14. Harbour Towne Marina

Filtered Pressure Wash Water Kept Business

| Location: | 801 Northeast 3rd Street, Dania, Florida 33004 |

| Telephone: | (305) 926-0300, fax: (305) 922-5485 |

| Interviewed: | Gary Groenewold, Florida Regional Manager |

| Owned by: | Westrec Marinas, Inc., Encino, California |

| Waterbody: | Dania Cutoff Canal, off Intercoastal Waterway |

Environmental change

This marina invested in a wash-down filtration system and relocated its hull-cleaning area for environmental compliance.

The full-service and dry stack marina

Harbour Towne Marina is a full-service marina with 150 slips, 365 racks in two large buildings, and 35 dry-land spaces for boats. It operated at 100% of capacity in the 1995 boating season and has 35 full-time employees year-round. Of the boats kept in slips, only five are liveaboards. Ninety-five percent of the boats kept in the marina are powerboats. The boats range in size from under 21 feet up to 80 feet; the average sizes are 45 feet in slips and 24 feet in racks. The largest boat is a 200-foot LOA commercial gambling ship that takes daily cruises offshore.

Before becoming a marina in the 1950s, the land had been used as a U.S. Coast Guard Station since the early 1940s. Westrec purchased the facility in 1989 and has been operating it since. Some services, shops, and offices are leased to other boating-related businesses.

Among the other services available to boaters are transient dockage, launch/haulout, boat rentals, charter boats, new and used boat sales, retail store, fuel dock, pumpout, laundry, food and beverage, and repair services (concessionaires) for fiberglass, hulls, engines, sails, rigging, paint, canvas, electronics, and welding. Westrec does all boat hauling and launching with a travel lift and forklifts. Harbour Towne is the international headquarters of Club Nautico, a small boat rental franchise business. A newly renovated dockside restaurant helps make Harbour Towne a fine marina.

Within a 2-mile radius there are eight other marinas and five boat/shipyards, all servicing an estimated population of 4,000+ recreational vessels. While South Florida has year-round boating weather, the peak season starts in October and runs through April.

Management measures

Harbour Towne Marina complies with the marina management measures for storm water runoff control and solid waste, as well as shoreline stabilization, fueling station design, sewage facility, maintenance of sewage facilities, fish waste, liquid materials, petroleum control, boat cleaning, and public education.

|

| Harbour Towne Marina's 30' by 60' hull power-washing pad. |

Cost/benefits

Design, permit, equipment, and labor costs to build a wash-down pad away from

the launching well, as well as a power wash water filtration system with wastewater

returning to the sewer, required an initial outlay of $46,415.  Annual operation and maintenance of the wash-down

area, including sludge removal, costs $3,300. Gross annual revenue from hauling and

washing boats was $270,000. Assuming a 5% discount rate with costs amortized over

10 years, average annual net income from the hauling/washing operation is estimated

to be $260,689.

Annual operation and maintenance of the wash-down

area, including sludge removal, costs $3,300. Gross annual revenue from hauling and

washing boats was $270,000. Assuming a 5% discount rate with costs amortized over

10 years, average annual net income from the hauling/washing operation is estimated

to be $260,689.

Environmental improvements

Broward County required Harbour Towne Marina, particularly the boat wash-down area within the working boatyard, to comply with its best management practices or to close down that part of the business, with a potential loss of almost $300,000 annually. Permits and design plans cost $3,415. To reduce the chance of spray and bottom debris reaching the marine waters, the washing pad was relocated 100 feet inland from the travel lift well used for haulouts. When the new pad and filtration system were being built, an unanticipated abandoned foundation had to be removed, and a storm water drain tie-in was built ($25,000). Westrec installed a Nova Chem wastewater filtration system ($18,000) to clean the power wash water sufficiently to meet the county's gray water standards for discharge into the municipal sewer system. The project was completed in the spring of 1993.

The system is turned on whenever power washing is being done. The 30-foot by 60-foot concrete washing pad slopes down from the four sides to a large central drain. The pad is hosed down after each hull is cleaned, and all debris and dirt go into the drain and filters. A small mesh cage traps the big pieces of marine growth. The water with dissolved and small particles is pumped into the filter system, where it is further filtered and treated with a series of three different chemicals. Finally, the water leaves the filter and enters a sewer drain. It costs $3,300 to operate and maintain the wash-down area, including sludge removal, chemicals, and labor.

When asked what he would do differently, Groenewold said, "I would research the site better. For a smaller yard, I would tailor the system to the site and lower the cost by using plastic tubs instead of stainless steel tanks."

When it rains in South Florida, it really pours, and such a volume of runoff could not be allowed to enter the filter. Since the pad is always kept clean, contamination of runoff is not a problem. Thus, a drain bypass system was installed to allow rainwater to drain into the adjacent mangrove swamp.

During the 1994-95 season, Westrec hauled and washed 650 boats, which brought in $270,000 income. Groenewold added, "We couldn't be in the boat-handling business without approval for our new pad and filtration system. We could not allow contamination to continue. More than any other thing the marina can do, we can keep wash water from returning to the canal."

The marina employs a number of other best management practices consistent with the Broward County BMPs. "Copies are given to all outside contractors and commercial tenants with contract language requiring their compliance," said Groenewold, "and the contractors must each agree to the terms and sign the contract before doing any work on our property. Discharge of sewage is forbidden, and the use of oil bilge pads encouraged. Recycling is available for oil, batteries, plastic, glass, cans, zinc, and other metal scraps. Signs and a fish-cleaning station also are found in Harbour Towne. Every boat owner gets a two-page 'Environmental Awareness Contract' stating the marina's requirements on sewage discharge, bilge water, fuel, and boat maintenance, and a hurricane preparedness plan." The latter is an interesting inclusion because severe storms can do much physical damage, which results in environmental contamination. At Harbour Towne, storm and environmental preparation go hand in hand.

The fuel and pumpout dock were recently modernized, and extra fire and spill control equipment was added. Boaters are required to have oil absorption pads in the bilge. Pumpouts are free for slip customers, and a $5 fee is charged for outside boats. Hand washing of vessels is permitted in slips only if biodegradable soap is used in minimal amounts.

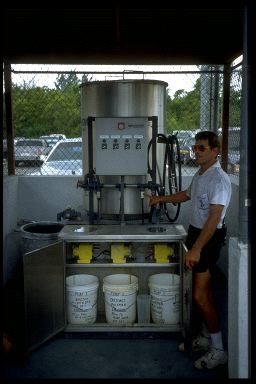

|

| This power-wash water filtration, clarification, and flocculation system allows Harbour Towne Marina to discharge the greywater into the municipal sewer system. |

To further reduce runoff contamination, the entire perimeter of the marina (except the launching areas, commercial work building frontage, and fuel dock) was dug up and planted with a greenbelt of grass. Grassy traffic islands with trees were built in the large car parking lots. The green foliage and lawns help ease the visual impact of the large facility, act as runoff filters, and give some cooling effect from otherwise fully paved though very clean land.

http://www.epa.gov/owow/NPS/marinas/ch14.html

This page last updated October 4, 1999