DOE's Office

of Science and Technology

is funding the Accelerated Site Technology Deployment

(ASTD) program, formerly known as the Technology

Deployment Initiative (see back issues of Initiatives).

Projects in the program promise to reduce the cost of

environmental management and accelerate cleanup

throughout the complex.

Linking

two systems to consolidate tank waste

One of the ASTD projects for FY 1998

is the implementation of an integrated cesium removal and

evaporator system to concentrate tank waste at Oak Ridge National Laboratory

(ORNL). During other deployments planned for the Savannah River Site, the

cesium removal and evaporator systems will separately

attack different problems.

By joining the cesium removal unit with the

subatmospheric evaporator, the ASTD project will

efficiently reduce the radioactivity and volume of tank

waste. This project contributes to ORNL's effort to

consolidate its tank waste into a few designated tanks in

preparation for the site choosing private-sector

contractors to treat and dispose of ORNL's tank waste.

Both systems have already been successfully demonstrated

separately. A full-scale demonstration of the cesium

removal technology was funded jointly by DOE's offices of

Science and Technology (OST, EM-50) and Waste

Management (EM-30)

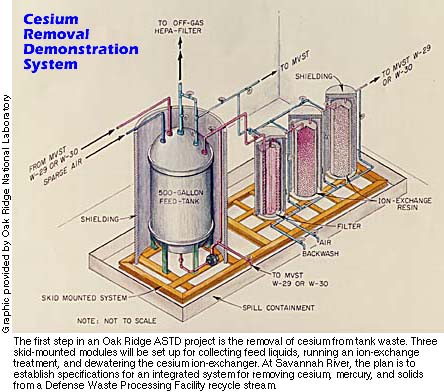

and conducted at ORNL in September 1997. This system is

composed of three compact, skid-mounted modules—one

for collecting feed liquids, one for an ion-exchange

treatment, and one for dewatering the cesium

ion-exchanger. Each module has secondary containment and

modular radiation shielding. A key component of this unit

is the effectiveness of the ion-exchange material,

crystalline silicotitanate (CST), an inorganic

ion-exchange material that was developed in laboratory

tests through the combined efforts of Sandia National

Laboratories, UOP Molecular Sieves, and Texas A&M

University. During its demonstration, the unit removed

1,000 curies of cesium from 30,000 gallons of surrogate

waste using 70 gallons of CST.

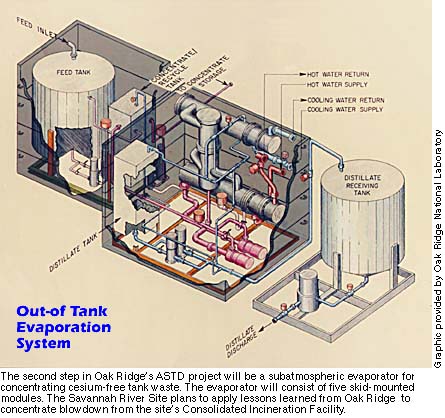

A full-scale demonstration of the subatmospheric

evaporator was also funded jointly by OST and EM-30 at

ORNL in April 1996. This system is composed of five

compact, skid-mounted modules—each having secondary

containment and modular radiation shielding. The

evaporator successfully reduced the volume by 25 percent

of 22,000 gallons of Oak Ridge high-activity tank waste.

CST-the

cutting edge of cesium removal

CST inorganic resins are intended

for one-time use, thus eliminating the secondary waste

generated during reprocessing of organic ion exchangers

and permitting the design and operation of a much simpler

facility. The standard ion-exchange material is organic

resins that remove not only cesium, but similar chemicals

such as calcium and magnesium. Sharon Robinson, technical

lead for the project at ORNL, notes that "CST is

designed specifically to remove cesium; it's highly

selective for cesium. This project will be DOE's first

deployment of CST."

When CST snares hazardous components in addition to

cesium or other radioactive material, it must be treated

as a mixed waste. One way to do this is to vitrify, or

make glass out of, the CST. The Savannah River Technology

Center has determined that CST can be effectively

vitrified if necessary to comply with mixed waste

requirements. Robinson notes that when the cesium removal

unit is used at Savannah River or Hanford, heavy metals

are expected to be in the waste stream. Vitrification at

these sites will be a viable way to encapsulate and

solidify CST. However, the CST used for the ORNL project

isn't expected to contain hazardous materials in addition

to cesium, so vitrification won't be required. ORNL plans

to dispose of its cesium-loaded CST at the Nevada Test

Site.

From

orange juice condenser to tank waste evaporator

Robinson describes the procurement

of the evaporator as "an off-the-shelf

technology" but OST had to adapt the technology for

use in a radioactive environment. Robinson says the

evaporator has been used in the food industry for

condensing orange juice. "You're taking something

from an environment like that to something that is

radioactive where you have to do totally remote

operations, and you're dealing with an entirely different

stream going through the evaporator."

Benefits

of a cesium removal and evaporator merger

The integrated system's first step

is removal of cesium from the tank waste stream, followed

by the evaporator's role of concentrating the resulting

cesium-free waste. Sole reliance on the evaporator would

concentrate cesium in the distillate of the evaporator,

creating a more complicated and less efficient process.

ORNL procured both systems as modular units. Robinson

says "You bring them in, hook them up, put temporary

shielding around them, operate them and then move them to

another site and operate them again." This saves DOE

from developing a huge infrastructure that is not

adaptable to particular wastes and may quickly become

outdated.

Consolidating

tank waste

The cesium removal and evaporator

system is aiding an ORNL effort to consolidate tank waste

and move it from inactive and unsafe facility tanks to

double-shelled tanks. Tank supernates and process water

from sluicing operations will be treated, resulting in

concentrated solutions with lowered radioactive levels.

ORNL issued a call for proposals and is preparing to

award a contract to a private-sector firm for treating,

packaging, and transporting the concentrated tank waste

to the Waste Isolation Pilot Plant, which is not yet

open. DOE's regulatory agreement with the state of

Tennessee requires that all consolidation activities be

completed in FY 2000 to support the privatization effort.

What's

happening now

Oak Ridge is currently phasing in

the implementation of the project. So far this year, ORNL

has installed the evaporator and run it for four

campaigns, during which 83,000 gallons of waste was

reduced by 50 percent. The cesium removal and evaporator

equipment had been tested previously so ORNL has been

buying additional equipment to operate the combined

system in series. Currently, the equipment is being

installed. The plan is to begin operating the integrated

system in series beginning in January 1999 and running

through 2000.

Looking

ahead to Savannah River

The second deployment of the

technologies is planned at the Savannah River Site. ORNL

is now developing the specifications for two SRS

applications that will use each technology separately.

SRS will take the knowledge gained at ORNL and apply it

to its Consolidated Incineration Facility evaporator,

which began processing mixed waste in April of 1997. A

result of this process is a secondary waste stream called

blowdown, containing dissolved solids. Considerable cost

savings can be realized if blowdown can be concentrated

by evaporation before stabilization. The Defense Waste

Processing Facility also emits a recycle stream at the

rate of 3 million gallons per year. A task is currently

under way, using data gained through work done on the

cesium removal demonstration, to establish specifications

for a proposal to create an integrated unit to remove

cesium, mercury, and solids. This reduction of waste

would reduce costs and risks at SRS. Savannah River will

be putting out procurement specifications for the two

systems this fall. ORNL will also evaluate additional

applications past the second deployment. Robinson

believes integrating the systems will require less

energy, reduce foaming and scaling problems, and

ultimately concentrate more waste than the baseline

approach.

Cost

savings

The cost of this project is $21

million spanning four years. ASTD will provide $9.4

million, and the remainder will be EM-30 funds from ORNL

and SRS. Operational costs will be reduced by $84

million, and the remediation schedule at Oak Ridge will

be accelerated by eight years. Additional deployments at

Hanford and Idaho National Engineering and Environmental

Laboratory will substantially increase cost savings.

According to an independent life-cycle cost analysis,

$667 million could be saved if Hanford uses CST ion

exchangers as opposed to the baseline organic ion

exchangers to treat tank supernate.

For more information on the cesium removal and

evaporator ASTD project at Oak Ridge, contact Sharon

Robinson at (423) 574-6779, ssr@ornl.gov.

|