"Precision Cleaning - The Magazine of Critical Cleaning

Technology"

Parts Cleaning Carbon Dioxide Snow Examination and Experimentation

by: Elizabeth A. Hill

Pages: 36 - 39; February, 1994

When liquid carbon dioxide (CO2) is allowed to expand to

atmospheric pressure through a nozzle, a portion of the CO2 freezes,

forming soft flakes. Spray cleaning surfaces with this CO2

"snow" has been shown to remove particles and other debris without

damage.

This technique was initially proposed for precision cleaning applications

more than five years ago.1 Since then it has been used on component

surfaces of instruments ranging from telescopes2 to vacuum

systems.3

Carbon dioxide snow can also be compressed into hard pellets that are

propelled toward a surface with high-pressure gas as a carrier. In this form,

the pellet process resembles sandblasting and can remove paint and rust. Care

must be taken with pellet blasting, however, to avoid physical damage to the

surface being sprayed.

This article focuses on the gentler, snow cleaning process.

Various Advantages, Various Approaches

One advantage of CO2 cleaning is that the snow sublimes, leaving

behind as waste only the removed debris. This can greatly reduce waste disposal

costs. Other advantages are that the equipment and process for cleaning with

CO2 snow are very simple and relatively inexpensive.

Carbon dioxide is nontoxic, nonflammable, and does not deplete the ozone

layer. It is a greenhouse-warming gas, but is collected as a by-product of

other processes, so there is no net increase of carbon dioxide emissions into

the atmosphere.

Snow made from water or argon also have been used for surface

cleaning.4,5 When using water snow, the parts being cleaned become

wet and must be dried in subsequent process steps.

The water-based snow cleaning process must be performed in an area where the

resulting liquid can be controlled and collected. The major advantages of this

method are that water is readily available in high purity and is not a

greenhouse warming material.

Argon had identical advantages. However, argon snow (-189.3° C freezing point) is much colder than

CO2 snow (-78.5° C freezing point),

so thermal shock and chilling of the parts is more of a problem.

With both water snow and argon snow, more equipment is needed to operate the

process than with CO2 snow. For argon snow, the argon gas must be

precooled and pressurized prior to expansion, or the snow will not form. The

process also is carried out in a vacuum chamber to prevent condensation on the

part. It is usually performed under partial vacuum to maintain the argon

particles in a solid state and allow then to reach the surface more

effectively. CO2 snow requires only a liquid carbon dioxide source

and nozzle.

Experimental Setup and Procedures

High-purity CO2 in a standard 50-pound, 800 psi tank was used for

these experiments. A nozzle or snow gun was attached to the tank with a

braided, stainless steel-jacketed hose. A purifier was connected in series

between the tank and gun. The gas used in most tests was Air Products and

Chemicals' (Allentown, Pa.) high-purity grade. The nozzle and purifier were

supplied by Va-Tran Systems, (Chula Vista, Calif.).

The surfaces cleaned in these experiments were unpatterned silicon wafers.

Particles on the wafer surfaces were counted and sized with an Aeronca WIS-150

laser wafer scanner before and after snow cleaning.

Particle removal experiments were performed on wafers pre-contaminated with

0.31, 0.50, and 0.94 micron polystyrene latex (PSL) microspheres and Arizona

fine test dust. The contaminants were deposited on the wafers by producing a

cloud of the particles above the wafers and letting it settle on them. Addition

of other contaminants was measured on clean wafers (no pre-contaminated with

particles), also with the WIS-150.

To begin a cleaning cycle, the nozzle valve was opened. Gas flowed from the

system until it cooled to the point where snow was produced. One snow was

spraying from the gun at a steady rate, it was directed at the parts being

cleaned.

The operator moved the gun across the surface in a manner similar to washing

a car with a hose. For all tests, the nozzle's tip was positioned at a standard

45° angle approximately 3 inches from the

surface. As long as the snow hit all surfaces to be cleaned, distance and angle

were not critical. A standard cleaning cycle lasted 10 seconds.

Removal of Particles

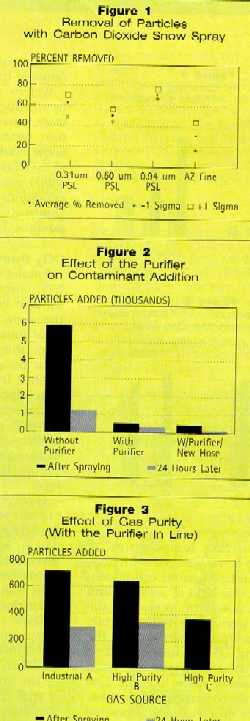

Figure 1 shows the percent of particles removed from the wafer. Error

bars for +/- one standard deviation (sigma) are included.

The CO2 snow removed 55 to 75 percent of the PSL microspheres;

about 32 percent of the Arizona fine test dust was removed. The latter

particles have a maximum size of 176 microns, with more than 50 percent of the

particles being smaller than 10 microns, and 18.2 percent smaller than 2.8

microns. The initial loading of Arizona fine test dust on the wafers was very

heavy.

The true particle removal percentages were probably slightly higher than

those shown here. Some addition of contaminants from the CO2 was

occurring concurrently with the cleaning, but every effort was made to minimize

this problem during these tests.

These values are indicative of the process capability, since the desired

result is the lowest overall particle count possible, whether from prior

contamination or that from the cleaning process. The next experiments in this

study focused on the material being added to the wafers by the CO2

and methods to reduce or eliminate it.

Addition of Contaminants

The snow cleaning process currently does add some contamination to the parts

being cleaned -- seen on the wafer surfaces as very small, thin droplets, most

of which are less than 0.5 microns in diameter.

The wafer scanner does detect them and counts them as particles. The

droplets are not easily seen with a light microscope because they are small and

widely dispersed on the surface. Nomarski polarization is helpful. A Scanning

Electron Microscope (SEM) does not detect the droplets, possibly because they

are not stable in vacuum or are destroyed by the electron beam.

Much of the material is volatile. Therefore, all data reported in this

section include particles added to the wafers as measured immediately after

spray cleaning, and as remeasured 24 hours later. The sources of this

contamination were traced to the gas supply and some of the components in the

cleaning apparatus. A purifier was used in these experiments to reduce the

contamination.

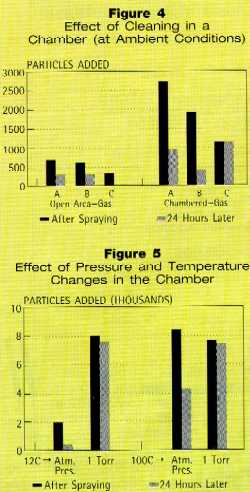

Figure 2 shows the addition of particles to the wafer with the

without the purifier in line. The purifier reduced the amount of contamination

from the gas sources by 75 to 90 percent. The major portion of the remaining

material was identified as phthalic and aliphatic esters, traced to a hose

upstream of the purifier. Upon replacement with a teflon-lined hose,

contamination reduction improved to 90 to 94 percent. There is still a small

amount of contamination added, but efforts are currently underway to eliminate

this as well.

Effects of Gas Purity, Enclosed Cleaning

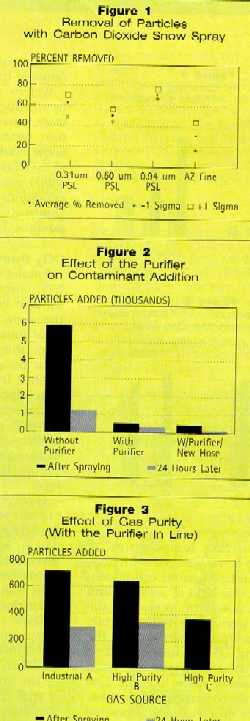

Figure 3 shows the effect of gas purity. Three different gas sources

were tested: "A" was an industrial grade; "B" and

"C" were high-purity gas sources from different suppliers. All three

were used with the purifier in line.

The wafers from gas "C" were not scanned after 24 hours, so the

graph includes no data for that gas source. Small differences in the amounts of

contamination added to the wafers from the different gas sources were much

greater without the purifier in line. This shows that the purifier is effective

in reducing contaminants from the gas but that gas quality is still important.

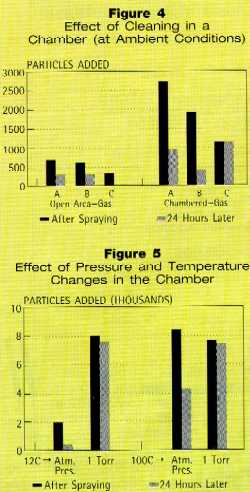

Figure 4 shows the effect of cleaning inside an enclosed space.

Wafers were placed on a support inside a stainless steel vacuum chamber, and

the snow gun nozzle was fixtured through the chamber wall. All other conditions

were maintained. No vacuum was pulled in these tests. The wafers cleaned out in

the open were placed on a support several inches above the surface of a table

so that the snow slid off the wafer as it cleaned. Cleaning in the open results

in much less addition of contamination than in an enclosure.

The most striking result was that the snow cleaning the wafers

simultaneously cleaned the walls of the vacuum chamber. The snow spray aimed at

the wafer would bounce off the wafer and swirl around in the chamber. Some

flakes than hit the chamber walls and rebounded back onto the wafer, depositing

contamination.

Effect of Pressure and Temperature

To study the snow cleaning mechanism, wafers were sprayed while at two

temperatures and two pressures.

The first cleaning tests were done in an open area. Wafers were mounted on

heating blocks and cleaned while maintained at 15° C and 100° C. There

were no significant differences in the amounts of contamination added to wafer

surfaces.

Next, clean wafers were placed in a vacuum chamber. The temperature of the

wafers was held at 12° C and 100° C for these tests. Figure 5 shows the

results of cleaning wafers in the vacuum chamber while at the two temperatures

and pressures.

When the wafers inside the chamber were heated to 100° C on a heating block, the added contamination was

much greater than at the lower temperature. This may be attribute primarily to

chamber wall cleaning as well as increased phase change at the wafer surface

due to the higher surface temperature.

Wafers also were sprayed with CO2 snow while under vacuum

conditions. The pressure was held at ambient and 1 torr. At atmospheric

pressure, the snow flakes were large and discrete, and could easily be seen

during spray cleaning. At vacuum of 1 torr, the snow particles were very small

and indiscrete, looking more like fog. Low pressure inhibits coagulation of

particles.

Many more droplets were deposited on the wafer surfaces in vacuum, and a

much larger percentage of those remained on the surfaces 24 hours later. This

may have been thermal mass and more surface area to volume, changes phase at

the surface of the part being cleaned, dropping the contaminants from the gas

source. The source of the increase in solid, non-volatile particles appeared to

be debris removed from the inside of the chamber.

Wafers cleaned with both elevated temperature and reduced pressure also were

heavily contaminated. It appears that conditions producing short-lived snow

flakes (vacuum or the combination of a heated substrate and enclosing walls)

should be avoided, as well as conditions where the snow flake is contaminated

prior to reaching the surface being cleaned.

CO2 Snow Cleaning Mechanisms

Among two possible mechanisms for CO2 snow cleaning is transfer

of kinetic energy by physical contact of the snow flakes with the particles. A

flake must hit a particle and knock it from the surface. The particle must then

be entrained in the gas jet and flushed from the surface being cleaned. It is

important for solid snow flakes to be present in the CO2 gas jet. A

gas blow-off alone will only remove large particles, leaving smaller particles

behind in the area of low gas velocity near the surface known as the boundary

layer.

However, this mechanism does not explain some of the experimental findings

described in the next paragraphs, which leads to the next proposed mechanism: a

combination of shear stress forces and thermophoresis.

In this explanation, the solid snow flake does not physically contact the

particle or the surface being cleaned. The approaching snow flake is separated

from the surface by a cushion of cold CO2 gas produced by

sublimation of the snow flake. There may even be a thin layer of liquid or

supercritical CO2 between the solid CO2 and the gas

during the brief time the flake is nearest to the surface.

Particles on the surface being cleaned are exposed to shear stresses from

two sources. The first is the gas flowing from the nozzle. However, the force

of this gas is not dominant or even required in this removal mechanism.

The second and more important source of shear stress energy is the rapid

expansion of carbon dioxide as the snow flake changes phase from solid to gas.

As the cold snow flake approaches the surface it is exposed to a large, much

warmer thermal mass (the surface). The solid snow rapidly changes phase on the

side nearest to the surface.

There is a very small distance between the flake and the surface for this

material to expand in as it changes to gas, so a high velocity burst is

created. This explosive phase change occurring in the small distance between

the snow flake and the surface provides the force necessary to dislodge the

particle.

One the particle is dislodged it is attracted and held to the snow flake by

thermophoretic forces. Thermophoresis refers to the force on a particle due to

a thermal gradient. The kinetic energy of air molecules on the cool side of a

particle is less than on the warm side. Therefore, warm air molecules

"push" the particle in the cool direction. The greater temperature

difference and the smaller the distance between warm and cold points, the

stronger the force.

With snow cleaning, there is approximately 100° C difference in temperature over the distance of a

few microns or less. Thermophoretic forces are usually incapable of overcoming

particle-to-surface adhesion, but are strong enough to account for entrapment

of particles in the snow flakes. These particles are held to the snow flake as

long as it remains in solid phase, and will be deposited when the change to gas

phase is complete.

This hypothesis is supported by several experimental observations. First,

when large snow flakes (roughly one-eighth-inch diameter and up) are sprayed up

into the air and allowed to settle back onto the surface being cleaned, the

particles are still removed. This eliminates the shear forces due to the gas

flow from the nozzle.

Second, particles removed from a surface by snow flakes are redeposited

wherever the snow finally changes back to the gas phase. A small pile of snow

flakes can be collected and picked up with a spatula. If this pile is placed on

a contaminated surface and then lifted off again, the particles are removed

from the surface. If the same snow pile is then placed on a clean surface and

allowed to sit until it sublimes, the particles are redeposited at that point.

Some nozzles produce a small jet of high-velocity, small snow flakes. Others

produce large qualities of large, low-velocity snow flakes. Experience has

shown that different cleaning results are obtained with the two types of snow

nozzles. This may be due to differences in the dominant cleaning mechanism.

Nozzles producing higher velocity jets with smaller snow flakes may result in

more kinetic cleaning, while the forces from larger snow flakes may be due to

thermophoretic cleaning.

Conclusions

Carbon dioxide snow cleaning is effective for particle removal, and should

be considered among alternative cleaning processes.

The best cleaning is obtained when using high-purity gases and mechanical

components. Cleaning should be performed at room temperature and ambient

pressure. Surfaces should be cleaned with smooth, quick strokes. The snow must

be allowed to leave the surface being cleaned before it changes to the gas

phase.

The CO2 cleans everything it contacts, including the inside of

the gas tank, the hoses, and nozzles in the cleaning apparatus. Therefore, all

components in the gas delivery system and spray nozzle must be clean. The inner

surfaces of the hoses and nozzles must be as smooth as possible and be made of

non-flaking and non-leaching materials. Use of dedicated gas tanks and system

components is highly recommended to maintain cleanliness.

The main challenge with this technique as it stands today is eliminating the

last microdroplets of contamination, identified as being primarily from the

CO2 gas itself. If this flaw can be eliminated, CO2

cleaning will be feasible for many processes requiring very high levels of

cleanliness.

In the meantime, CO2 cleaning is still viable for many processes,

such as removal of packaging debris, cleaning of equipment before entry into

cleanrooms, and removal of particles from surfaces where submicro organic

droplets will not harm product submission.

References

1. S.A. Hoenig, "Cleaning Surfaces with Dry Ice,"

Compressed Air Magazine, No. 8,9122-24, August 1986.

2. R.R. Zito, "Cleaning Large Optics with CO2 Snow",

SPIE, Vol. 1236 Advanced Technology Optical Telescopes IV 1990.

3. L. Layden and D. Wadlow, "High Velocity Carbon Dioxide Snow for

Cleaning Vacuum System Surfaces," J.Vac Sci. Technol., A 8 (5), 3881-3883,

Sept./Oct. 1990.

4. T. Ohmori, I. Kanno, T. Fukumoto, H. Komiya, M. Tada, T. Kawaguti,

"Ultra Clean Ice Particles," J. Electrochem. Soc. 137, 399C,

1989.

5. W. T. McDermott, R. C. Ockovic, J. J. Wu, R. J. Miller, "Surface

Cleaning by a Cryogenic Argon Aerosol," Proc. Of the IES. 882-885,

1991.

Acknowledgments

The author wishes to thank the sponsors and affiliates of the Surface

Cleaning Technology Consortium (SCTC) and the Research Triangle Institute who

jointly supported this work. Sponsors included IBM, Fujitsu, Kobe Steel Ltd.,

and Storage Technology Corp. Affiliates included Allied-Signal, Crest

Ultrasonics, The J.M. Ney Co., TSI Inc., UVOCS, Va-Tran Systems, and Verteq.

The CO2 snow equipment was provided by Va-Trans Systems. In

addition, the support of the surface cleaning laboratory staff is greatly

appreciated.

About the Author

Elizabeth A. Hill is the program manager for the Surface Cleaning

Technology Program in the Center for Aerosol Technology at Research Triangle

Institute (RTI), N.C. She received bachelor's (1978) and master's (1981)

degrees in analytical chemistry from Northern Illinois University and the

University of Colorado, respectively. Before joining RTI, she gained seven

years of industrial experience in precision surface cleaning and contamination

control as a development and manufacturing engineer in the computer disk drive

industry.

Best Conditions for Snow Cleaning

The following conditions enhance particle removal and minimize contaminant

addition.

- Use a high-purity gas source.

- Use a purifier in-line for additional purity and quality control.

- Clean at ambient temperature and pressure.

- Clean in an open area so that the snow strikes only the part being cleaned

and can be collected before it changes phase.

- Move the nozzle slowly and smoothly across the surface once, making sure

that the snow does not pile up on the part being cleaned. Cleaning is not

improved by holding the gun closed to the surface or holding it in one place

for a long time. Further exposure only chills the part being cleaned and

produces additional gas-sourced contamination.

- Ensure that there are no materials in the cleaning system that could leach

organics into the CO2.

|