21. Summerfield Boat Works, Inc.

Wash Water Recycled Without Chemicals Environmental change

| Location: | 1500 S.W. 17th Street, Fort Lauderdale, FL 33312 |

| Telephone: | (954) 525-4726; fax: (954) 525-8613 |

| Interviewed: | Tom Correll, General Manager |

| Owned by: | Susan Summerfield Watts |

| Waterbody: | South Fork of the New River |

Environmental change

Boat pressure-wash water is filtered, treated with ozone-not chemicals-then recycled.

The full-service boatyard

Summerfield Boat Works, Inc., is primarily a private commercial boatyard with full and do-it-yourself services. It has 100 slips (60 covered) and 40 land storage spaces (total capacity of 140). Sixty percent of the boats are sailboats and 40% are powerboats, ranging from 21 to 82 feet LOA (average about 40 feet). There are 20 full-time employees year-round and up to 4 additional employees during the prime boating season, October through June.

In addition to offering storage, Summerfield Boat Works caters to seasonal and transient visitors. On a busy weekend, about 30% of the boats are used. Restrooms and showers are available to customers. No liveaboards are allowed. The marina provides haulout and launching with its travel lift, crane, and forklift. Repair services include work on fiberglass, hulls, and engines; sail rigging; painting; canvas/sail making; electronics; welding; carpentry; and hull cleaning. The marina also has a retail parts store, used boat brokerage, pumpout station, and cold beverage stand.

Fort Lauderdale calls itself the "Yachting Capital of the World," and from the numbers of boats and marina facilities, it certainly has earned that title-which means that competition for services is high. Within a 2-mile radius of Summerfield Boat Works there are 10 other marinas and boatyards, all serving a boat population of up to 4,000 vessels. Summerfield was built in 1933 and bought by the Summerfield family in 1940. The yard is located in a residential area that was built after the facility.

Management measures

Summerfield Boat Works complies with the marina management measures for storm water runoff control and solid waste, as well as sewage facility, maintenance of sewage facilities, liquid materials, petroleum control, boat cleaning, and public education.

Costs/benefits

Summerfield Boat Works spent $30,075 to change its boat bottom wash process into a closed water-recycling system. Amortized over 10 years, the annual cost of the system is $3,895. The operation and maintenance cost was $3,800 in 1995. New income generated from 150 boats hauled for bottom cleaning was $18,750, plus an additional $75,000 in work orders. Filtering and reusing wash water saved 24,000 gallons of water, resulting in an estimated saving of $500 in water bills. The net benefit of the investment to Summerfield during 1995 was estimated to be over $86,000.

Environmental improvements

Summerfield Boat Works is an older boatyard that has begun transforming itself into a clean business. The first changes were conversion of the boat high-pressure wash-down process and elimination of in-water hull cleaning. A common practice across the United States was to allow all the bottom washwater, containing fouling growth and paint flecks, to discharge directly into the waterway. When Broward County, Florida, focused on marinas and boatyards, one regulation required the elimination of this discharge or a shut-down of bottom washing.

"In the fall

of 1991, it cost the yard $30,075 to make appropriate changes to clean the wash water

for reuse," Tom Correll said. "We bought a $7,000 water filtering system,

including an ultraviolet light ozone generator to oxidize all the dissolved pollutants

and erase all odor. By choosing ozone to treat the water, the Boat Works eliminated

the need to use chemicals, with their extra cost and hazards."

"In the fall

of 1991, it cost the yard $30,075 to make appropriate changes to clean the wash water

for reuse," Tom Correll said. "We bought a $7,000 water filtering system,

including an ultraviolet light ozone generator to oxidize all the dissolved pollutants

and erase all odor. By choosing ozone to treat the water, the Boat Works eliminated

the need to use chemicals, with their extra cost and hazards."

"We spent $5,000 on labor and $18,000 for the concrete pad and landscaping, plus $75 for a building permit. John Lee, Summerfield Yard Superintendent, really is the one who did the engineering and assembly to make our bottom wash recycle system work."

Annual operation and maintenance costs for this system are $1,000 for filter replacement, $300 for pump parts, and $2,500 in labor, for a total of $3,800 in 1995.

"We annually clean about 1,200 bottoms per year. Of these, new income was generated from 104 boats hauled for yacht surveys and 46 boats that would have been in-water bottom cleaning before, earning $18,750 above previous years. And those same boats generated an additional $75,000 in work orders. I figure that new work was worth a total of $93,750 in 1995."

"We used about 20 gallons of fresh water when washing a bottom, or 24,000 gallons per year," added Correll. "Now that we treat the water and reuse it, we are really saving water, and saving the $500 it would have cost us."

"Without the ozone treatment, the water would have gone bad and smelled. I urge anybody thinking about doing this to buy state-of-the-art equipment rather than making it themselves," added Correll. "By recycling, we are not discharging an estimated 24,000 gallons of wastewater into the river each year. Customers can get their bottoms done here legally, and we have had a good impact on the river's water quality. This has increased our revenues and gives us good references to new customers. And by having us comply, we make government look good when they point to the results of their legislation and enforcement."

All do-it-yourself boat maintenance work is done in designated areas of the yard set back from the bulkhead. Customers receive several handouts that discuss the need to control pollution.

In order to assist with Broward County Office of Natural Resource Protection policy regarding dust emission as well as to help keep the neighborhood and environment as clean as possible, this facility asks your help in controlling the sanding and grinding dust generated during haul out....

Whenever any grinding is to be performed, it will be necessary to drape the work area with tarps in order to prevent the dust from migrating into the air....

Please, do not wash down your sanding dust. Damp rag your hull and vacuum the ground, as required or requested.

Customers are asked to sweep the dust from their work areas daily. Prohibited from the yard are wet sanding of boat bottoms, and wet or dry sandblasting. "I bought a used commercial riding vacuum machine, which I drive throughout the yard every day to pick up any dust and bits of litter. All these new practices do result in cleaner water and neighborhood environment," said Correll.

Other improvements and benefits

Summerfield Boat Works has taken a number of steps to help keep the water clean. Restrooms were recently upgraded. With much of the boat maintenance work do-it-yourself, Summerfield uses flyers and signs to educate customers and outside contractors.

All boats hauled for bottom pressure washing are charged an Environmental Cost Obligation (ECO) above the normal hauling cost. The ECO fee is on a sliding scale: $15 for boats under 35 feet, $20 for boats 35 to 44 feet, $25 for boats 45 to 54 feet, and a top fee of $30 for boats 55 feet and larger.

"This facility is required by law to comply with sound environmental procedures. By charging the wash water fee, Summerfield's is trying to recoup some of the increased costs of compliance with the various regulations. Even though the yard is required to comply with the regulations and management fees, it is important for each to do their share in protecting Florida waters. It also allows the yard to update our equipment and practices prior to being legislated to do so."

Waste oil is collected and recycled. Customers are warned that any oil discharge

is prohibited and "anyone not complying will be promptly reported to the Coast

Guard and EPA." Summerfield removed its old fuel tanks and no longer offers

fuel sales.

|

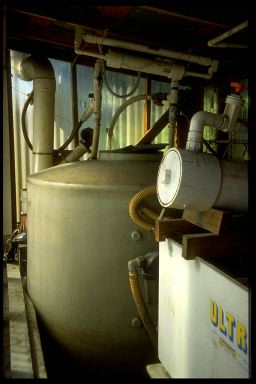

The closed-loop filter and water purification system includes ozone treatment, beside the Summerfield Boat Works' wash down pad. |

Drinking water supply is a major concern in South Florida, and Summerfield Boat Works asks customers to conserve water by limiting boat washing to once a week. "All hoses must have shutoff nozzles attached when in use. All connections must be tight and not leak or drip."

While most of the boatyard was paved many years ago, Correll decided to add a new parking area across the street, and built it unpaved with perimeter landscaping to fit into the neighborhood.

Aluminum cans are collected and recycled for cash. That money goes into a special employees account used for Christmas bonuses. It has created great employee interest in recycling. Paper, batteries, and metal are also recycled reducing the volume that goes to the county landfill.

An enthusiastic customer of the boatyard made a promotional video that highlights the cleanliness of the boatyard and the quality of boat services. The Marine Industries Association of South Florida often refers to Summerfield's as a model operation. Tom Correll is justifiably proud of the clean practices he has implemented at Summerfield Boat Works.

Equipment source

- Ozone equipment: Genesis Environmental Systems, Inc., 1101 South Rogers Circle

#16, Boca Raton, FL 33487.

Alternative source: Turbohydrozone; RGF Marine Environmental Technologies, Inc., 3875 Fiscal Court, West Palm Beach, FL 33404. - Bilge oil pad: Bilge Buddy; Advanced Aquatic Products International, Inc., 1107 Key Plaza, Suite 201, Key West, FL 33040.

| Summerfield Boat Works' vacuum sweeper picks up debris and dirt from boat maintenance areas. |  |

http://www.epa.gov/owow/NPS/marinas/ch21.html

This page last updated October 4, 1999