq@ornl.gov.

An Innovative

Technology Summary Report on Smart SamplingTM is scheduled

for release in 1998 by the Office of Science and

Technology.

|